A coating modification method for preparing high-temperature lithium-ion battery lithium manganate cathode material

A positive electrode material and modification technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of large thickness of coating layer, poor bonding force between coating layer material and lithium manganese oxide, poor cycle performance and rate performance of materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

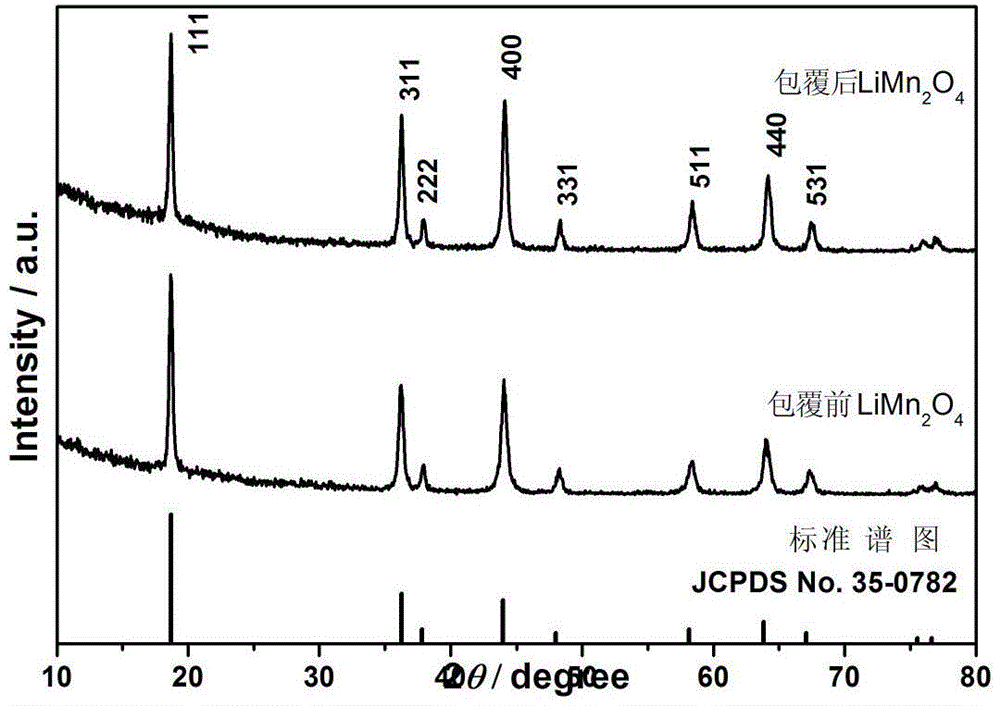

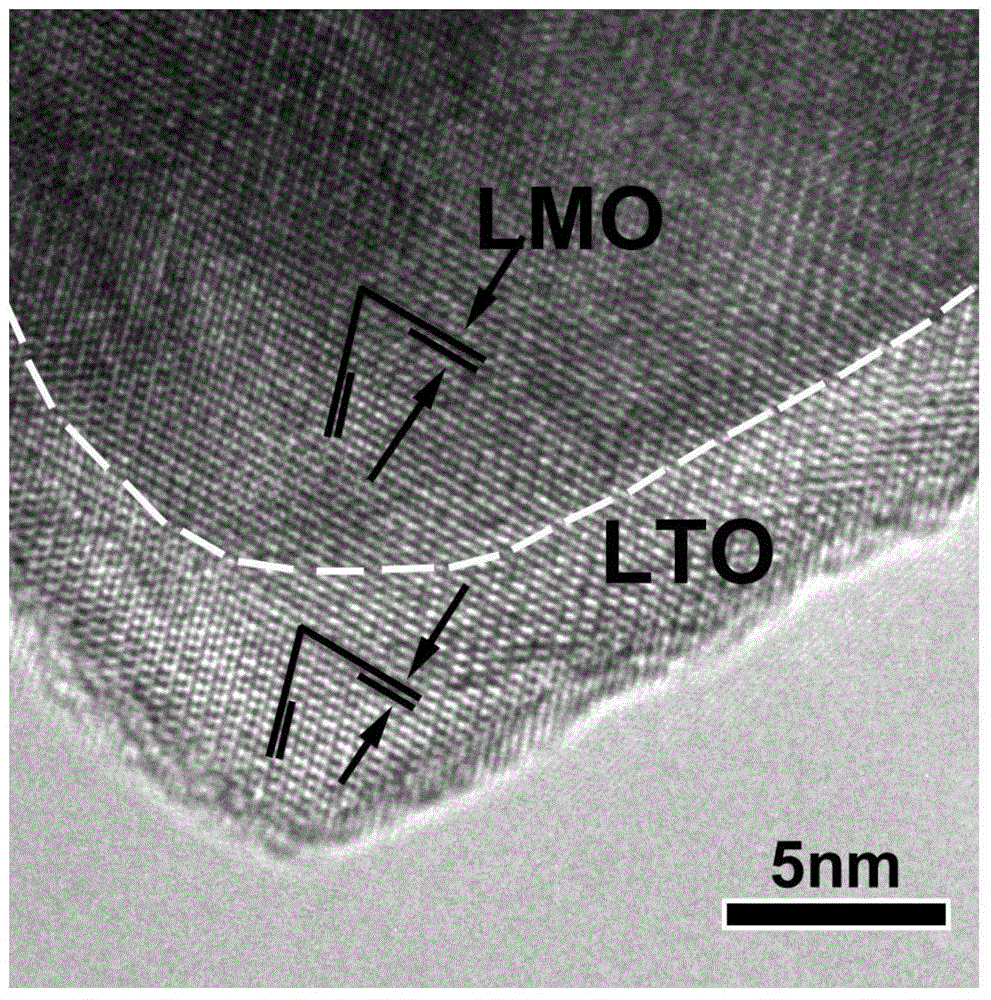

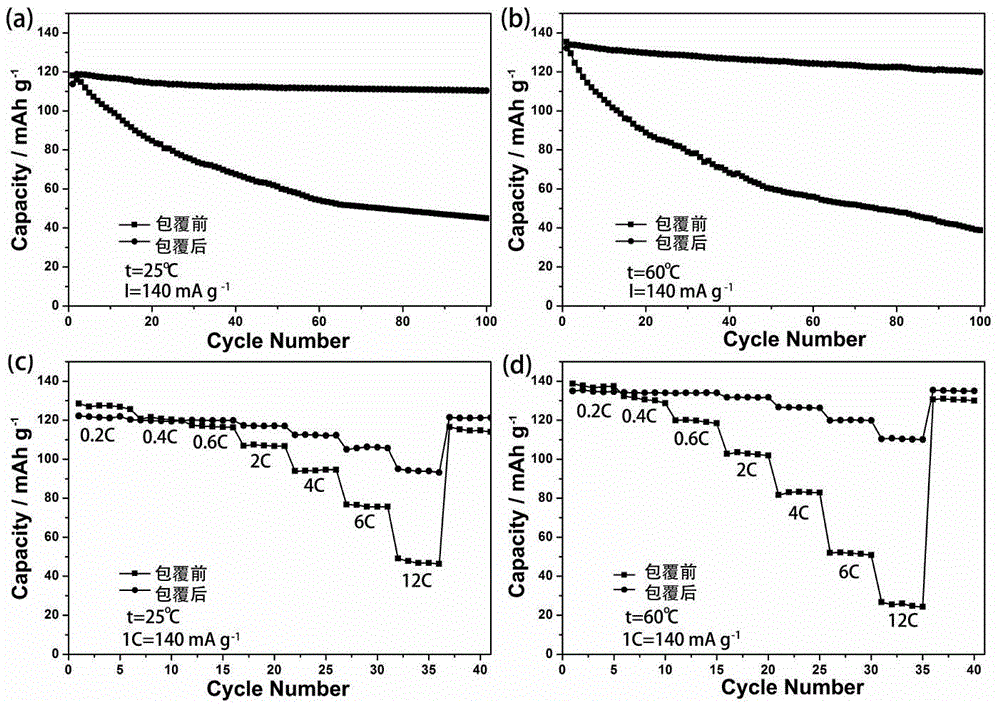

[0024] Add the ethanol solution of tetrabutyl titanate to LiMn 2 O 4 In the ethanol suspension (of which LiMn 2 O 4 The mass ratio to tetrabutyl titanate is 10:1), and continue to stir for 20 minutes. Then, it was transferred to a hydrothermal reaction kettle and kept at 150°C for 5 hours. After cooling to room temperature, the precipitate was filtered and washed several times to obtain an amorphous titanium oxide-coated lithium manganate precursor; The body is fully mixed with a certain amount of lithium hydroxide in ethanol solution, dried at 80°C, and after grinding, treated in an air atmosphere at 700°C in a high-temperature furnace for 12 hours to obtain Li 4 Ti 5 O 12 Coated modified LiMn 2 O 4 Cathode material. figure 1 It is an X-ray diffraction pattern, the analysis of the modified material does not affect the main material LiMn 2 O 4 Spinel structure. figure 2 Is Li 4 Ti 5 O 12 Coated modified LiMn 2 O 4 Photo of cathode material, showing Li 4 Ti 5 O 12 The coating is ...

Embodiment example 2

[0027] Add the ethylene glycol solution of tetrabutyl titanate to LiMn 2 O 4 Ethylene glycol suspension (of which LiMn 2 O 4 The mass ratio to tetrabutyl titanate is 10:1), and continue to stir for 20 minutes. Then, it was transferred to a hydrothermal reactor and kept at 120°C for 15 hours. After cooling to room temperature, the precipitate was filtered and washed several times to obtain an amorphous titanium oxide-coated lithium manganate precursor; The body is thoroughly mixed with a certain amount of lithium nitrate in methanol solution, dried at 80°C, and after grinding, treated in an air atmosphere at 750°C in a high-temperature furnace for 10 hours to obtain Li 4 Ti 5 O 12 Coated modified LiMn 2 O 4 Cathode material.

Embodiment example 3

[0029] Add the ethanol solution of tetrabutyl titanate to LiMn 2 O 4 In the ethanol suspension (of which LiMn 2 O 4 The mass ratio to tetrabutyl titanate is 15:1), continue to stir for 20 minutes. Then, it was transferred to a hydrothermal reactor and kept at 200°C for 2 hours. After cooling to room temperature, the precipitate was filtered and washed several times to obtain an amorphous titanium oxide-coated lithium manganate precursor; The body is thoroughly mixed with a certain amount of lithium acetate in ethylene glycol solution, dried at 120°C, and after grinding, treated in an air atmosphere at 800°C in a high-temperature furnace for 5 hours to obtain Li 4 Ti 5 O 12 Coated modified LiMn 2 O 4 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com