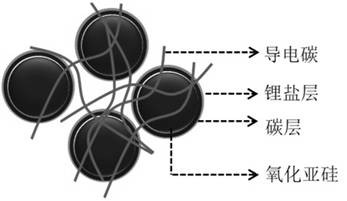

A kind of lithium-ion battery high-capacity silicon oxide composite negative electrode material and preparation method thereof

A silicon oxide and negative electrode material technology, applied in battery electrodes, electrode manufacturing, non-aqueous electrolyte battery electrodes, etc., can solve the problem that the Coulombic efficiency is less than 70%, achieve improved cycle stability, good application prospects, and improve the first effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the lithium-ion battery high-capacity silicon oxide composite negative electrode material of this embodiment is as follows:

[0035] (1) Dissolve a certain amount of chitosan in deionized water, stir magnetically for 2 hours, add hydrochloric acid, adjust the pH to 2, continue magnetically stirring for 2 hours, then add silicon oxide according to 10 times the mass of chitosan, and stir magnetically. Slurry A was obtained after ultrasonic and ball milling;

[0036] (2) Spray-drying and calcining the slurry A to obtain a carbon-coated silicon oxide material. The spray-drying conditions are as follows: inlet temperature is 180°C, outlet temperature is 90°C, calcination conditions are protective gas, low temperature 200°C, heat preservation 1h, high temperature 750°C, heat preservation 2.5h, and the heating rate is 5°C / min;

[0037] (3) The above-mentioned carbon-coated silicon oxide material, carbon nanotubes, and lithium carbonate were mixed in ...

Embodiment 2

[0045] The preparation method of the lithium-ion battery high-capacity silicon oxide composite negative electrode material of this embodiment is as follows:

[0046] (1) Dissolve a certain amount of chitosan in deionized water, stir magnetically for 2 hours, add acetic acid to adjust the pH to 3, continue magnetically stirring for 2 hours, then add silicon oxide according to 13 times the mass of chitosan, and stir magnetically. Slurry A was obtained after ultrasonic and ball milling;

[0047] (2) Spray-drying and calcining the slurry A to obtain a carbon-coated silicon oxide material. The spray drying conditions are as follows: inlet temperature is 195°C, outlet temperature is 85°C, calcination conditions are protective gas, low temperature 250°C, heat preservation for 0.5h, high temperature 650°C, heat preservation for 4 hours, and the heating rate is 5°C / min;

[0048] (3) The above-mentioned carbon-coated silicon oxide material, graphene, and lithium hydroxide were mixed in a...

Embodiment 3

[0052] The preparation method of the lithium-ion battery high-capacity silicon oxide composite negative electrode material of this embodiment is as follows:

[0053] (1) Dissolve a certain amount of chitosan in deionized water, stir magnetically for 2 hours, add sulfuric acid, adjust the pH to 4, continue magnetically stirring for 2 hours, then add silicon oxide according to 8 times the mass of chitosan, and stir magnetically. Slurry A was obtained after ultrasonic and ball milling;

[0054] (2) Spray-drying and calcining the slurry A to obtain a carbon-coated silicon oxide material. The spray drying conditions are as follows: inlet temperature is 190°C, outlet temperature is 95°C, calcination conditions are protective gas, low temperature 150°C, heat preservation for 2 hours, high temperature 800°C, heat preservation for 2.5 hours, and the heating rate is 5°C / min;

[0055] (3) Mix the above-mentioned carbon-coated silicon oxide material, carbon nanofibers, and lithium oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com