High-entropy perovskite membrane and application in oxygen separation and membrane reactor

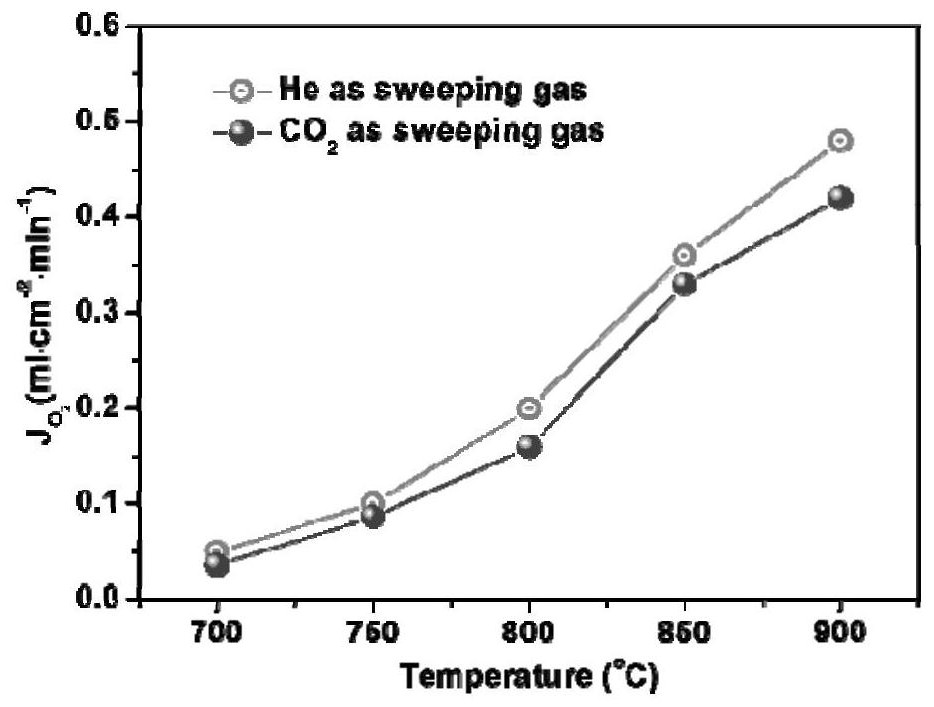

A perovskite, high-entropy technology, used in semi-permeable membrane separation, separation methods, dispersed particle separation, etc., can solve the problem of low metal ion diffusion rate, unsatisfactory oxygen permeability performance and stability, and hinder mixed conductor oxygen permeation membrane. Technical application and other issues, to achieve the effect of reducing the diffusion rate of metal ions, promoting the formation of fast oxygen ions and electron channels, excellent oxygen permeability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

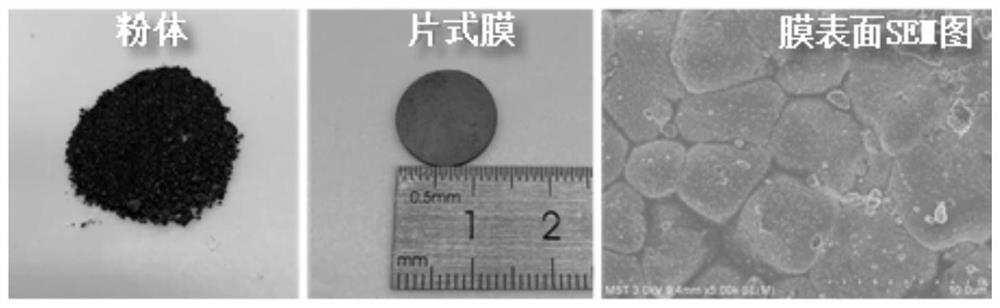

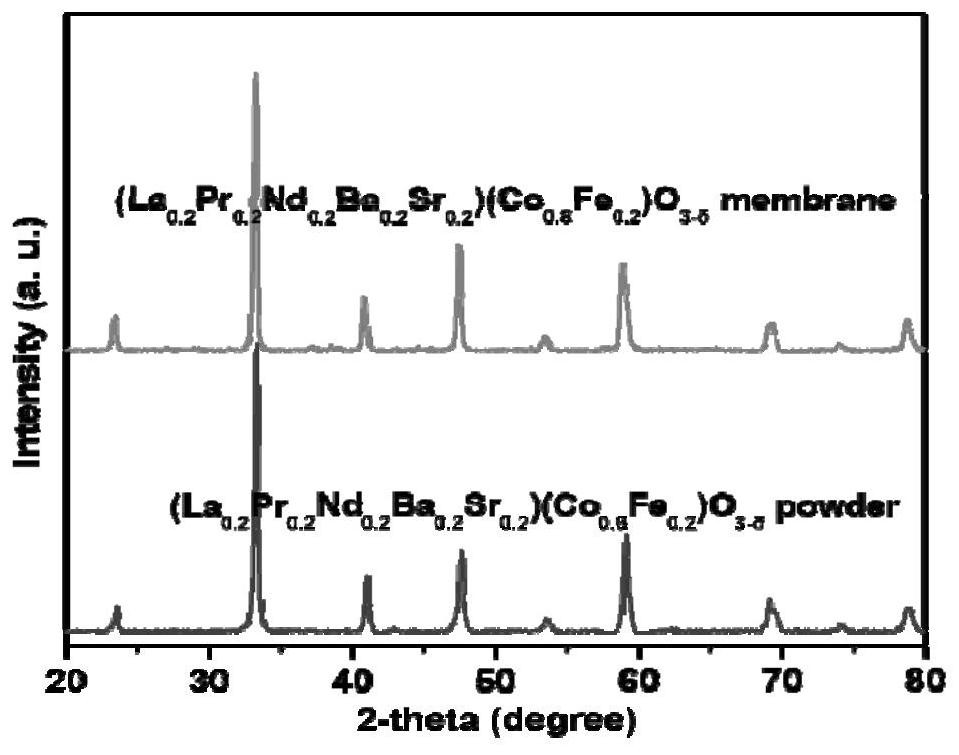

[0035] Preparation of the invention (LA) with solid phase reaction method (LA 0.2 PR 0.2 ND 0.2 BA 0.2 SR 0.2 (Co) 0.8 FE 0.2 ) O 3-δ Take a sample, the chemical measurement of materials will be purchased by LA (CO) 3 ) 3 PR 2 (Co 3 ) 3 ND 2 O 3 , Baco 3 , SRCO 3 , CO 2 O 3 , Fe 2 O 3 After the powder was precisely mixed, anhydrous ethanol was added, placed in a ball mill, wet grinding 8h, and the rotational speed was 500 rpm. The mixture after wet milling was placed in an oven, and the dried powder was placed in a high temperature muffle furnace, and the particle diameter was calcined in a 950 ° C air atmosphere. After grinding, the particle size was about 800 nm (LA) 0.2 PR 0.2 ND 0.2 BA 0.2 SR 0.2 (Co) 0.8 FE 0.2 ) O 3-δ Pre-generic powder.

[0036] The powder was pressed into a membrane green body by a stainless steel mold having an inner diameter of 14 mm, and the heating rate was controlled at 1 ° C / min, and the film green body was tied to room temperature at a rate of 1.5...

Embodiment 2

[0041] Preparation of a material (LAPRCABASR) by solid phase reaction method 0.2 (Co 0.8 FE 0.2 ) O 3-δ Take a sample, the chemical measurement of materials will be purchased by LA (CO) 3 ) 3 PR 2 (Co 3 ) 3 Caco 3 , Baco 3 , SRCO 3 , CO 2 O 3 , Fe 2 O 3 After the powder is exactly mixed, anhydrous ethanol is added, placed in a ball mill, and the rotational speed is 550 rpm, and then dried in a static air, and the dried powder is placed in a high temperature muffle, calcined in an air atmosphere at 1000 ° C for 8 h After grinding, the particle size is approximately 2 μm (LAPRCABASR) 0.2 (Co 0.8 FE 0.2 ) O 3-δ Pre-generic powder.

[0042] The powder was pressed into a film green body under 18 mPa pressure by a stainless steel mold having an inner diameter of 14 mm, and the heating rate was controlled to 3 ° C / min, and the film green body was sintered at 1250 ° C for 10 h, and the rate of 3 ° C / min was lowered to room temperature, That is, the slice film (the thickness of the fil...

Embodiment 3

[0046] Preparation of a material (LAPRCABASR) by solid phase reaction method 0.2 (CoCrfemnni) 0.2 O 3-δ Take an example, the chemical measurement of materials will be purchased by LA (CO) 3 ) 3 PR 2 (Co 3 ) 3 Caco 3 , Baco 3 , SRCO 3 , CO 2 O 3 , Cr 2 O 3 , Fe 2 O 3 After the MnO, NiO powder is precisely mixed, anhydrous ethanol is added, placed in a ball mill 12h, rotation speed of 600 rpm, and then dried in static air, put the dry powder into a high temperature muffle, at 1250 ° C Calcination of 7 h in the air atmosphere, after standing to room temperature, after grinding, the particle size is about 5 μm (LAPRCABASR) 0.2(CoCrfemnni) 0.2 O 3-δ Pre-generic powder.

[0047] The powder was pressed into a membrane green body under 18 MPa pressure by a stainless steel mold having an inner diameter of 14 mm, and the heating rate was controlled to 4 ° C / min, and the film green body was sintered at 1200 ° C for 12 h, and the rate of 2 ° C / min was lowered to room temperature, That is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com