Garbage incinerator boiler tube applied to working condition with temperature lower than 400 DEG C and production method thereof

A technology of waste incinerator and production method, which is applied in the direction of combustion method, incinerator, process efficiency improvement, etc., to achieve the effects of prolonging service life, excellent corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

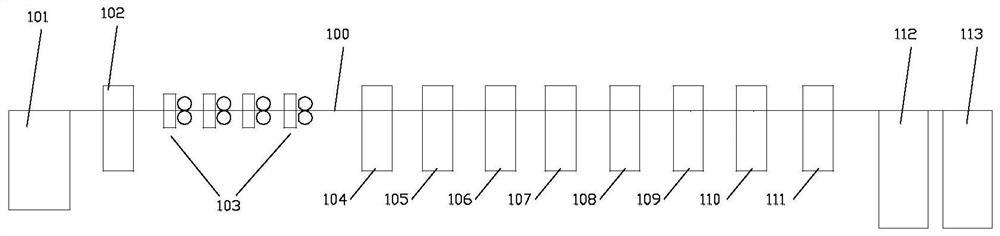

[0057] Embodiment 1: a production method of a waste incinerator boiler tube applied to a temperature condition lower than 400 ° C, comprising the following steps:

[0058] Step S1, converter smelting to obtain rough molten steel:

[0059] The weight percent content of the first component by the converter is: the components and weight percent content of the first component are: carbon: 0.12%, silicon: 0.46%, manganese: 0.35%, phosphorus: 0.014%, sulfur: 0.010% , nickel: 32%, chromium: 22%, molybdenum: 3%, copper: 0.4%, tungsten 0.6%, aluminum: 0.3%, titanium: 0.24%, the rest is Fe and inevitable impurities, refining, to obtain crude molten steel;

[0060] Step S2, refining to obtain refined molten steel:

[0061] The crude molten steel smelted in step S1 is passed through a refining furnace to reduce the inclusion content in the steel as much as possible, so as to ensure stable performance and good surface quality of the product, and obtain refined molten steel.

[0062] In ...

Embodiment 2

[0085] Embodiment 2: the preparation method of the anti-corrosion layer 12 of the waste incinerator boiler tube 1 further comprising the waste incinerator boiler tube 1, comprising the following steps:

[0086] Step S10: Smelting the raw materials of the second component to obtain a bar:

[0087] The components and weight percentages of the second component are: chromium: 22%, aluminum: 6%, carbon: 0.08%, boron 3%, silicon 2%, and the balance is nickel and inevitable impurities. Electric smelting and casting into bars, wherein the smelting temperature is 1050±30℃;

[0088] Step S11: Use a wire drawing machine to draw the bar to obtain a special wire for the anti-corrosion layer 12 of the boiler tube of the waste incinerator:

[0089] Put the bar into the electric furnace at 800-900℃ for heat treatment for 9-12 hours, anneal it in the vacuum annealing furnace at 150-250℃ for 1-3 hours, and use the wire drawing machine to reduce the diameter and draw for 8-10 times. Special wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com