Grouting material for repairing hollowing of exterior wall facing bricks and preparation method of grouting material

A technology for grouting and facing bricks, applied in the field of building materials, can solve the problems of high moisture content of the base layer, freeze-thaw damage of the outer wall, poor durability, etc., to improve the stability and anti-cracking performance, reduce and limit the slurry Deformation, freeze-thaw resistance and other performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

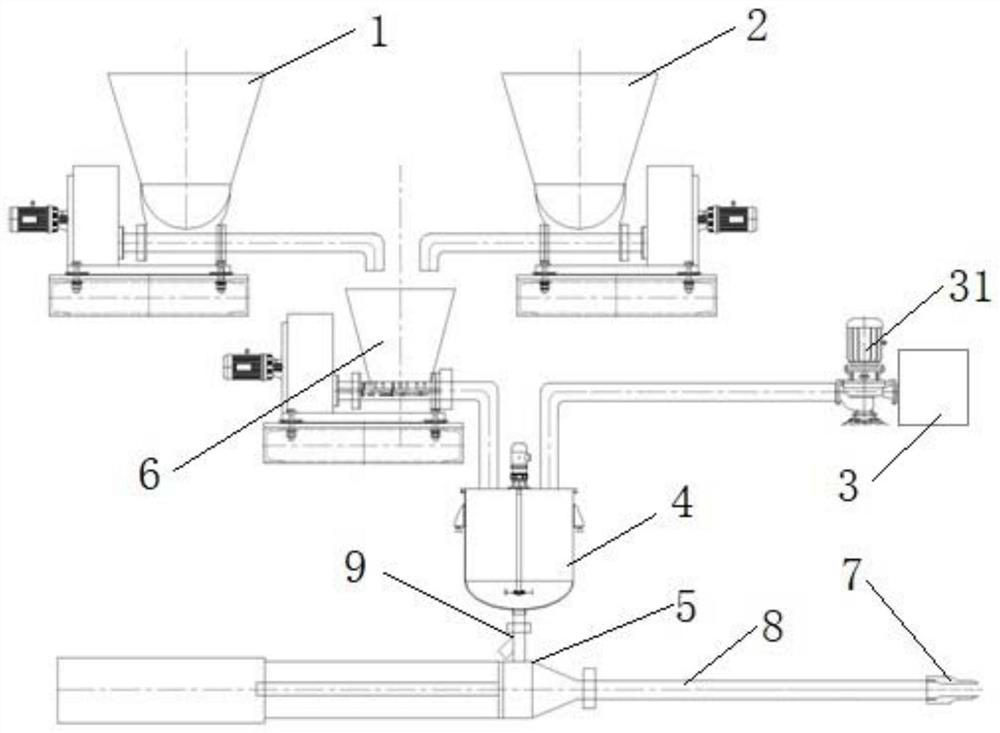

Image

Examples

Embodiment 1

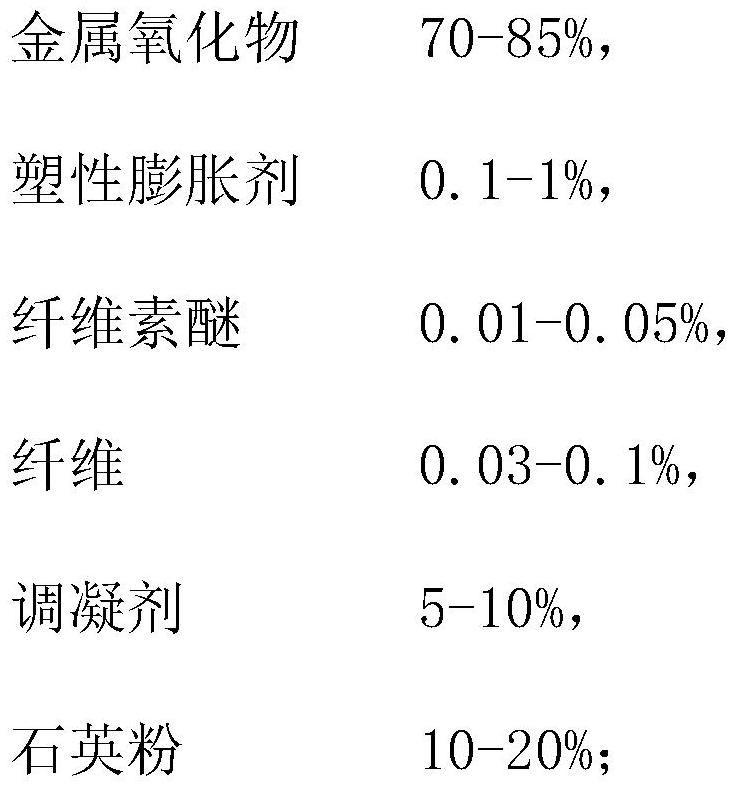

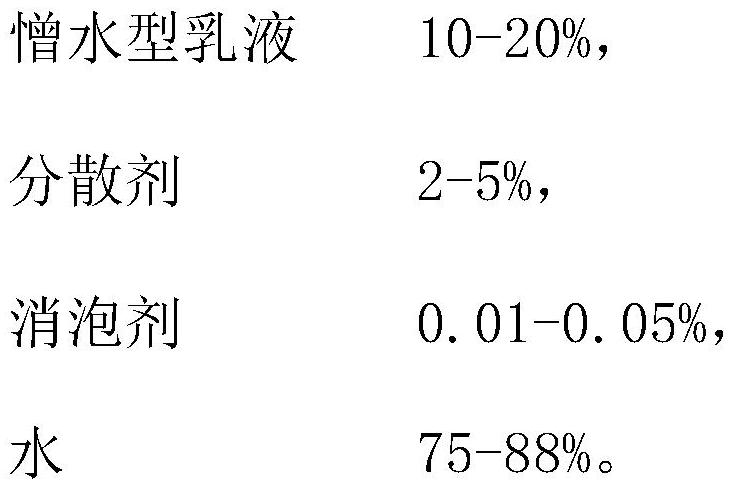

[0040] A grout for repairing hollowing of exterior wall facing bricks, which uses a three-component polymer-modified phosphate cement grout, and the three components are composed of the following raw materials in weight percentage: Component A It is composed of the following raw materials in weight percentage: 80% of magnesium oxide, 0.2% of plastic expansion agent, 0.01% of cellulose ether, 0.05% of fiber, 7% of coagulation regulator, and 12.74% of quartz powder; said component B consists of the following weight percentage Composition of raw materials: Potassium dihydrogen phosphate 13%, ammonium dihydrogen phosphate 7%, fly ash 45%, quartz sand 35%; described C component is made up of the raw material of following weight percentage: Hydrophobic emulsion 13% , dispersant 3.5%, defoamer 0.02%, water 83.48%.

[0041] A method for preparing a grout for repairing hollows of exterior wall facing bricks, comprising the following steps:

Embodiment 2

[0057] The difference from Example 1 is that the first component is made up of the following raw materials in percentage by weight: magnesia 75%, plastic expansion agent 0.2%, cellulose ether 0.02%, fiber 0.03%, coagulation regulator 7%, quartz powder 17.75% ; The B component is made up of the following raw materials in weight percentage: 13% potassium dihydrogen phosphate, 5% ammonium dihydrogen phosphate, 35% fly ash, 6% silica fume, 41% quartz sand; The components are composed of the following raw materials in weight percentage: 18% of hydrophobic emulsion, 3% of dispersant, 0.03% of defoaming agent and 78.97% of water.

[0058] When in use, stir components A, B, and C in a ratio of 1:1:0.68.

Embodiment 3

[0060] The difference from Example 1 is that the first component is made up of the following raw materials in weight percentage: 70% of magnesium oxide, 0.8% of plastic expansion agent, 0.05% of cellulose ether, 0.1% of fiber, 10% of coagulation regulator, and 19.05% of quartz powder ; The B component is made up of the following raw materials in weight percentage: potassium dihydrogen phosphate 12%, ammonium dihydrogen phosphate 3%, fly ash 60%, quartz sand 25%; the C component is composed of the following weight Raw material composition in percentage: 10% of hydrophobic emulsion, 2% of dispersant, 0.05% of defoamer, and 87.95% of water.

[0061] When in use, stir components A, B, and C in a ratio of 1:1:0.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com