Concrete glue reducing agent and preparation method thereof

A technology of concrete and adhesive reducer, which is applied in the field of concrete admixtures, can solve the problems of high preparation environment requirements, and achieve the effects of stable preparation process, simple operation and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

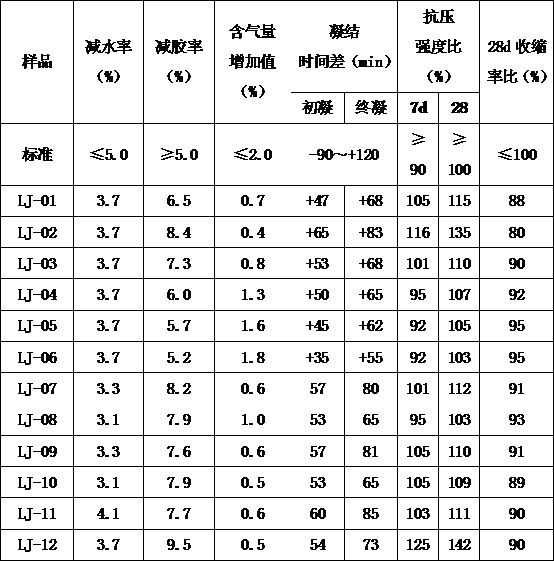

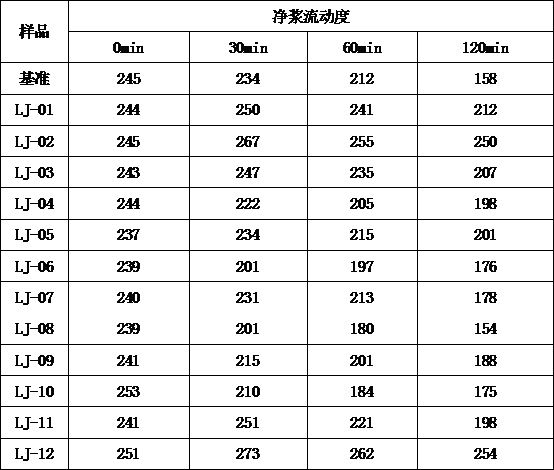

Examples

Embodiment 1

[0031] The preparation method of the present embodiment carboxylic acid concrete glue reducer is as follows:

[0032] 1) Mix 85.0g methallyl polyoxyethylene ether (C4), 170.0g isopentenol polyoxyethylene ether (C5), 85.0g GPEG (C6), 32.5g sodium hypophosphite, 10.8g isopropanol , 10.8 g of sodium methylpropene sulfonate, 10.8 g of 30% H2O2, and 148.0 g of water were respectively put into a four-necked flask, and the stirring was started, the condensed water was turned on, and heated to 65°C until all dissolved;

[0033] 2) Add the mixed solution containing 43.3g of itaconic acid, 202.8g of methacrylic acid, 44.6g of water and the mixed solution of 2.35g of vitamin C and 131.4g of water into the four-necked flask respectively, and the dropping time is controlled at 2.5 h, after the dropwise addition, add 24.5g of 2-acrylamide-2-methylpropanesulfonic acid, heat to 85°C, continue to stir for 2h, adjust the pH to 6.0-7.0 with trisodium phosphate, and prepare glue reducer LJ-01 . ...

Embodiment 2

[0035] The preparation method of the present embodiment carboxylic acid concrete glue reducer is as follows:

[0036] 1) Mix 85.0g methallyl polyoxyethylene ether (C4), 85.0g isopentenol polyoxyethylene ether (C5), 170.0g GPEG (C6), 32.5g sodium hypophosphite, 10.8g isopropanol , 10.8g of sodium methacrylate, 10.8g of 30% H2O2, and 148.0g of water were respectively put into a four-neck flask, and the stirring was started, the condensed water was turned on, and heated to 65°C until all dissolved;

[0037] 2) Add the mixed solution containing 43.3g of itaconic acid, 202.8g of methacrylic acid, 44.6g of water and the mixed solution of 2.35g of vitamin C and 131.4g of water into the four-necked flask respectively, and the dropping time is controlled at 2.5 h, after the addition is completed, add 24.5g of 2-acrylamide-2-methylpropanesulfonic acid, heat to 85°C, continue to stir for 2h, adjust the pH to 6.0-7.0 with trisodium phosphate, and prepare the glue reducer LJ-02.

Embodiment 3

[0039] The preparation method of the present embodiment carboxylic acid concrete glue reducer is as follows:

[0040] 1) Mix 170.0g methallyl polyoxyethylene ether (C4), 85.0g isopentenol polyoxyethylene ether (C5), 85.0g GPEG (C6), 32.5g sodium hypophosphite, 10.8g isopropanol , 10.8 g of sodium methylpropene sulfonate, 10.8 g of 30% H2O2, and 148.0 g of water were respectively put into a four-necked flask, and the stirring was started, the condensed water was turned on, and heated to 65 ° C until all dissolved;

[0041]2) Add the mixed solution containing 43.3g of itaconic acid, 202.8g of methacrylic acid, 44.6g of water and the mixed solution of 2.35g of vitamin C and 131.4g of water into the four-necked flask respectively, and the dropping time is controlled at 2.5 h, add 24.5g of 2-acrylamide-2-methylpropanesulfonic acid after the addition is completed, heat to 85°C, continue to stir for 2h, adjust the pH to 6.0-7.0 with trisodium phosphate, and prepare the glue reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com