Sample preparation method for hot-rolled strip steel oxide scale EBSD analysis

A technology for hot-rolled strip steel and iron oxide scale, applied in the field of steel rolling, can solve the problems of difficult sample preparation and detection, high cost, etc., and achieves the effects of high universality, low cost, and poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of sample preparation method of EBSD analysis of hot-rolled steel strip scale, carries out according to the following operation steps:

[0030] Step 1: Use SPHC hot-rolled strip steel, and use a wire cutting machine to cut out a test sample with a size of 10*8*2mm. After cutting, use ultrasonic waves to clean in absolute ethanol for 10 minutes;

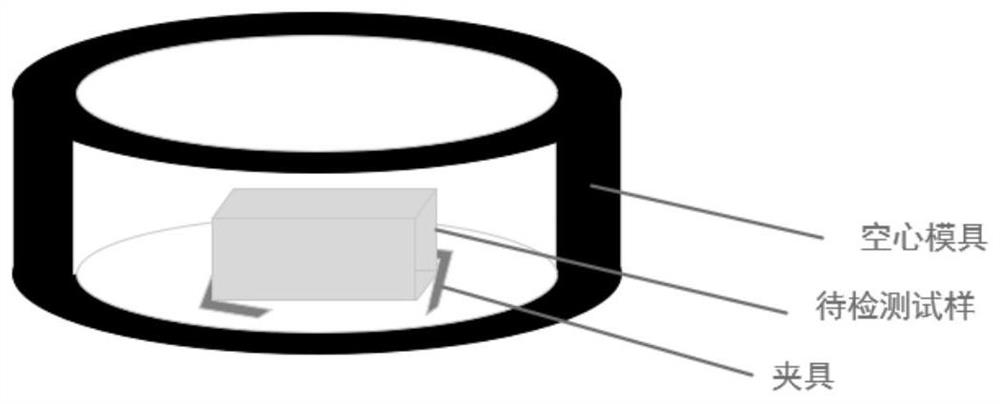

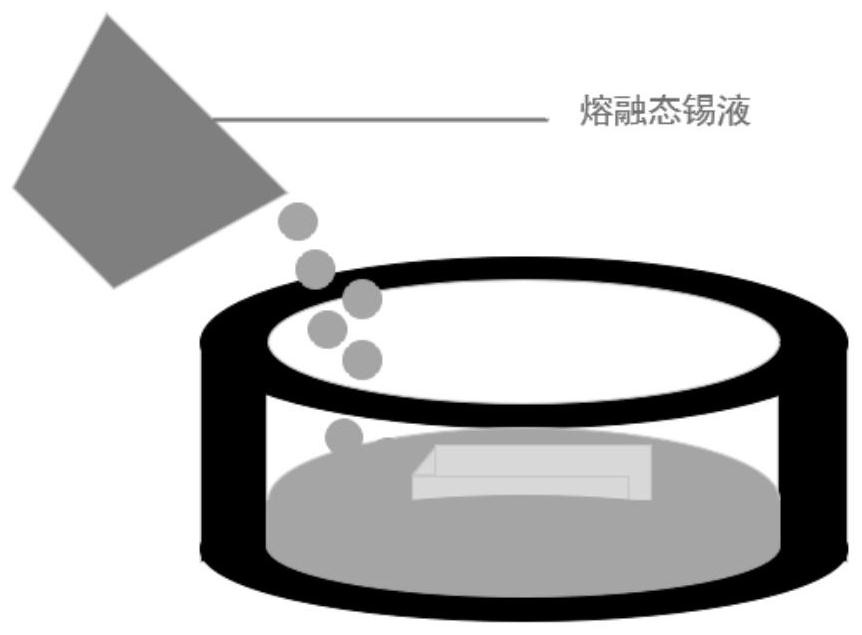

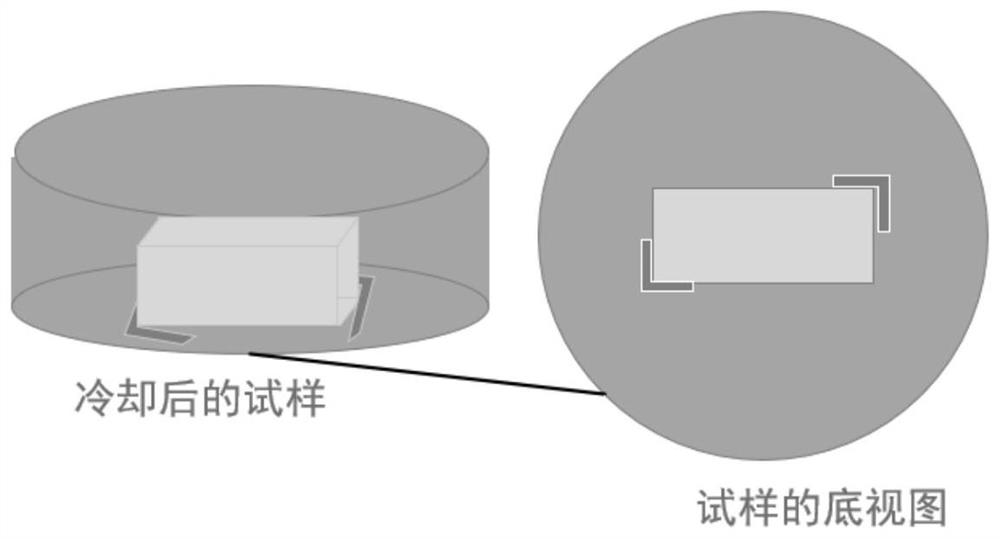

[0031] Step 2: If figure 1 , the sample is fixed with a metal fixture and placed in a corundum mold, the tin block is melted in a crucible, and slowly poured into the mold after it is in a molten state, as figure 2 As shown; the amount of pouring of molten tin liquid completely covers the sample; after the mold is naturally cooled to room temperature, it is demolded to obtain a cast sample;

[0032] Step 3: For cast samples, follow image 3 Use 1000, 1200, 1500# sandpaper to perform unidirectional grinding along the direction of the scale, and then use a polishing machine to mechanically polish the sample. The partic...

Embodiment 2

[0043] A sample preparation detection method for hot-rolled strip steel oxide scale EBSD analysis is carried out according to the following steps:

[0044] Step 1: Use Q235 hot-rolled steel strip, and use a wire cutting machine to cut out a test sample with a size of 8*8*2mm. After cutting, use ultrasonic waves to clean in absolute ethanol for 10 minutes;

[0045]Step 2: Fix the cleaned sample with a metal fixture and place it in the corundum mold, put the tin block into the crucible to melt, and slowly pour it into the mold and cover the sample after it is in a molten state; wait for the mold to naturally After cooling to room temperature, demoulding is carried out to obtain a cast sample;

[0046] Step 3: Use 1200 and 1500# sandpaper in sequence to grind the cast sample in one direction along the scale direction, and then use a polishing machine to mechanically polish the sample. The particle size of the diamond polishing paste is selected to be 1.5 μm, mechanically polishe...

Embodiment 3

[0050] A sample preparation detection method for hot-rolled strip steel oxide scale EBSD analysis is carried out according to the following steps:

[0051] Step 1: Use Q235 hot-rolled steel strip, and use a wire cutting machine to cut out a test sample with a size of 8*6*3mm. After cutting, use ultrasonic waves to clean in absolute ethanol for 12 minutes;

[0052] Step 2: Fix the cleaned sample with a metal fixture and place it in the corundum mold, put the tin block into the crucible to melt, and slowly pour it into the mold and cover the sample after it is in a molten state; wait for the mold to naturally After cooling to room temperature, demoulding is carried out to obtain a cast sample;

[0053] Step 3: Use 1200 and 1500# sandpaper in sequence to grind the cast sample in one direction along the scale direction, and then use a polishing machine to mechanically polish the sample. The particle size of the diamond polishing paste is 2.5 μm, mechanically polished for 60 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com