A preparation method of nanometer tungsten oxide electrochromic film

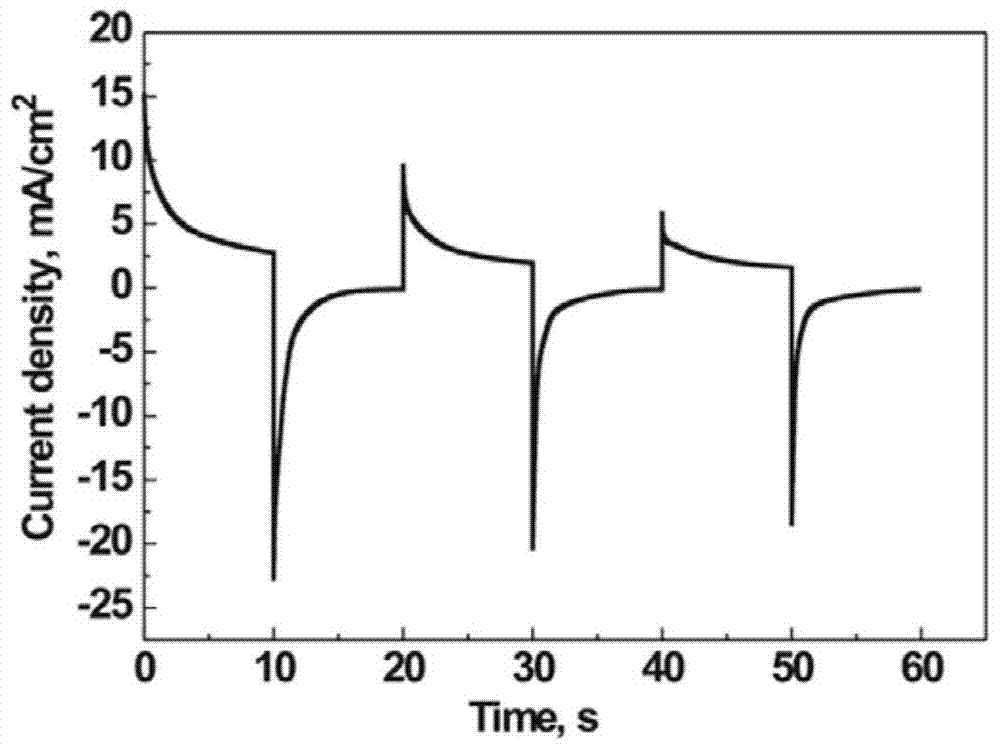

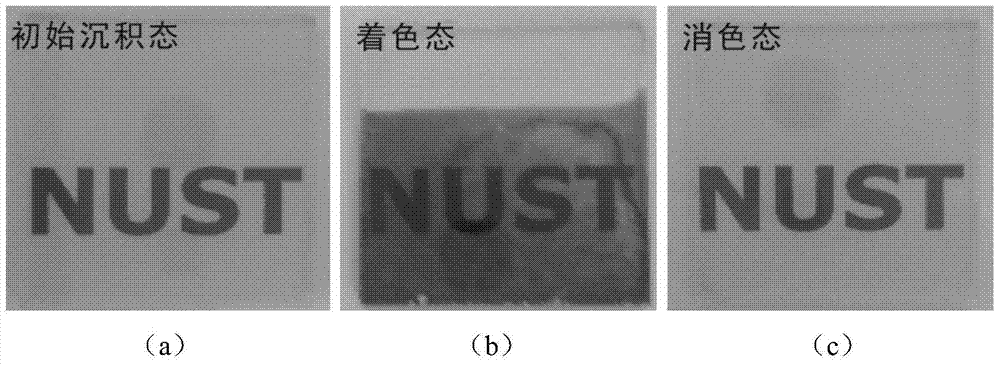

A nano-tungsten oxide and electrochromic technology, which is applied in the field of preparation of nano-tungsten oxide thin films, can solve the problems of inability to achieve fast response speed, low performance of electrochromic devices, and low film quality, etc. The effect of high achromatic contrast and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

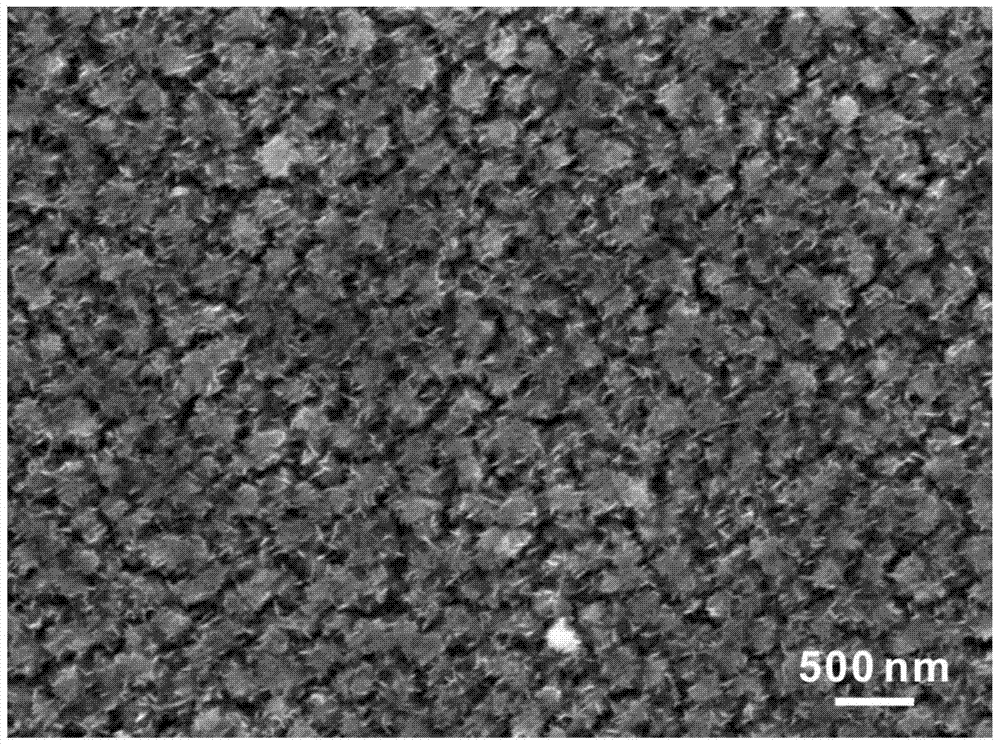

[0026] Combining liquid-phase laser ablation technology with electrophoretic deposition method to prepare nano-tungsten oxide film, first ablate the tungsten source target by liquid-phase laser to obtain a colloidal solution containing tungsten oxide nanoparticles; Depositing on a transparent conductive glass substrate to prepare a nano-tungsten oxide film specifically includes the following steps:

[0027] Step 1, add the prepared H concentration of 0.33% in the reaction vessel 2 o 2 solution, put a tungsten target with a purity of 99.99% in H 2 o 2 solution, and soak the solution over the surface of the target, and use a magnetic stirrer to stir the solution evenly.

[0028] Step 2. Adjust the optical path of the pulsed laser beam of the laser, so that the laser beam is focused on the target below the solvent liquid level, and a laser with a wavelength of 1064nm is selected to ablate the tungsten target. The laser working frequency is 10Hz, and the laser ablation energy i...

Embodiment 2

[0033] Combining liquid-phase laser ablation technology with electrophoretic deposition method to prepare nano-tungsten oxide film, first ablate the tungsten source target by liquid-phase laser to obtain a colloidal solution containing tungsten oxide nanoparticles; Depositing on a transparent conductive glass substrate to prepare a nano-tungsten oxide film specifically includes the following steps:

[0034] Step 1, add H in the reaction vessel 2 O solution, place a 99.99% pure tungsten target in H 2 O solution, and soak the solution over the surface of the target, and stir the solution evenly with a magnetic stirrer.

[0035] Step 2. Adjust the optical path of the pulsed laser beam of the laser, so that the laser beam is focused on the target below the solvent liquid level, and a laser with a wavelength of 532nm is selected to ablate the tungsten target. The laser working frequency is 5Hz, and the laser ablation energy is 100mJ , the ablation reaction was performed on the tu...

Embodiment 3

[0040] Combining liquid-phase laser ablation technology with electrophoretic deposition method to prepare nano-tungsten oxide film, first ablate the tungsten source target by liquid-phase laser to obtain a colloidal solution containing tungsten oxide nanoparticles; Depositing on a transparent conductive glass substrate to prepare a nano-tungsten oxide film specifically includes the following steps:

[0041] Step 1, add H in the reaction vessel 2 O and H 2 o 2 A mixed solution with a volume ratio of 100:1, put a tungsten oxide target with a purity of 99.99% in the above mixed solution, soak the solution on the surface of the target, and stir the solution evenly with a magnetic stirrer.

[0042] Step 2. Adjust the optical path of the pulsed laser beam of the laser, so that the laser beam is focused on the target below the solvent liquid level, and a laser with a wavelength of 1064nm is selected to ablate the tungsten target. The laser working frequency is 10Hz, and the laser a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com