Preparation method of high-purity nitric oxide and application of high-purity nitric oxide in semiconductor manufacturing process

A nitric oxide and semiconductor technology, applied in the field of high-purity nitric oxide preparation, can solve the problems of being susceptible to shock or explosion, and adversely affected by the purity of nitric oxide, and achieve the effects of reducing disproportionation, prolonging residence time, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

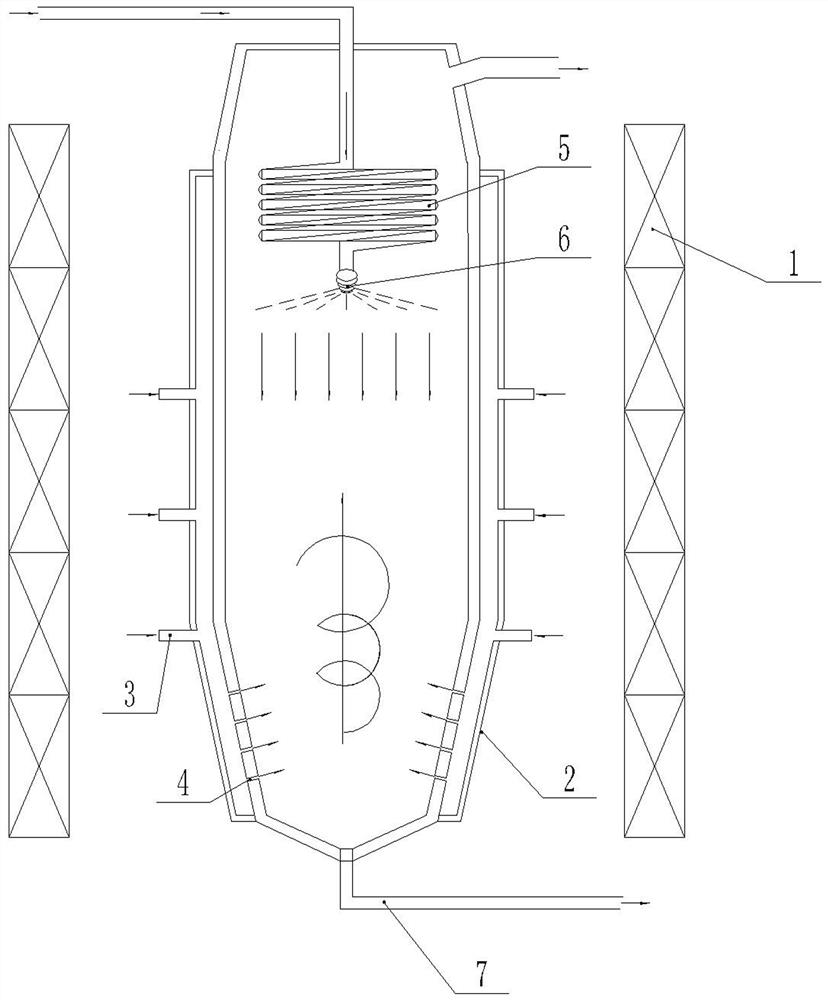

[0041] A preparation method of high-purity nitric oxide, comprising the following steps:

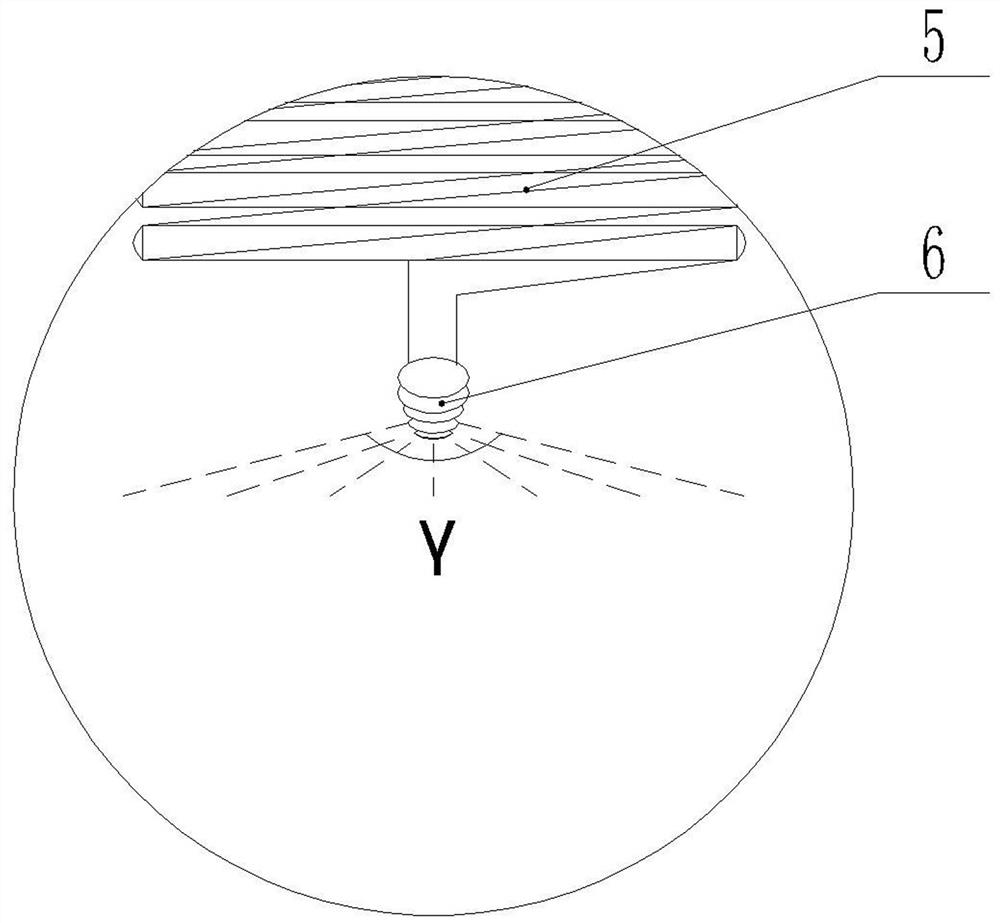

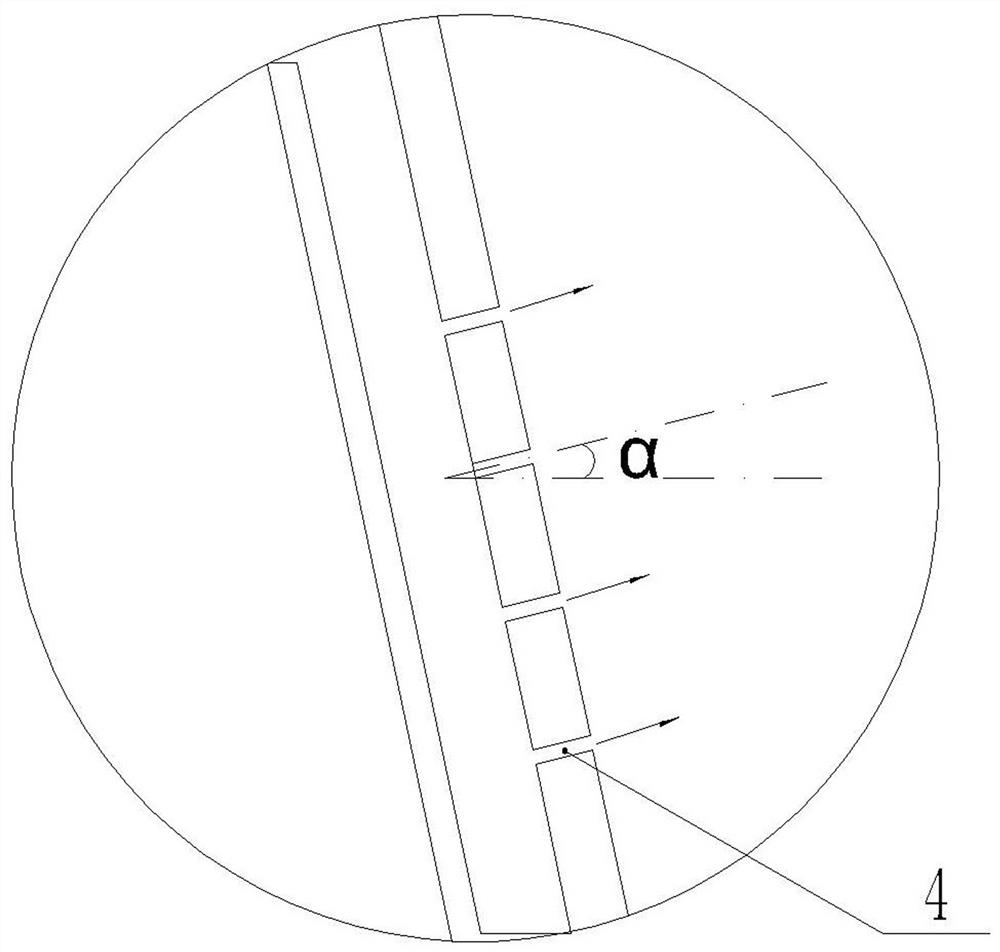

[0042] (1) Feed nitrogen monoxide feed gas from FeSO at a flow rate of 0.5~5kg / h 4 The lower part of the adsorption tower is attached to FeSO 4 The inner wall of the adsorption tower is obliquely upward into FeSO 4 In the adsorption tower, in FeSO 4 An upward vortex is formed in the adsorption tower; the FeSO 4 The solution passes through the FeSO 4 The spiral spray pipe in the upper part of the adsorption tower is sprayed into FeSO from one or more spiral nozzles 4 In the adsorption tower; the FeSO 4 The adsorption tower is equipped with a gradient magnetic field whose magnetic field strength increases from top to bottom and the direction of the magnetic field is downward. FeSO 4 When the solution flows along the spiral spray pipe and after being sprayed out by the spiral nozzle, the magnetic induction line is cut; the control of FeSO 4 The pressure in the adsorption tower is con...

Embodiment 1

[0046] A preparation method of high-purity nitric oxide, comprising the following steps:

[0047] (1) Feed the nitrogen monoxide feed gas into the feed gas inlet pipe at a flow rate of 1.4±0.2kg / h, and feed FeSO with a concentration of 3mol / L 4 The solution is passed into FeSO from the spiral spray pipe 4 In the adsorption tower, control FeSO 4 The temperature in the adsorption tower is 20±2°C and the pressure is 19±1psi, so that the nitric oxide feed gas and FeSO 4 solution in FeSO 4 The adsorption tower contacts with each other and a complexation reaction occurs, and the obtained adsorption liquid is discharged from the bottom of the tower without being absorbed by FeSO 4 The gas absorbed by the solution is discharged from the top of the tower;

[0048] (2) Pass the adsorption liquid into the heat exchanger, raise the temperature to 90±2°C, pass it into the NO desorption tower for desorption, and pass the desorbed gas into the cryogenic condenser from the top of the NO d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com