Halogen-free nano composite flame retardant and preparation method thereof

A nanocomposite and flame retardant technology, applied in the field of halogen-free nanocomposite flame retardants and its preparation, can solve the problems of poor flame retardant effect, toxic hydrogen halide gas, etc., achieve good compatibility, protect the environment, and reduce dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

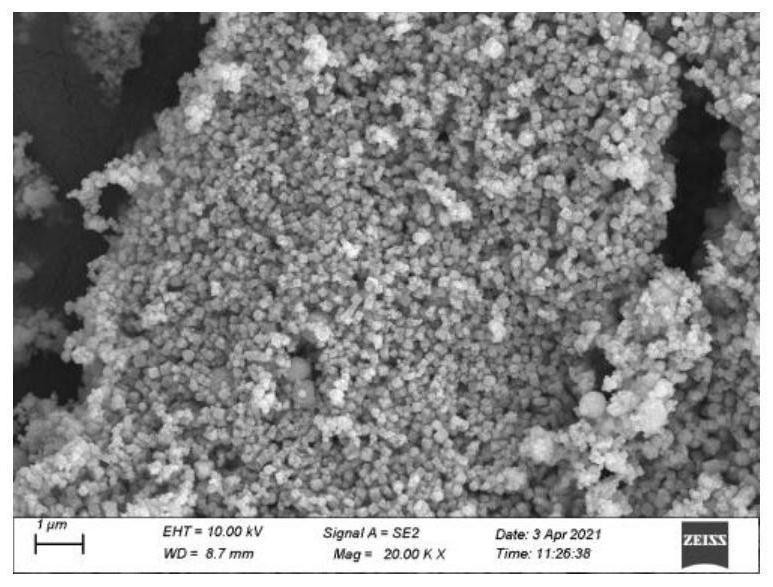

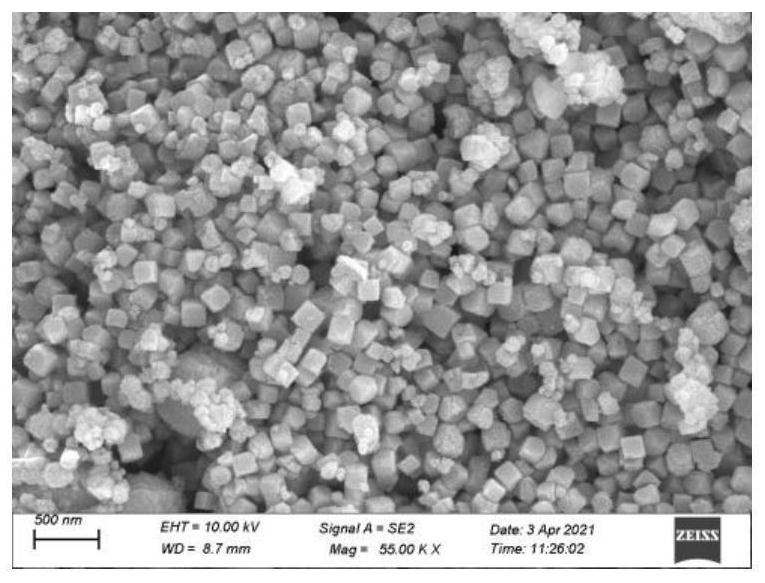

[0034] (1) Na with a molar ratio of 1:2 2 SnO 3 , ZnCl 2 Add water, stir, Na 2 SnO 3 Mixed to a concentration of 0.1mol / L, magnetically stirred for 12 hours. Then transfer the stirred emulsion to a reaction kettle, and conduct a hydrothermal reaction at 150° C. for 1 hour; obtain nano-cubes of zinc hydroxystannate;

[0035] (2) Add the nanocubes obtained in (1) to 0.05mol / L NH 4 In the F aqueous solution, the content of nanocubes is 1g / L, and the hydrothermal reaction is carried out at 150°C for 1 hour to obtain zinc hydroxystannate nanocubes with a hollow structure;

[0036] (3) Prepare 0.1mol / L MgCl 2 Aqueous solution, 1g of zinc hydroxystannate nano-cubes with hollow structure obtained in (2) was added to the above clear liquid, after stirring for 1h, added to the alkali solution with a pH value greater than 11, the Mg 2+ as Mg(OH) 2 The form of precipitation wraps on the surface of zinc hydroxystannate nanocubes with a hollow structure, forming Mg(OH) 2 |ZnSn(OH) ...

Embodiment 2

[0040] (1) Na with a molar ratio of 1:2 2 SnO 3 , ZnCl 2 Add water, stir, Na 2 SnO 3 Mixed to a concentration of 2mol / L, magnetically stirred for 12h. Then transfer the stirred emulsion to a reaction kettle, and conduct a hydrothermal reaction at 150° C. for 1 hour; obtain nano-cubes of zinc hydroxystannate;

[0041] (2) Add the nanocubes obtained in (1) to 0.5mol / L NH 4 In the F aqueous solution, the content of the nanocubes is 10g / L, and the hydrothermal reaction is carried out at 150°C for 1 hour to obtain the nanocubes of zinc hydroxystannate with a hollow structure;

[0042] (3) Prepare 1mol / L of MgCl 2 Aqueous solution, 3g of zinc hydroxystannate nano cubes with hollow structure obtained in (2) are added to the above-mentioned clear liquid, after stirring for 1h, added in the alkaline solution with a pH value greater than 11, the Mg 2+ as Mg(OH) 2 The form of precipitation wraps on the surface of zinc hydroxystannate nanocubes with a hollow structure, forming Mg(...

Embodiment 3

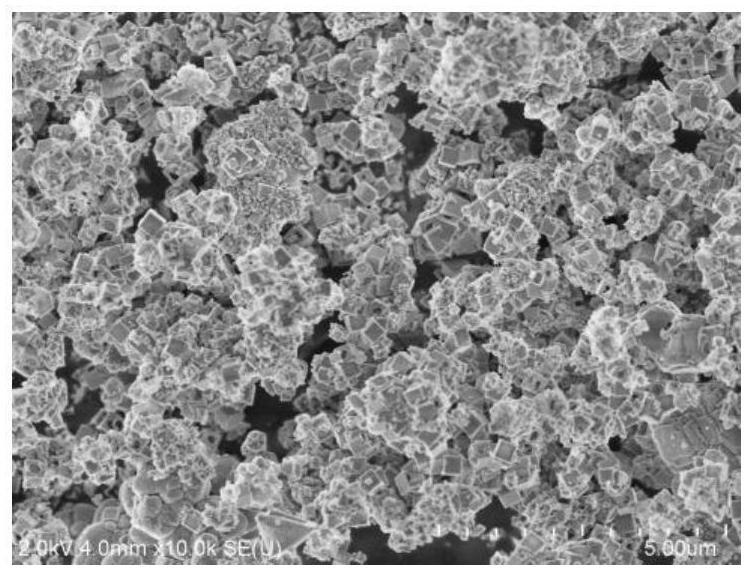

[0046] (1) Na with a molar ratio of 1:2 2 SnO 3 , ZnCl 2 Add water, stir, Na 2 SnO 3 Mixed to a concentration of 2mol / L, magnetically stirred for 12h. Then transfer the stirred emulsion to a reaction kettle, and conduct a hydrothermal reaction at 150° C. for 1 hour; obtain nano-cubes of zinc hydroxystannate;

[0047] (2) Add the nanocubes obtained in (1) to 1mol / L NH 4 In the F aqueous solution, the content of the nanocubes is 20g / L, and the hydrothermal reaction is carried out at 150°C for 1 hour to obtain the nanocubes of zinc hydroxystannate with a hollow structure;

[0048] (3) Prepare 2mol / L of MgCl 2 Aqueous solution, 5g of zinc hydroxystannate nano-cubes with hollow structure obtained in (2) is added to the above-mentioned clear liquid, after stirring for 1h, added in the alkali solution with a pH value greater than 11, the Mg 2+ as Mg(OH) 2 The form of precipitation wraps on the surface of zinc hydroxystannate nanocubes with a hollow structure, forming Mg(OH) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com