Preparation method of coating for difunctional catalyst applied to electrolysis of water

A catalyst and water electrolysis technology, applied in the field of water electrolysis, can solve the problem of high preparation cost, and achieve the effects of simple preparation process, excellent hydrogen evolution and oxygen evolution catalytic performance, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a bifunctional electrolytic water catalyst coating, the method comprising the following steps:

[0027] (1) Base material selection and pretreatment

[0028] The polycrystalline graphite rod is selected as the base electrode material, and its circular cross-section is used as the electrode surface, with an area of 0.0707cm 2 ; The side is insulated and sealed, and the surface of the electrode is smoothed on 800-grit sandpaper.

[0029] The base electrode was ultrasonically cleaned in 3.0mol / L HCl for 10 minutes, then ultrasonically cleaned in water and absolute ethanol for 2 minutes each, rinsed with running water, dried, and set aside.

[0030] (2) The first step of plating

[0031] Prepare 40ml of electroplating solution, which contains 0.3mol / L nickel nitrate, 0.1mol / L phosphomolybdic acid, 0.3mol / L, sodium citrate, and 0.1mol / L boric acid.

[0032] At room temperature of 25°C, using constant current method, with the substrate electrode as...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the base electrode material is different. In this embodiment, a nickel mesh with a thickness of 1.0mm is selected as the base electrode material, and a thickness of 5.0×5.0cm is selected. 2 The surface of the material is the electrode surface, and the surface of the material is free of grinding. The cleaning of the nickel mesh base electrode, the electroplating solution and the plating conditions of the first step and the second step of plating are all the same as in Example 1.

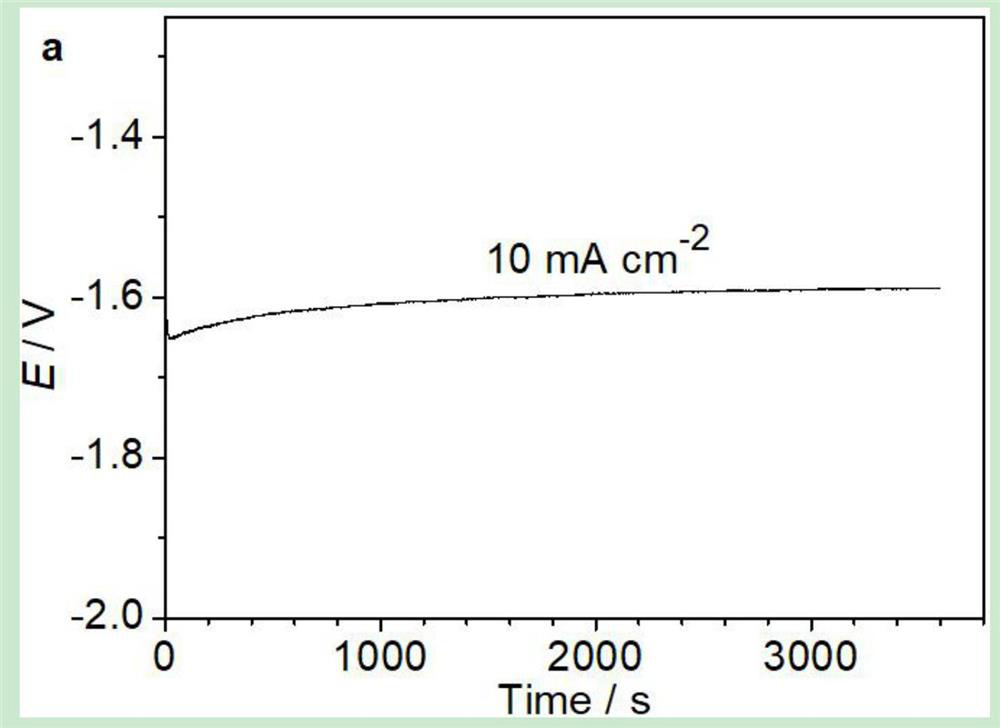

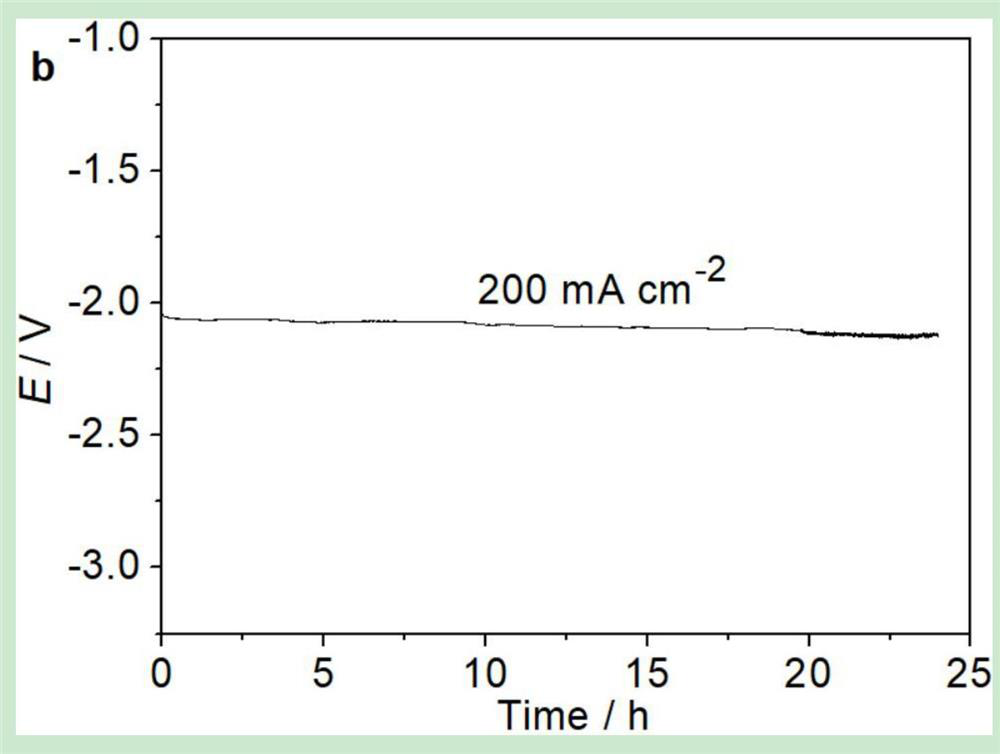

[0040] The electrochemical test is the same as in Example 1. The voltage-time curve of the two electrodes for total water splitting is shown in Figure 4 and Figure 5 . From Figure 4 and Figure 5 It can be concluded that in 1.0mol / L KOH, when the catalytic electrode is based on nickel mesh, the total water splitting current density is 10mA / cm 2 with 300mA / cm 2 , the required voltages are about -1.61V and -2.37V respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com