Organosilicon vegetable oil-based polyol as well as preparation method and application thereof

A vegetable oil-based, organosilicon technology, which is applied in the fields of organic chemistry, chemical instruments and methods, compounds of elements of Group 4/14 of the periodic table, etc. Performance and effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

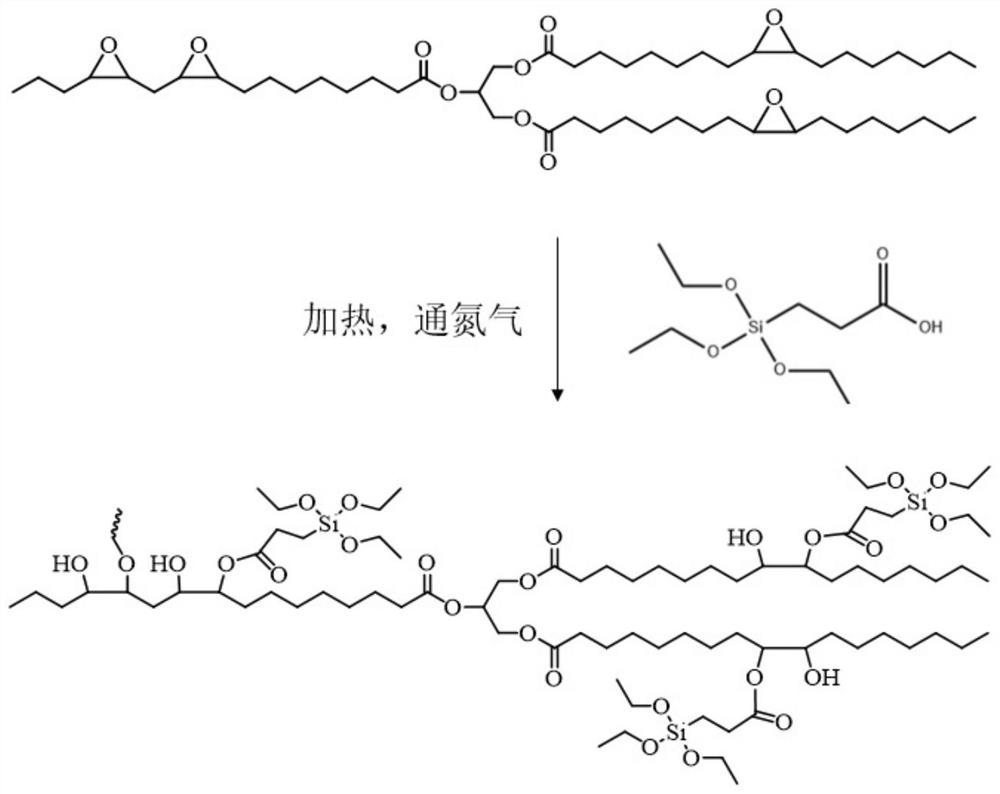

[0059] Embodiments 1-2 provide a series of organosilicon vegetable oil-based polyols, which are respectively prepared by using different carboxyl group-containing organosilicon ring-opening epoxidized soybean oil, and the specific process is as follows.

[0060] Add the carboxyl group-containing organosilicon monomer into the reaction flask, pass through nitrogen protection, then heat to 80-120°C, drop in epoxidized vegetable oil in proportion, extract the product with ethyl acetate, and use anhydrous magnesium sulfate or anhydrous Na2SO4 dried. The product was filtered and rotary evaporated to remove ethyl acetate, then dried under vacuum at 45 °C overnight to obtain a vegetable oil-based polyol with low surface energy silicone in the side chain. Concrete preparation conditions are as shown in table 2, and reaction scheme is as follows figure 1 shown.

Embodiment 3~4

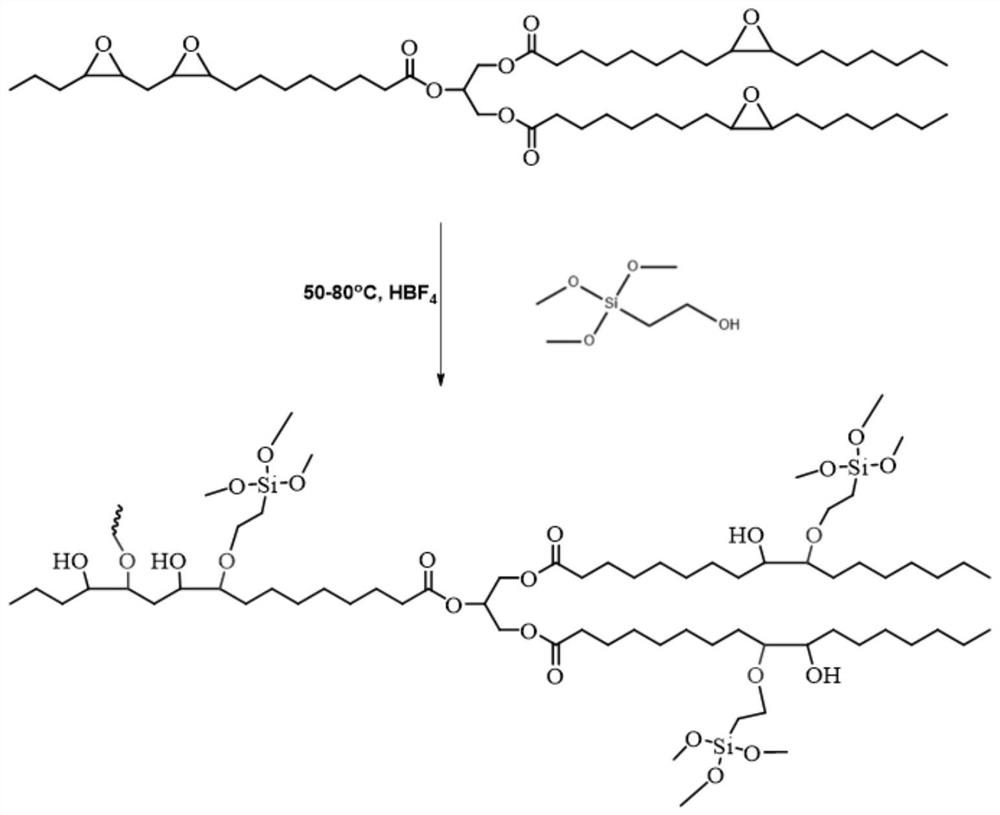

[0062] Embodiments 3-4 provide a series of organosilicon vegetable oil-based polyols, which are prepared by ring-opening reaction of epoxidized vegetable oil and hydroxyl-containing organosilicon with different structures, and the specific process is as follows.

[0063] Add the hydroxyl-containing organosilicon monomer and catalyst into the reaction flask, mix well, then heat to 40-80°C, drop in epoxidized vegetable oil in proportion, continue the reaction for 20-120min, extract the product with ethyl acetate, and use Dry over magnesium sulfate or anhydrous sodium sulfate. The product was filtered and rotary evaporated to remove ethyl acetate, then dried under vacuum at 45 °C overnight to obtain a vegetable oil-based polyol with low surface energy silicone in the side chain. Concrete reaction conditions are as shown in table 1, and reaction scheme is as follows figure 2 shown.

Embodiment 5~6

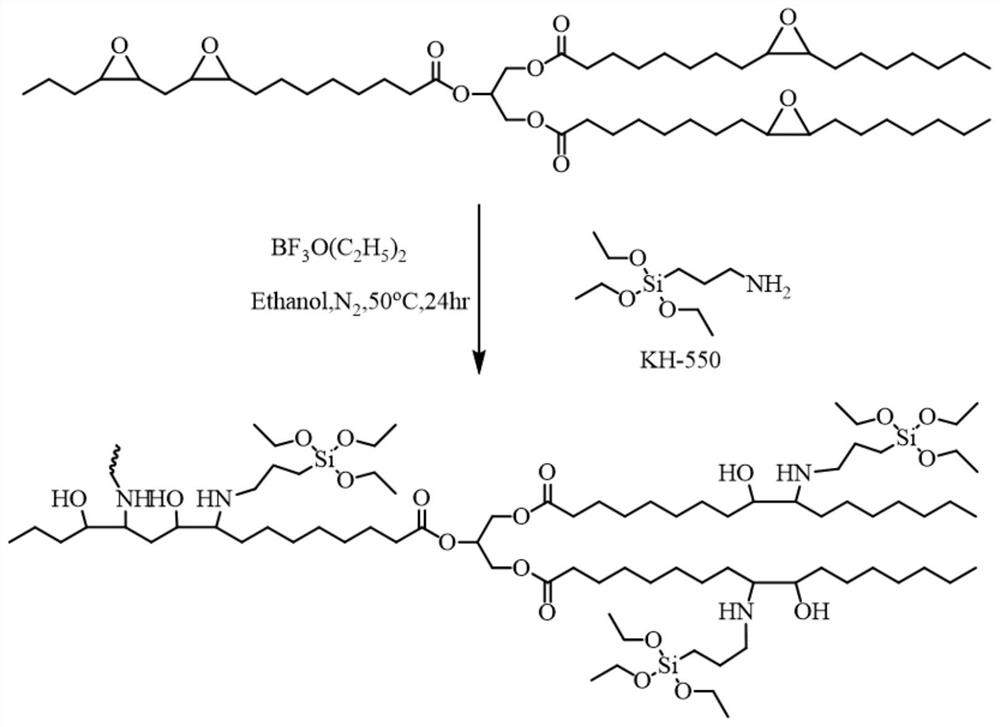

[0065] Embodiments 5-6 provide a series of silicone vegetable oil-based polyols, which are prepared by ring-opening reaction of epoxidized soybean oil and amino group-containing silicones of different structures, and the specific process is as follows.

[0066] Add hydroxyl-containing organosilicon monomers and catalysts into the reaction flask, mix well, then heat to 40-80°C, drop in epoxidized vegetable oil in proportion, and continue the reaction for 60 minutes. The product is extracted with ethyl acetate and washed with anhydrous sulfuric acid magnesium or anhydrous sodium sulfate. The product was filtered and rotary evaporated to remove ethyl acetate, then dried under vacuum at 45 °C overnight to obtain a vegetable oil-based polyol with low surface energy silicone in the side chain. The specific reaction conditions are shown in Table 1, and the reaction scheme is as follows: image 3 shown.

[0067] Characterization of Silicone Vegetable Oil Based Polyols

[0068] By t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com