Polyimide composite material, composite film and preparation methods of polyimide composite material, composite film

A technology of polyimide and composite materials, which is applied in the direction of coating, etc., can solve the problems of large calcium copper titanium oxide particles and the inability to achieve corona resistance effects, so as to improve dispersion, reduce the probability of agglomeration, and improve electrical resistance halo performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Adopt following method to prepare polyimide composite film of the present invention:

[0049] 1) Preparation of TiO 2 Nanotubes: Add titanium dioxide powder (particle size: 50 nm) and NaOH solution with a concentration of 10M in the autoclave according to the mass ratio of 1:5, seal it and put it in an oven at 140°C for 72 hours; after the reactor is cooled, put The reaction product was moved to filter paper, rinsed with 0.1M hydrochloric acid and a large amount of deionized water, and filtered for later use.

[0050] 2) In situ growth of gold nanoparticles: the rinsed and filtered TiO 2 The nanotube flocs were transferred to a suction filter with a peristaltic pump, and the titanium dioxide nanotubes were repeatedly washed with 0.01M concentration of chloroauric acid solution for 5 times; The material was moved to a 100W ultraviolet lamp and irradiated for 10-15 minutes; then the floc was naturally dried to obtain gold nanoparticle-modified titanium dioxide nanotube ...

Embodiment 2

[0064] The process for preparing the polyimide composite film is basically the same as in Example 1, the only difference being that when the polyimide composite precursor is prepared by in-situ polymerization, the titanium dioxide nanotubes modified by the gold nanoparticles modified by the silane coupling agent account for 1% of the total. 15% of the total mass of all dianhydride and diamine precursors.

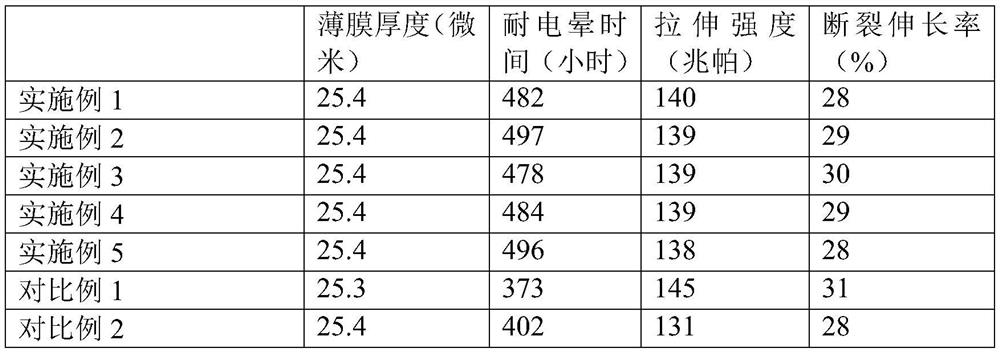

[0065] The performance of the composite film was also tested, and the results are shown in Table 1.

Embodiment 3

[0067] The process for preparing the polyimide composite film is basically the same as in Example 1, the only difference being that when the polyimide composite precursor is prepared by in-situ polymerization, the titanium dioxide nanotubes modified by the gold nanoparticles modified by the silane coupling agent account for 1% of the total. 20% of the total mass of all dianhydride and diamine precursors.

[0068] The performance of the composite film was also tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com