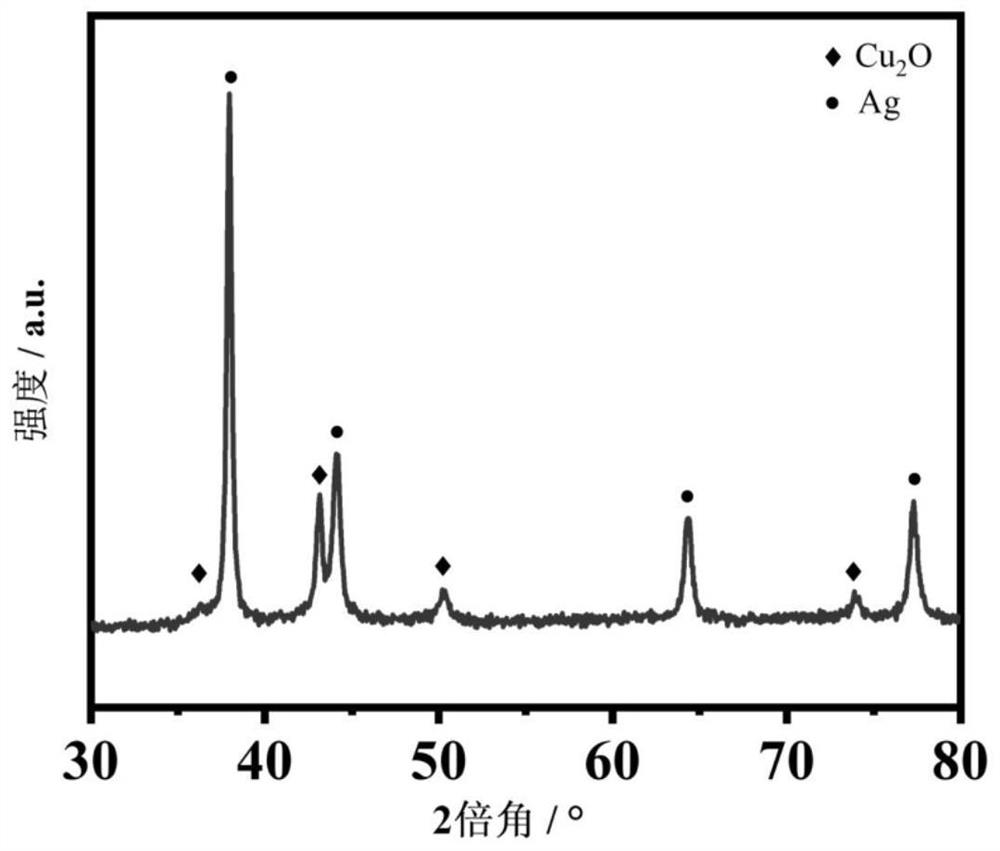

Ag@Cu2O core-shell structure nanosphere catalyst as well as preparation method and application thereof

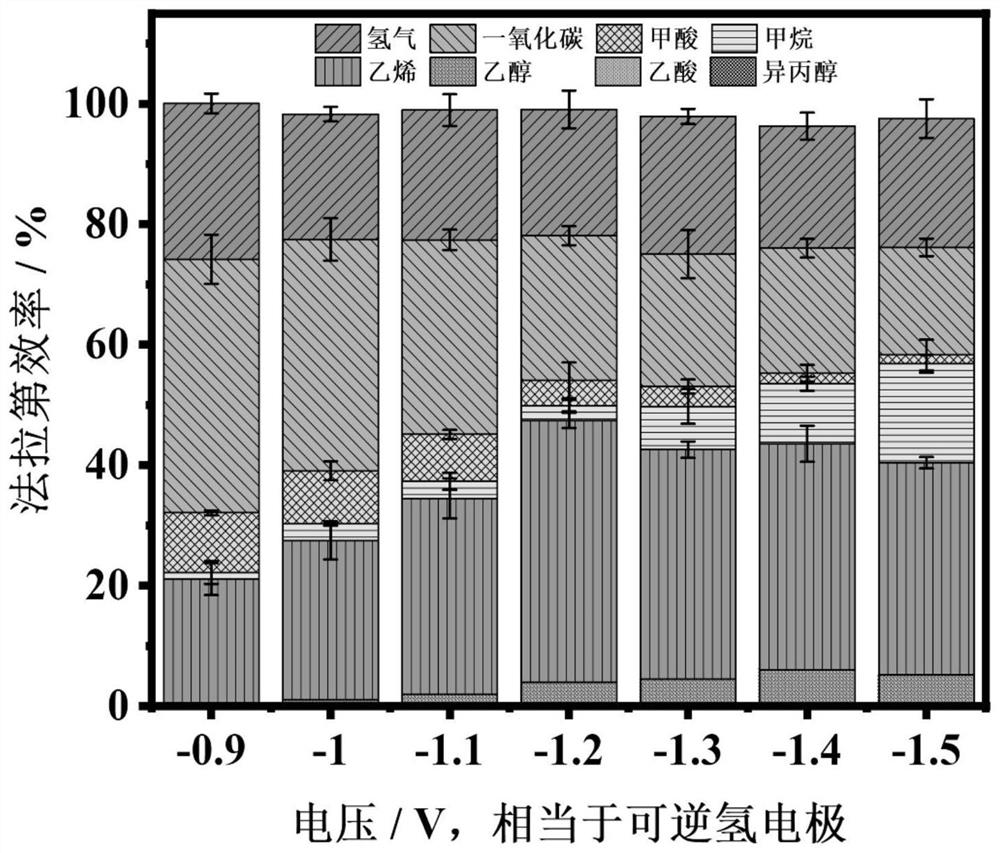

A core-shell structure and nanosphere technology, applied in the field of electrocatalysis, can solve the problems of limited practical application and commercialization, slow electron transfer kinetics, low product selectivity, etc., achieve excellent C2+ selectivity, easy to control the preparation process, The effect of enhancing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Provides an Ag@Cu 2 The preparation method of O core-shell structure nanosphere catalyst specifically comprises the following steps:

[0034] 1) Preparation of silver nanosphere inner core

[0035] Weigh 0.5g of PVA and dissolve it in 50ml of deionized water to obtain a 1% PVA aqueous solution, add 16.987mg of AgNO to the 1% PVA aqueous solution 3 And fully stirred at room temperature for 2 hours to ensure that the silver salt and the PVA aqueous solution are fully mixed, and 2ml 30% hydrazine hydrate is added to the above mixed solution to obtain a silver nanosphere dispersion;

[0036] 2) Preparation of Ag@Cu 2 O core-shell nanospheres

[0037] With the silver nanosphere dispersion that step 1) obtains, add 24.16mg Cu (NO 3 ) 2 ·3H 2 O and fully stirred at room temperature for 2 hours to ensure that the copper salt and the silver nanosphere dispersion were fully mixed, and 4ml of 30% hydrazine hydrate reducing agent was added to the above mixture, centrifuged, w...

Embodiment 2

[0044] (Compared with Example 1, we have changed the amount of copper salt added to preparation step 1) PVA aqueous solution concentration, preparation step 2)

[0045] Provides an Ag@Cu 2 The preparation method of O core-shell structure nanosphere catalyst specifically comprises the following steps:

[0046] 1) Preparation of silver nanosphere inner core

[0047] Weigh 1g of PVA and dissolve it in 50ml of deionized water to obtain a 2% PVA aqueous solution, add 16.987mg of AgNO to the 2% PVA aqueous solution 3 And fully stirred at room temperature for 2 hours to ensure that the silver salt and the PVA aqueous solution are fully mixed, and 2ml 30% hydrazine hydrate is added to the above mixed solution to obtain a silver nanosphere dispersion;

[0048] 2) Preparation of Ag@Cu 2 O core-shell nanospheres

[0049] With the silver nanosphere dispersion that step 1) obtains, add 48.32mg Cu (NO 3 ) 2 ·3H 2 O and fully stirred at room temperature for 2 hours to ensure that the ...

Embodiment 3

[0054] (Compared with Example 2, we have changed the amount of copper salt added in preparation step 2))

[0055] Provides an Ag@Cu 2 The preparation method of O core-shell structure nanosphere catalyst specifically comprises the following steps:

[0056] 1) Preparation of silver nanosphere inner core

[0057] With embodiment 2 preparation step 2);

[0058] 2) Preparation of Ag@Cu 2 O core-shell nanospheres

[0059] With the silver nanosphere dispersion that step 1) obtains, add 72.48mg Cu (NO 3 ) 2 ·3H 2 O and fully stirred at room temperature for 2 hours to ensure that the copper salt and the silver nanosphere dispersion were fully mixed, and 4ml of 30% hydrazine hydrate reducing agent was added to the above mixture, centrifuged, washed, and dried to obtain Ag@Cu 2 O core-shell structured nanosphere electrocatalysts.

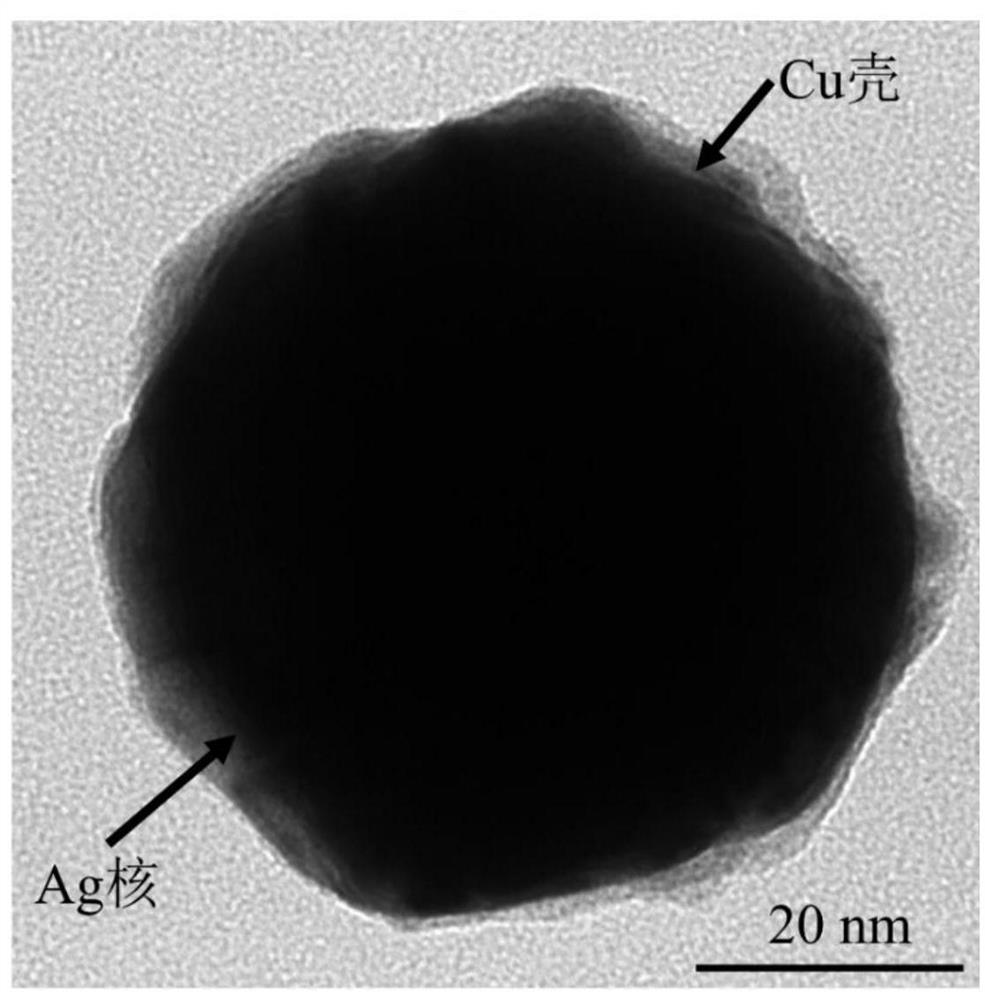

[0060] Figure 6 Ag@Cu prepared for Example 3 2 The transmission diagram of O core-shell structure nanospheres, it can be seen from the figure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com