MEMS structure

A backplane, piezoelectric composite technology, applied in the field of MEMS structure, can solve the problems of restricting development, no considerable improvement, low sensitivity of piezoelectric MEMS microphone, etc., to achieve high sensitivity and improve the effect of output electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

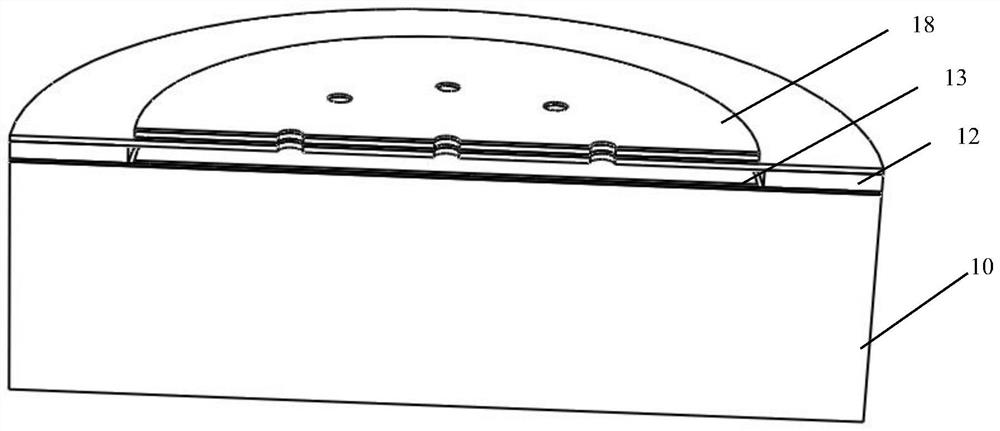

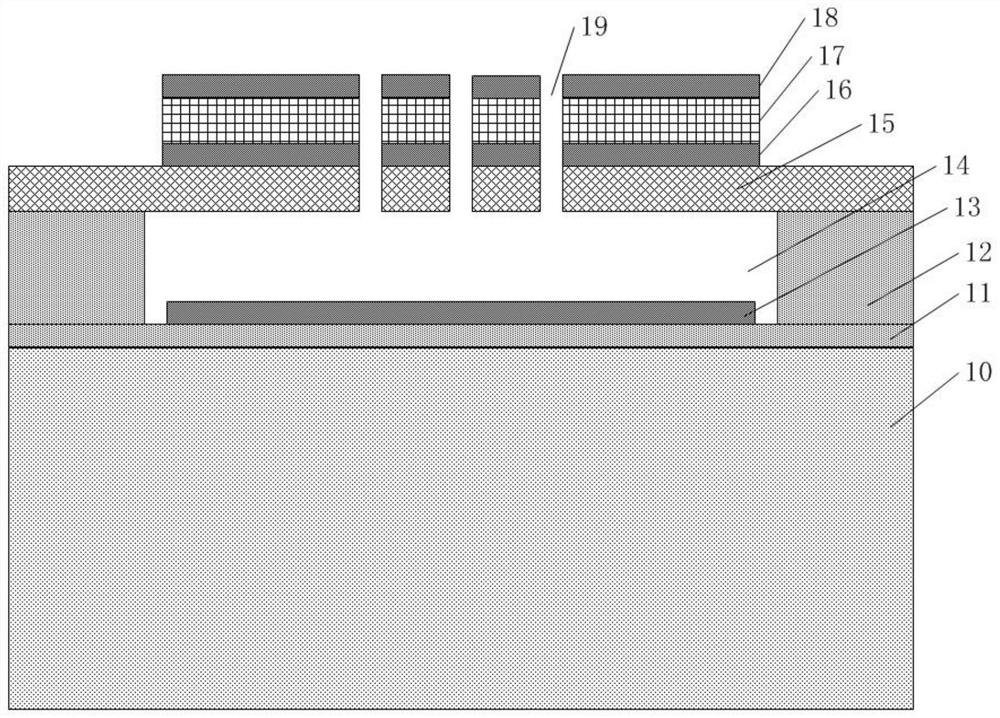

[0028] Substrate 10 comprises silicon or any suitable silicon-based compound or derivative (e.g. silicon wafer, SOI, SiO 2 / polysilicon on Si). A passivation layer 11 is formed on the substrate 10, and the material of the passivation layer 11 includes silicon dioxide and silicon nitride. A backplane 13 is formed over the passivation layer 11 . The first spacer layer 12 is formed on the passivation layer 11 and separated from the backplane 13 , and the material of the first spacer layer 12 includes silicon dioxide or PSG (phospho-silicate Glass, ie phospho-silicate glass).

[0029] The vibration support layer 15 is formed above the first spacer layer 12 and is suspended above the cavity 14 . The material of vibration supporting layer 15 comprises silicon nitride (Si 3 N 4 ), silicon oxide, single crystal silicon, polycrystalline silicon single-layer or multi-layer composite film structure or other suitable supporting materials. The first electrode layer 16 is formed over t...

Embodiment 2

[0034] It is worth noting that the same components use the same symbols in Embodiment 2 and Embodiment 1, and the materials used are also basically the same, which will not be repeated here.

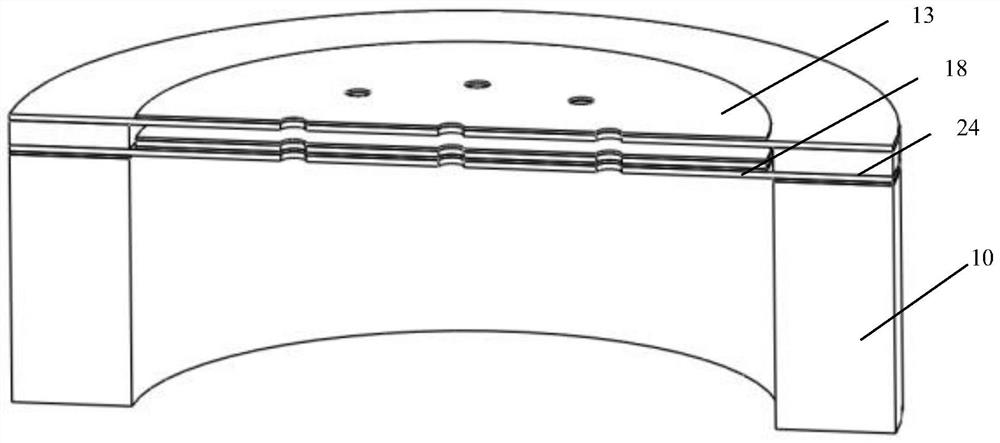

[0035] see image 3 and Figure 4 , the MEMS structure includes a barrier layer 21 formed over the substrate 10 . The material of the barrier layer 21 includes thermally oxidized silicon dioxide.

[0036] The MEMS structure also includes a vibration support layer 15 , a first electrode layer 16 , a piezoelectric layer 17 and a second electrode layer 18 sequentially formed over the barrier layer 21 .

[0037] The second spacer layer 24 is formed over the barrier layer 21 and spaced apart from the first electrode layer 16 . The material of the second spacer layer 24 may be the same as that of the first spacer layer 12 . The back plate 13 is formed over the second spacer layer 24 .

[0038] It can be known from the above description that the piezoelectric composite vibration layer is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com