Rare earth-containing ilmenite type welding rod and preparation method thereof

A technology of rare earth titanium and welding rods, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of easy slag inclusion, poor impact toughness, incomplete penetration, etc., to improve comprehensive performance, increase tensile strength and Effect of impact toughness and homogenization of austenite grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

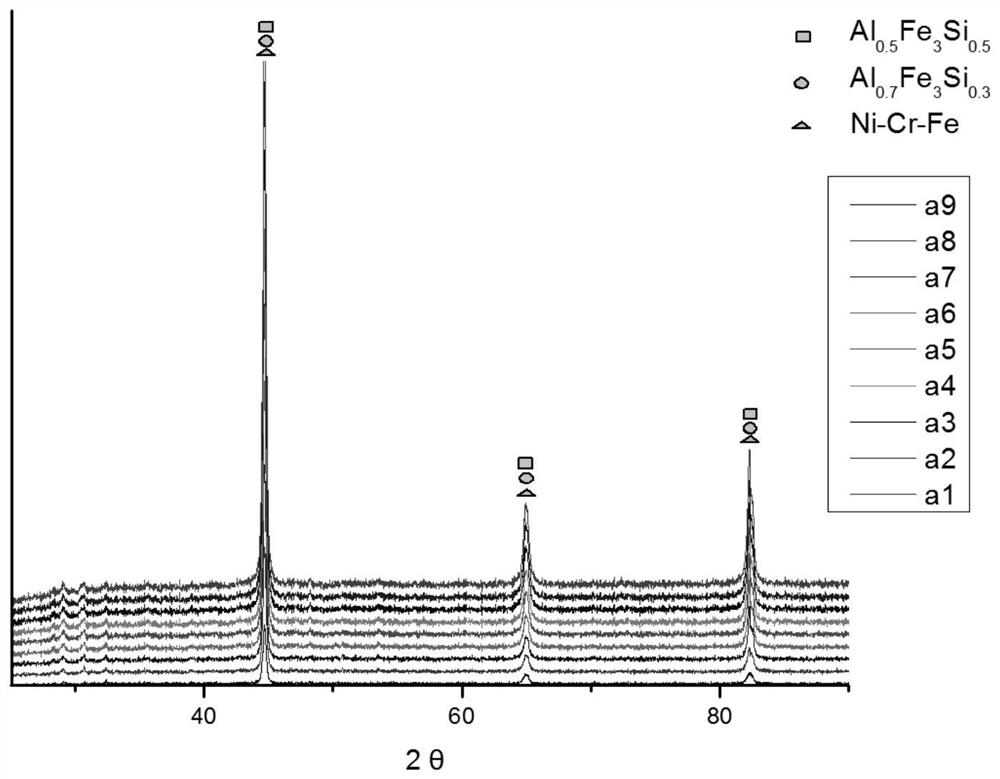

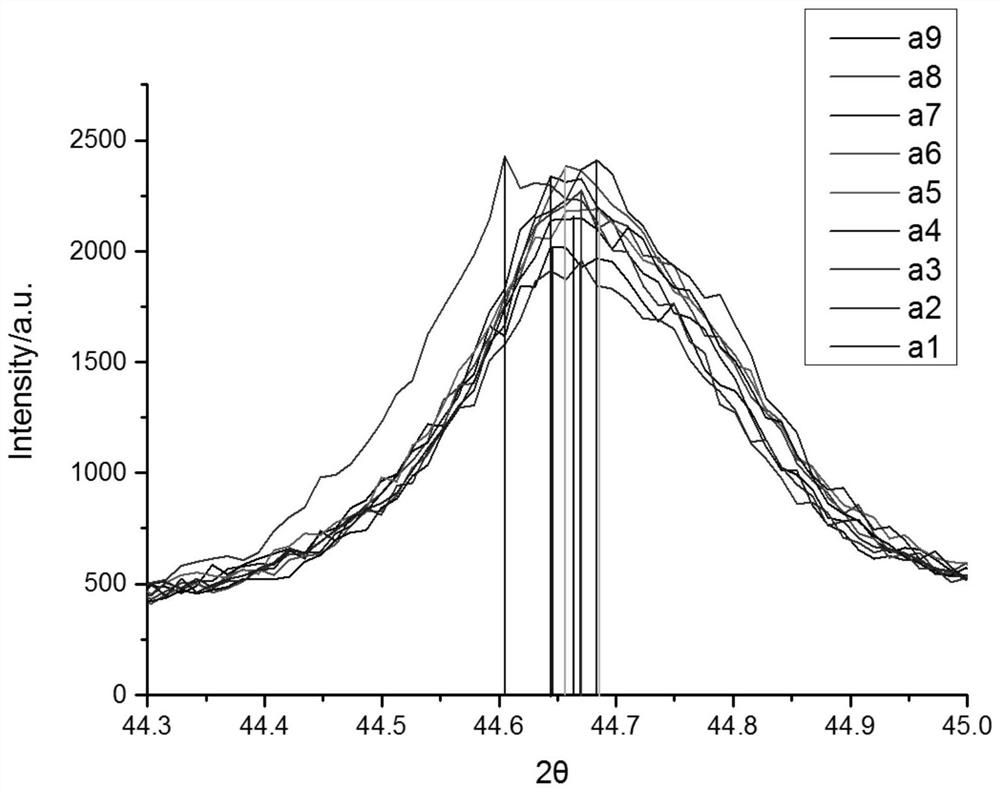

Image

Examples

preparation example Construction

[0027] For the preparation process of reduced ilmenite, what this application adopts is, after the ilmenite is screened earlier, add composite additives (i.e. analytically pure sodium chloride and sodium tetraborate) and binding agent (i.e. industrial pure silicic acid Sodium) after regrinding and moistening, and prepare composite pellets according to the appropriate pelletizing process parameters. After the pellets are pre-oxidized, add an appropriate amount of coke and fill them in a tube furnace for reduction. The reduction product is passed through an inert gas After cooling, the reduced pellets, residual carbon and ash are separated, and the reduced pellets are broken into corresponding particles to obtain reduced ilmenite for welding rods. Specifically include the following steps:

[0028] 1. Preparation of composite pellets After sieving, the ilmenite ore is screened, and 40 mesh ore is selected for regrinding. The particle size is ground to less than 140 mesh, which ac...

Embodiment 1

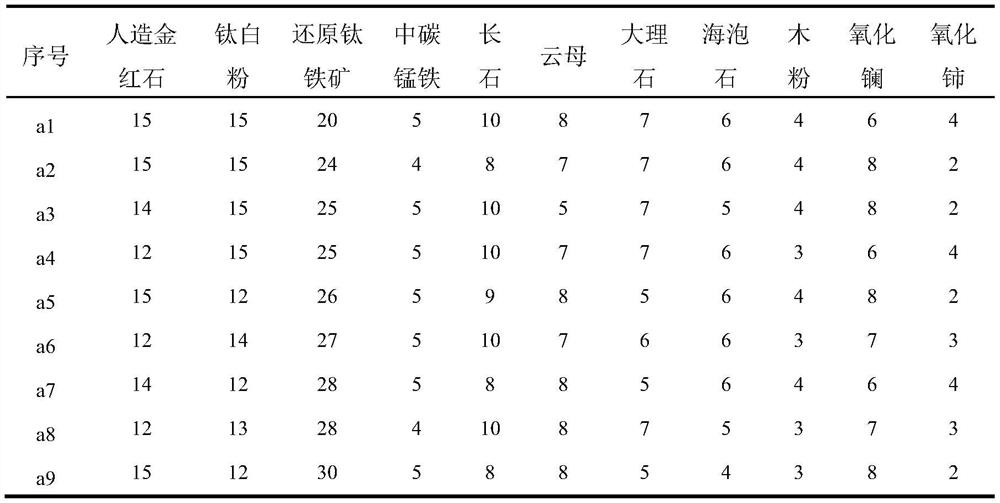

[0051] The welding core is H08A, and the weight percentage of the coating is shown in the following table 1 to make 9 welding rods:

[0052] Table 1 Specific experimental formula design (wt.%)

[0053]

[0054] When preparing the welding rod, grind the Φ3.2H08A welding core with sandpaper to remove rust, straighten it, and set it aside. Mix the various medicinal powders weighed above together, stir thoroughly, and there must be no lumps or granules. Gradually add appropriate amount of water glass and mix gently until a "dough" can be formed. Knead the wet powder along the welding core bit by bit, pay attention to the force evenly, roll it gently on the glass after kneading, so that the coating is even, and leave about 20mm of no coating at one end of the welding rod end, the non-clamping end leaves the solder core, do not form a header. The twisted electrodes are dried in the air for 24 hours, and then placed in an oven for 2 hours at 180°C to 220°C.

[0055] The compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap