Aqueous liquid eye shadow and preparation method thereof

A water-based liquid and eye shadow technology, which can be applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of poor makeup retention, sticky skin feeling, dry powder, etc., and achieve good makeup retention and skin feel. Excellent, skin-protecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A water-based liquid eye shadow, comprising the following components by mass percentage:

[0031] Disodium EDTA 0.02%, Butylene Glycol 1%, Glycerin 3%, Carbomer 0.4%, Polyacrylate-13, Polyisobutylene and Polysorbate-20 0.2%, Phenoxyethanol 0.2%, 1,2-Hexanediol 0.3%, Ethylhexylglycerin 0.3%, Polyurethane-35 3%, Styrene / Acrylate Copolymer 3%, Pearlescent Powder 8%, Rose Water 0.4%, Cactus Extract 0.5%, Calendula extract 0.4%, water balance.

[0032] The preparation method of this aqueous liquid eye shadow comprises the following steps:

[0033] Disperse the carbomer in water, fully swell, then add disodium edetate, butanediol and glycerin to mix evenly, under constant stirring, add 1,2-hexanediol, ethylhexylglycerin, benzene oxyethanol, polyurethane-35, styrene / acrylate copolymer, pearl powder, rose water, cactus extract, calendula extract and polyacrylate-13, polyisobutylene and polysorbate-20, The result is a water-based liquid eyeshadow.

Embodiment 2

[0035] A water-based liquid eye shadow, comprising the following components by mass percentage:

[0036] Disodium EDTA 0.03%, Butylene Glycol 3%, Glycerin 1%, Carbomer 0.2%, Polyacrylate-13, Polyisobutylene and Polysorbate-20 0.2%, Phenoxyethanol 0.1%, 1,2-Hexanediol 0.2%, Ethylhexylglycerin 0.2%, Polyurethane-35 1%, Styrene / Acrylic Copolymer 1%, Pearl Powder 6%, Rose Water 0.2%, Cactus Extract 0.2%, Calendula extract 0.5%, water balance.

[0037] The preparation method of this aqueous liquid eye shadow comprises the following steps:

[0038] Disperse the carbomer in water, fully swell, then add disodium edetate, butanediol and glycerin to mix evenly, under constant stirring, add 1,2-hexanediol, ethylhexylglycerin, benzene oxyethanol, polyurethane-35, styrene / acrylate copolymer, pearl powder, rose water, cactus extract, calendula extract and polyacrylate-13, polyisobutylene and polysorbate-20, The result is a water-based liquid eyeshadow.

Embodiment 3

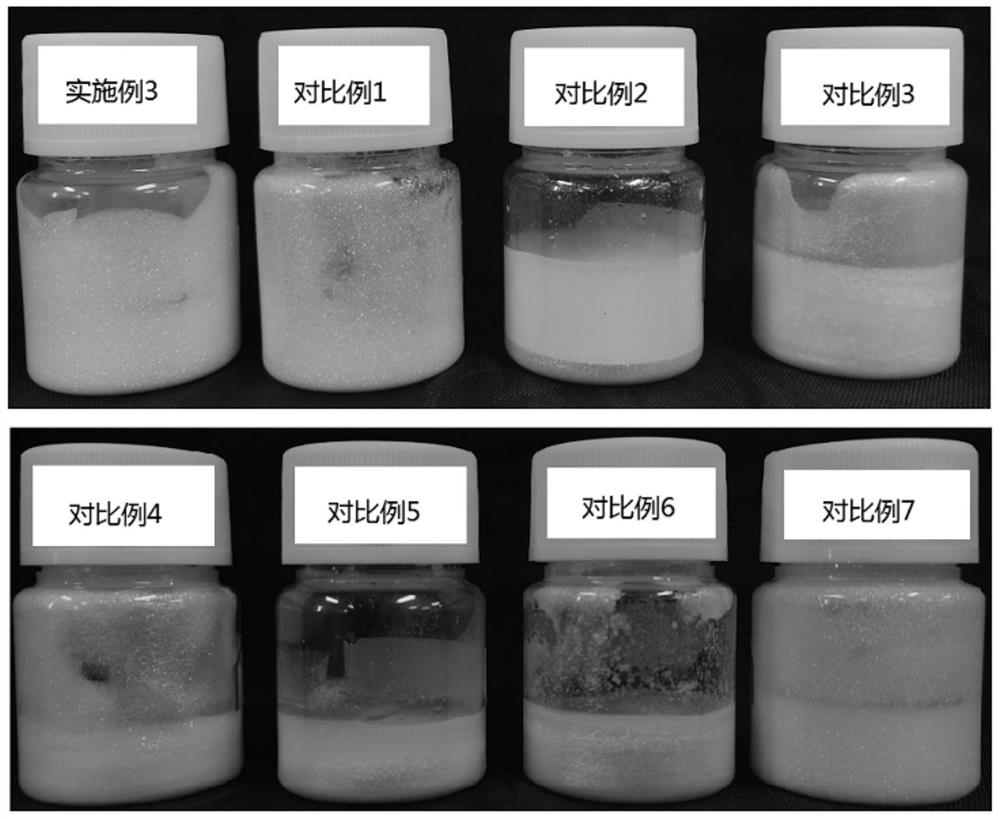

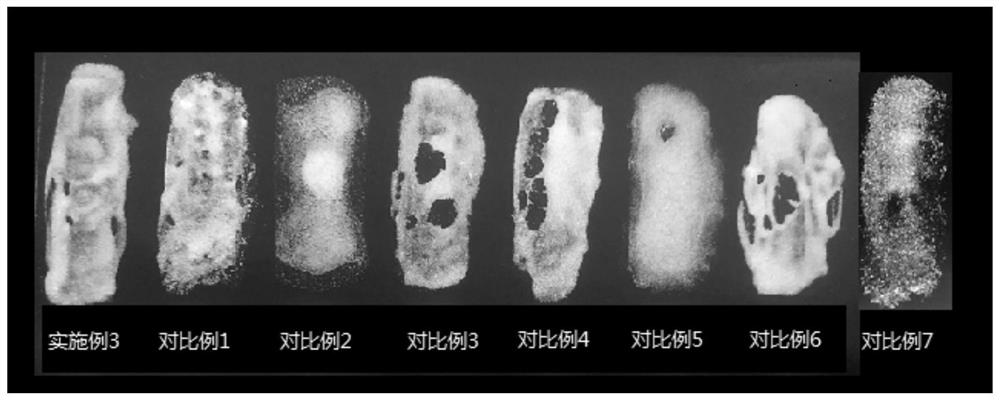

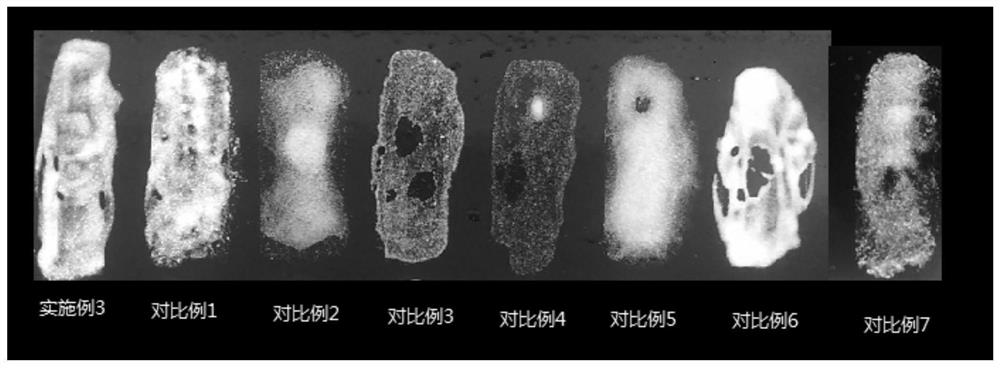

[0039] For the water-based liquid eye shadows of Example 3 and Comparative Examples 1-7, the formula components are shown in Table 1 in terms of mass percentage.

[0040] Table 1

[0041]

[0042]

[0043] It should be noted that in Comparative Examples 3-6, when the addition amount of xanthan gum or hydroxyethyl cellulose was 0.3%, it was unable to achieve sufficient thickening effect and suspend pearl powder, so that water-based liquid eye shadow could not be prepared. , so the addition of xanthan gum or hydroxyethyl cellulose should be increased to at least 1% to prepare water-based liquid eye shadow.

[0044]The preparation method of the aqueous liquid eye shadow of embodiment 3 may further comprise the steps:

[0045] Disperse carbomer in water and swell fully, then mix the processed carbomer with other ingredients in phase A according to the proportion, after mixing evenly, add phase E, C, D, and F under constant stirring And polyacrylate-13, polyisobutylene and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com