Laser surface heat treatment method for high-entropy alloy with reverse gradient nanostructure

A surface heat treatment and high-entropy alloy technology, which is applied in the field of high-entropy alloy preparation and processing, can solve the problems of enhancing the mutation-induced strengthening and work hardening effects of high-entropy alloys, and the inability to have both strength and plasticity of high-entropy alloys. Effects of thermal stress, enhanced mutation-induced strengthening and work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

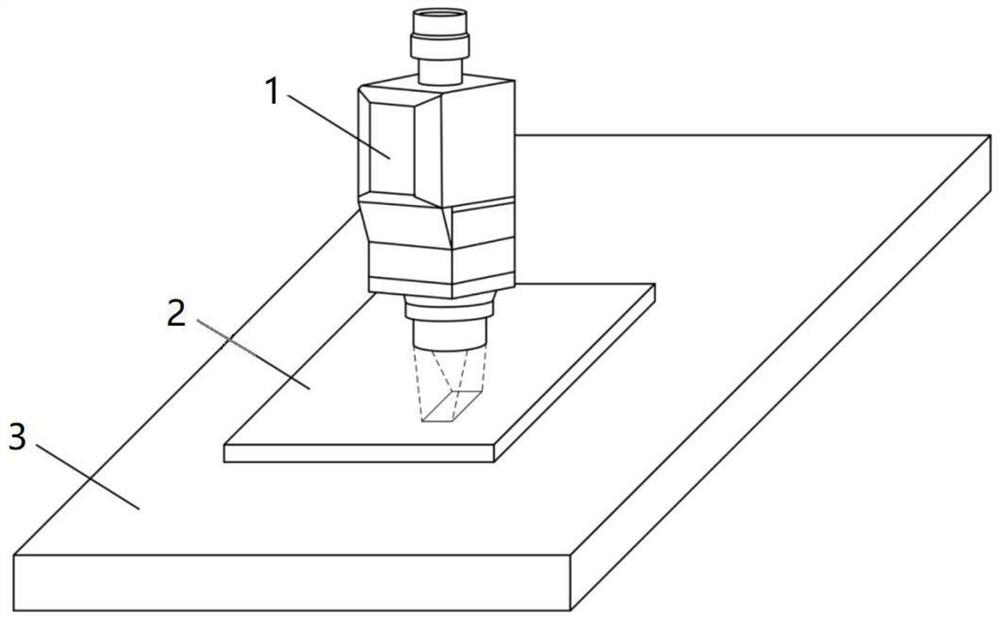

Image

Examples

Embodiment 1

[0032] (1) Using pure metal with a purity ≥ 99.7wt.% as a raw material, a CoCrFeMnNi high-entropy alloy ingot was prepared by a vacuum induction melting process, and smelted repeatedly 5 times to ensure the uniformity of the chemical composition of the high-entropy alloy ingot;

[0033] (2) Heating the CoCrFeMnNi high-entropy alloy ingot to 1200°C and keeping it warm for 180min, then performing hot forging after being out of the furnace, the hot forging temperature is controlled at 1100°C, and the final forging thickness is controlled at 30mm;

[0034] (3) The high-entropy alloy forging blank needs to be annealed before cold rolling. The annealing temperature is 1000°C, the annealing time is 1h, and the annealing cooling method is water cooling;

[0035] (4) The high-entropy alloy forging billet after the annealing heat treatment is rolled at room temperature, the pass reduction is 0.3-2.5 mm, the total reduction rate is 88.3%, and the final rolling thickness is 3.5 mm;

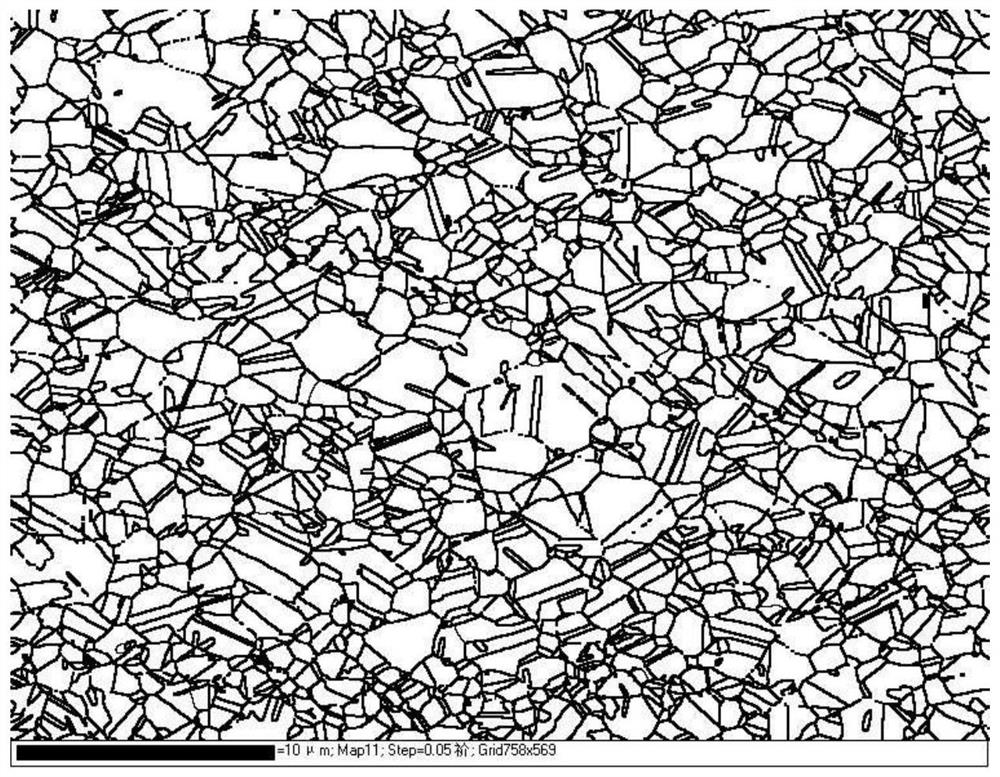

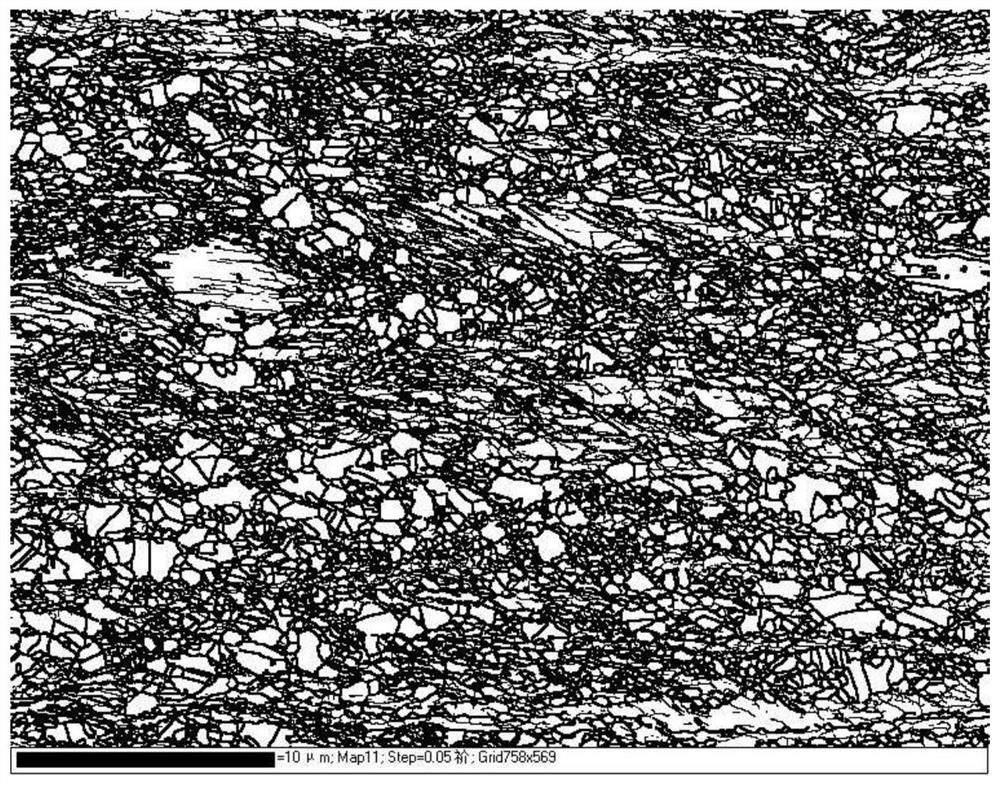

[003...

Embodiment 2

[0039] (1) Using pure metal with a purity ≥ 99.7wt.% as a raw material, a CoCrFeMnNi high-entropy alloy ingot was prepared by a vacuum induction melting process, and smelted repeatedly 3 times to ensure the uniformity of the chemical composition of the high-entropy alloy ingot;

[0040] (2) Heat the CoCrFeMnNi high-entropy alloy ingot to 1250°C and keep it warm for 120min, then perform hot forging after it comes out of the furnace, the hot forging temperature is controlled at 1150°C, and the final forging thickness is controlled at 22mm;

[0041] (3) The high-entropy alloy forging billet needs to be annealed before cold rolling. The annealing temperature is 1000℃, the annealing time is 2h, and the annealing cooling method is water cooling;

[0042](4) The high-entropy alloy forging billet after the annealing heat treatment is rolled at room temperature, the pass reduction is 0.3-2.5mm, the total reduction rate is 86.4%, and the final rolling thickness is 3mm;

[0043] (5) Use ...

Embodiment 3

[0046] (1) Using pure metal with a purity ≥ 99.7wt.% as a raw material, a CoCrFeMnNi high-entropy alloy ingot was prepared by a vacuum induction melting process, and smelted repeatedly 4 times to ensure the uniformity of the chemical composition of the high-entropy alloy ingot;

[0047] (2) Heat the CoCrFeMnNi high-entropy alloy ingot to 1200°C and keep it warm for 240min, then perform hot forging after it comes out of the furnace, the hot forging temperature is controlled at 1100°C, and the final forging thickness is controlled at 27mm;

[0048] (3) The high-entropy alloy forging blank needs to be annealed before cold rolling. The annealing temperature is 900°C, the annealing time is 5 hours, and the annealing cooling method is water cooling;

[0049] (4) The high-entropy alloy forging billet after the annealing heat treatment is rolled at room temperature, the pass reduction is 0.3-2.5 mm, the total reduction rate is 88.3%, and the final rolling thickness is 4.5 mm;

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com