Self-supporting porous dendritic graphite foam, and preparation method and application thereof

A graphite foam and dendritic technology, which is applied to electrodes and preparation fields with tip charge aggregation effect, can solve the problems of high chlorine content, excessive amount of bleaching powder added, insufficient sterilization effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

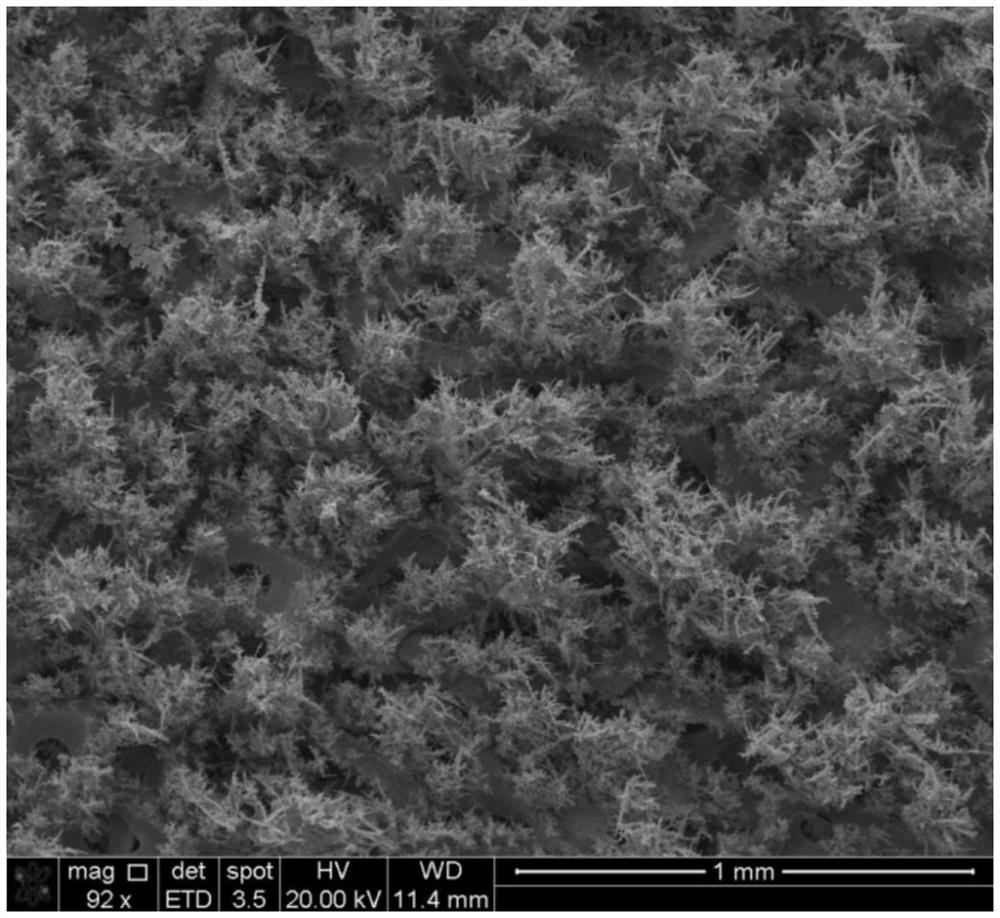

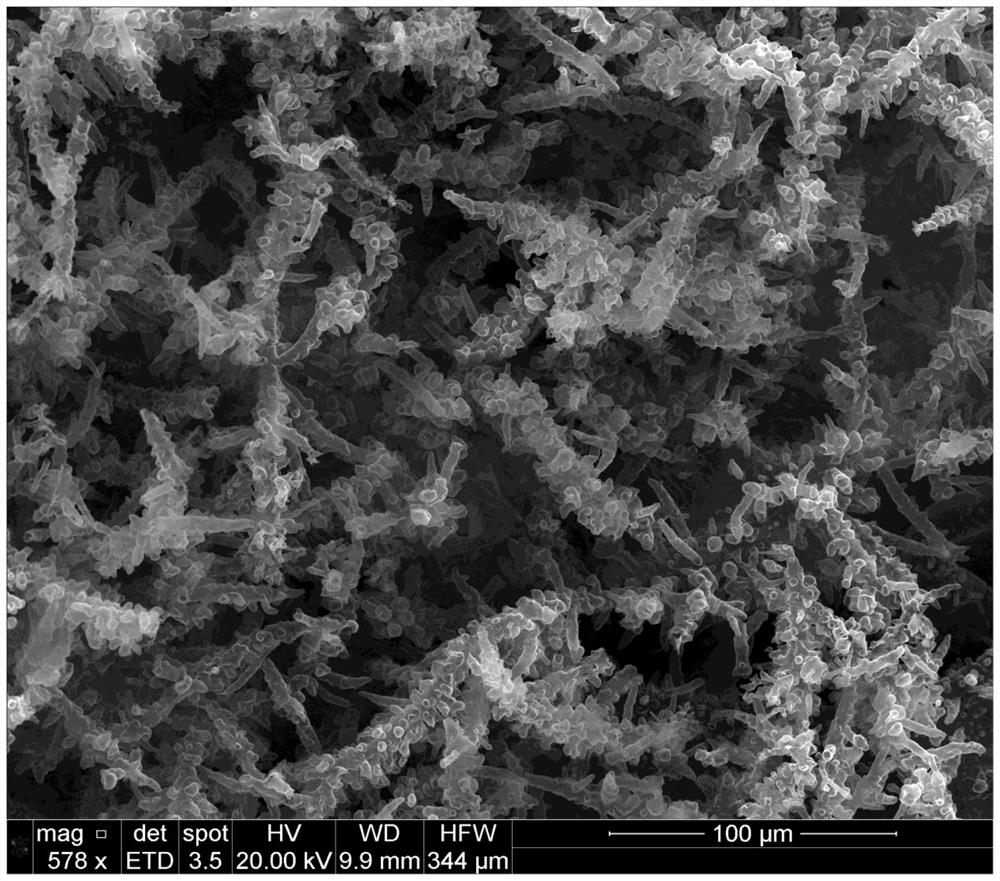

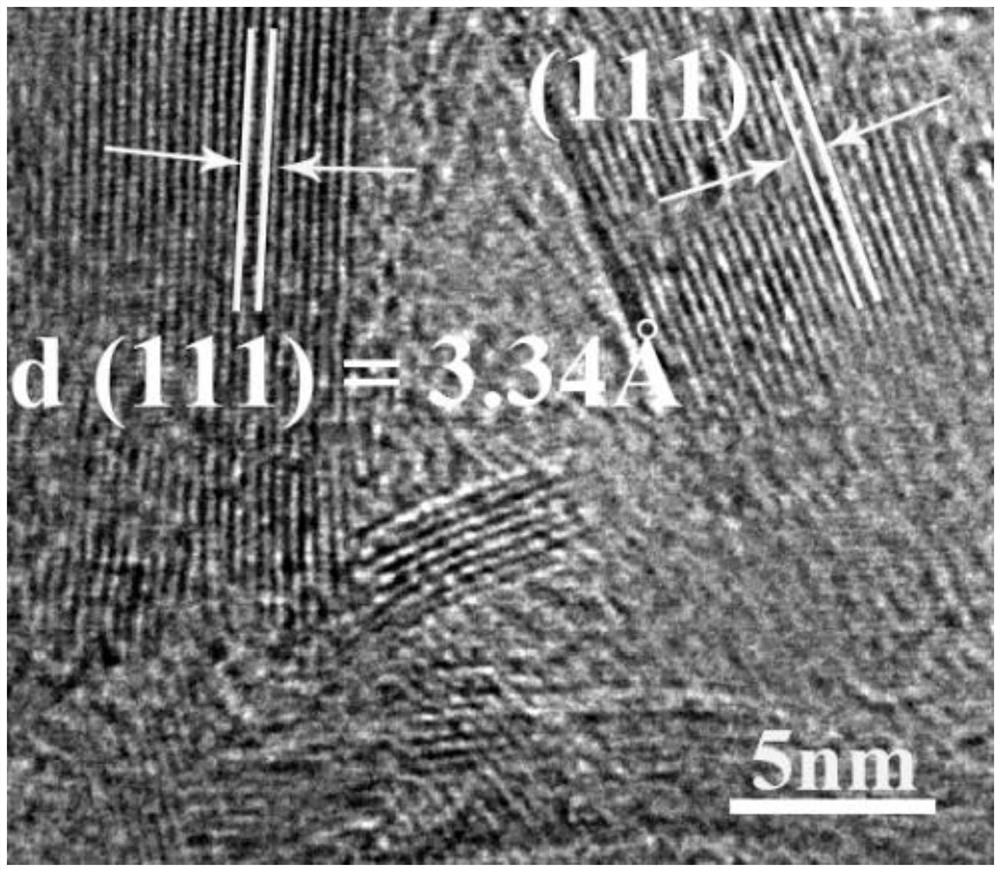

[0024] A preparation method of self-supporting porous dendritic graphite foam, carried out in the following steps:

[0025] Step 1. Press the nickel foam substrate into a thin sheet with a thickness of 100 μm by a double-roller press to obtain sheet-shaped nickel foam, and then wash the foam with acetone, sulfuric acid and deionized water in order to remove the oxide layer on the surface for subsequent use. The pore diameter of the nickel foam substrate is 250 μm, and the thickness is 1mm;

[0026] Step 2, mixing copper sulfate, nickel chloride and boric acid to form an electrolyte, the concentration of copper sulfate in the electrolyte is 0.0001M, the concentration of nickel chloride is 0.1M, and the concentration of boric acid is 0.1M;

[0027] Put nickel foam in the electrolyte, and then grow Ni-Cu alloy dendritic branches on the three-dimensional porous framework of nickel foam by electrochemical deposition to obtain metal semi-finished products;

[0028] Electrochemical ...

Embodiment 2

[0036] A preparation method of self-supporting porous dendritic graphite foam, carried out in the following steps:

[0037] Step 1. Press the nickel foam substrate into a thin sheet with a thickness of 300 μm by a double-roller press to obtain sheet-shaped nickel foam, and then wash the foam with acetone, sulfuric acid and deionized water in order to remove the oxide layer on the surface for subsequent use. The aperture of the nickel foam substrate is 250 μm, the thickness is 3mm, the length is 50mm, and the width is 40mm;

[0038] Step 2, mixing copper sulfate, nickel chloride and boric acid to form an electrolyte, the concentration of copper sulfate in the electrolyte is 0.01M, the concentration of nickel chloride is 1M, and the concentration of boric acid is 1M;

[0039] Put nickel foam in the electrolyte, and then grow Ni-Cu alloy dendritic branches on the three-dimensional porous framework of nickel foam by electrochemical deposition to obtain metal semi-finished products...

Embodiment 3

[0050] Arrange 16 parallel electrodes in the test box, the edge of each electrode is connected through copper foil, the connection method is AC / ground / AC / ground..., and so on, such as Figure 5Shown; Electrode adopts the self-supporting porous dendritic graphite foam that embodiment 2 makes ②, injects raw water in square box, and raw water contains initial concentration and is 10 6 Escherichia coli in CFU / mL (colony / milliliter), raw water volume 100mL;

[0051] Set up multiple groups of sterilization experiments respectively. After the experiment, take samples to measure the end concentration of Escherichia coli, and calculate the sterilization efficiency. The sterilization efficiency = (initial concentration - end concentration) / initial concentration * 100%. The sterilization efficiency of each group is shown below surface:

[0052] Voltage frequency duration Bacteria removal efficiency 1 0.5V 1×10Hz 20min 92.910% 2 4V 1×10Hz 20min 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com