Method for measuring trace hydroxyl value of modified polyphenyl ether

A determination method and polyphenylene ether technology, applied in the field of detection, can solve the problems of titration hydroxyl value, no detection process, quantitative analysis of difficult phenolic hydroxyl groups, etc., and achieve short detection time, broad prospects and practical value, and high detection precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

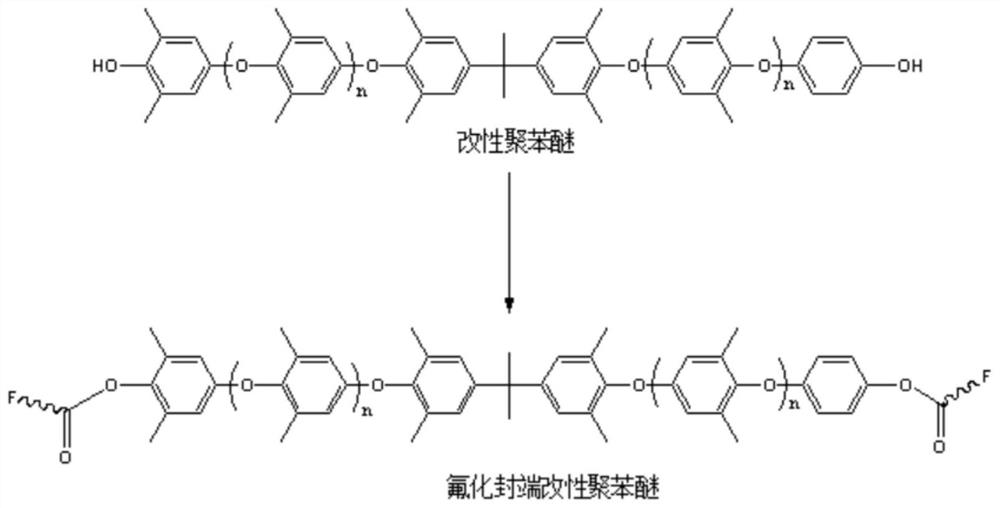

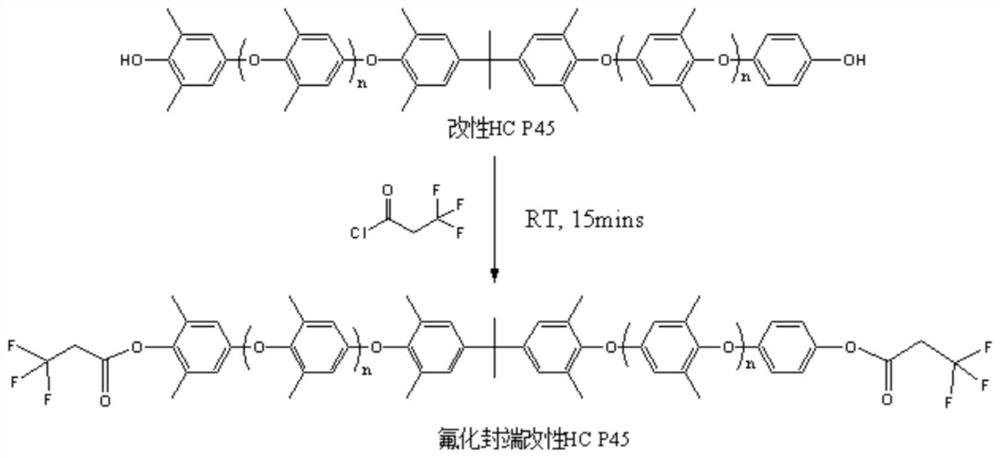

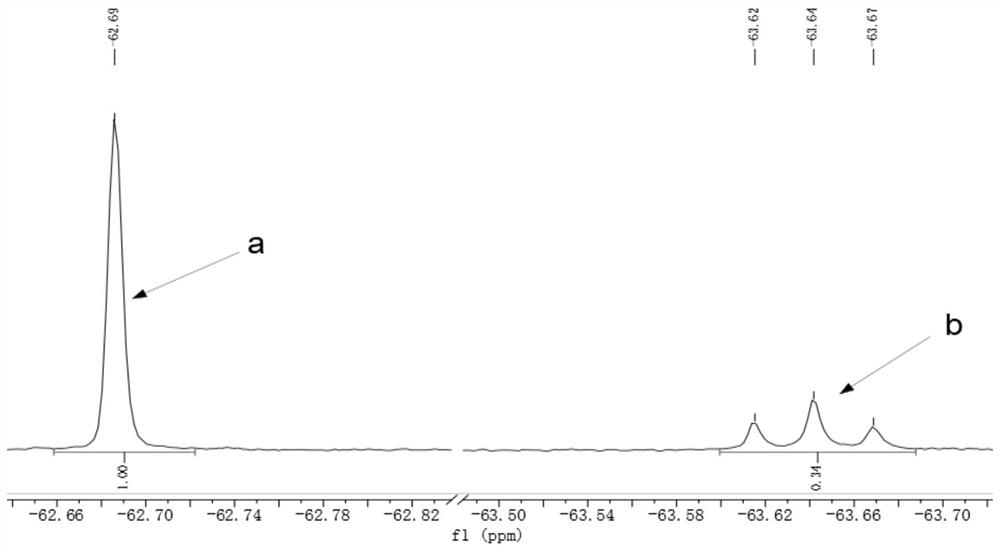

[0038] (1) Modified polyphenylene ether fluorination

[0039] Add 0.5 g of dried modified polyphenylene ether HC P45 sample (Zhuhai Hongchang Electronic Materials Co., Ltd., Zhuhai, China) into a 10 ml injection bottle, add 5 mg of potassium carbonate powder and 3 ml of anhydrous chloroform, and stir to dissolve. Inject about 6.46mg of 3,3,3-trifluoropropionyl chloride (CAS No.41463-83-6) with a needle, the molar ratio of modified polyphenylene ether HC P45 to trifluoropropionyl chloride is about 1:5, and stir magnetically at room temperature Response 15mins. After the reaction is complete, add 20ml of methanol solution, wait for solids to precipitate, remove the solvent by suction filtration, and repeat washing three times to obtain fluorinated modified polyphenylene ether powder, which can be dried in a vacuum oven at 40°C overnight to obtain fluorinated modified polyphenylene ether . The fluorination reaction formula is as figure 2 .

[0040] (2) NMR sample preparation...

Embodiment 2

[0047] (1) Modified polyphenylene ether fluorination

[0048] Add 0.5 g of dried modified polyphenylene ether HC P45 sample (Zhuhai Hongchang Electronic Materials Co., Ltd., Zhuhai, China) into a 10 ml injection bottle, add 5 mg of potassium carbonate powder and 3 ml of anhydrous chloroform, and stir to dissolve. Inject about 6.46mg of 3,3,3-trifluoropropionyl chloride with a needle, the molar ratio of modified polyphenylene ether HC P45 to trifluoropropionyl chloride is about 1:5, and react with magnetic stirring at room temperature for 30mins. After the reaction is complete, add 20ml of methanol solution, wait for solids to precipitate, remove the solvent by suction filtration, and repeat washing three times to obtain fluorinated modified polyphenylene ether powder, which can be dried in a vacuum oven at 40°C overnight to obtain fluorinated modified polyphenylene ether .

[0049] (2) NMR sample preparation and detection

[0050] Weigh 44.09 mg (accurate to 0.01 mg) of the ...

Embodiment 3

[0056] (1) Modified polyphenylene ether fluorination

[0057] Add 0.5 g of dried modified polyphenylene ether Sabic SA 9000 sample (SABIC, Saudi Arabia) into a 10 ml injection bottle, add 5 mg of potassium carbonate powder and 3 ml of anhydrous chloroform, and stir to dissolve. Inject about 8.58mg of 2,4,5-trifluorobenzoyl chloride (CAS No.88419-56-1) with a needle, and the molar ratio of modified polyphenylene ether Sabic SA9000 to 2,4,5-trifluorobenzoyl chloride is about 1 : 5, magnetic stirring reaction at room temperature for 15mins. After the reaction is complete, add 20ml of methanol solution, wait for solids to precipitate, remove the solvent by suction filtration, and repeat washing three times to obtain fluorinated modified polyphenylene ether powder, which can be dried in a vacuum oven at 40°C overnight to obtain fluorinated modified polyphenylene ether .

[0058] (2) NMR sample preparation and detection

[0059] Weigh 52.42 mg of fluorinated modified polyphenylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com