Pultrusion method of high-viscosity epoxy resin composition for carbon fibers

A technology of epoxy resin and pyridine-based epoxy resin, which is applied in the field of pultrusion molding of high-viscosity epoxy resin composition for carbon fiber, can solve problems affecting the compounding of resin and fiber interface, easy powder and peeling of products, and pulling Problems such as strong adhesion of extrusion die to achieve the effect of promoting adhesion and curing speed, increasing brittleness and increasing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-adhesive epoxy composition of carbon fiber, according to weight, including the following raw materials: bisphenol A epoxy resin, 10 parts of pyridyl epoxy resin, 40 polysiloxane polyether diols, 5 nano-filled materials, 10 under short cutting fibers, 60 active diluents, 90 anhydride curing agents;

[0031] The bisphenol A epoxy resin has 260 g / eq epoxy equivalent, a viscosity of 7500 cps, and a hydrolyzate content of less than 0.002%.

[0032] The pyridyl epoxy resin is a bipyridyl epoxy resin having a structural formula (I);

[0033] Where r is C 4 Straight alkanes -ch 2 CH 2 CH 2 CH 2 -;

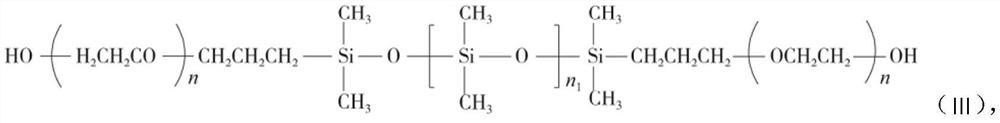

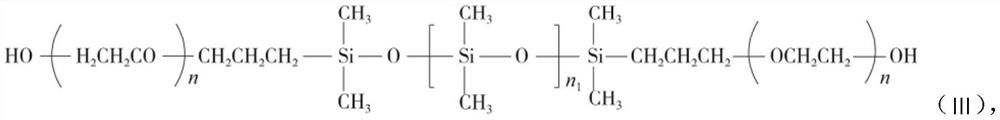

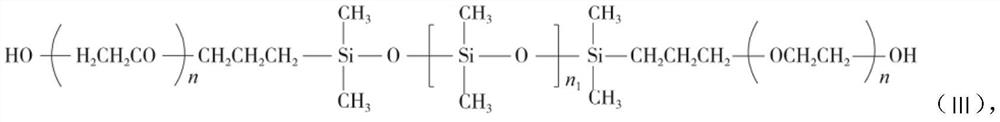

[0034] The polysiloxane polyether diol has a weight average molecular weight of 2200, with the following structural formula (III),

[0035]

[0036] Among them, N and N 1 The ratio is 1: 5;

[0037] The nano-filler is calcium carbonate, a particle diameter of 300 nm; the nanofiller is surfacely modified by an amino silicone coupling agent, a surface graft amino group of nan...

Embodiment 2

[0043] A high-adhesive epoxy resin composition for carbon fibers, according to weight, including the following raw materials: 100 parts of the bisphenol A epoxy resin, 15 parts of the pyridine epoxy resin, 30 polysiloxane polyether glycol, 3 parts of nano-filler, 10 short cuts, 40 active diluents, 80 anhydride curing agents;

[0044] The bisphenol A-type epoxy resin has 240 g / eq epoxy equivalent, viscosity of 6800 cps, and hydrolyzed chlorine content is less than 0.002%;

[0045] The pyridyl epoxy resin is a tripipyridyl epoxy resin having structural formula (II);

[0046] Where r is C 6 Linear alkane;

[0047] The polysiloxane polyether diol has a weight average molecular weight of 2400-, which has the following structural formula (III).

[0048]

[0049] Among them, N and N 1 The ratio is 1:10;

[0050] The nanofiller is a hydroxide, a particle diameter of 500 nm; the nanofer is surfacely modified by an amino silicilian coupling agent, a surface grafted amino group of nano...

Embodiment 3

[0057] A high-adhesive epoxy resin composition for carbon fibers, according to weight, including the following raw materials: bisphenol A epoxy resin, 13 parts of pyridine epoxy resin, 28 polysiloxane polyether diols, 4 parts of nano-filler, 6 short cuts, 51 active diluents, 75 nickal anhydride; the bisphenol A epoxy resin has 250 g / eq epoxy equivalent, the viscosity of 7000 cps, hydrolyzed chlorine content is less than 0.002 %.

[0058] The pyridyl epoxy resin is a structural formula (I);

[0059] Where r is C 2 Straight alkane, structure is -CH 2 CH 2 -;

[0060] The polysiloxane polyether diol has a weight average molecular weight of 2100, with the following structural formula (III),

[0061]

[0062] Among them, N and N 1 The ratio is 1.5: 10;

[0063] The nano-filler is titanium dioxide, the particle diameter is 300 nm; the nanofiller is surfacely modified by an amino silicone coupling agent, a surface grafted amino group of the nanofiller; the short cut fibers are carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com