Plate-shaped crystal tungsten carbide powder, preparation method thereof and hard alloy

A technology of tungsten carbide powder and cemented carbide, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problem that the number and size of plate-shaped WC grains are difficult to control, the proportion of plate-shaped grains is small, and the hardness of cemented carbide is , toughness and other comprehensive properties cannot be effectively improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

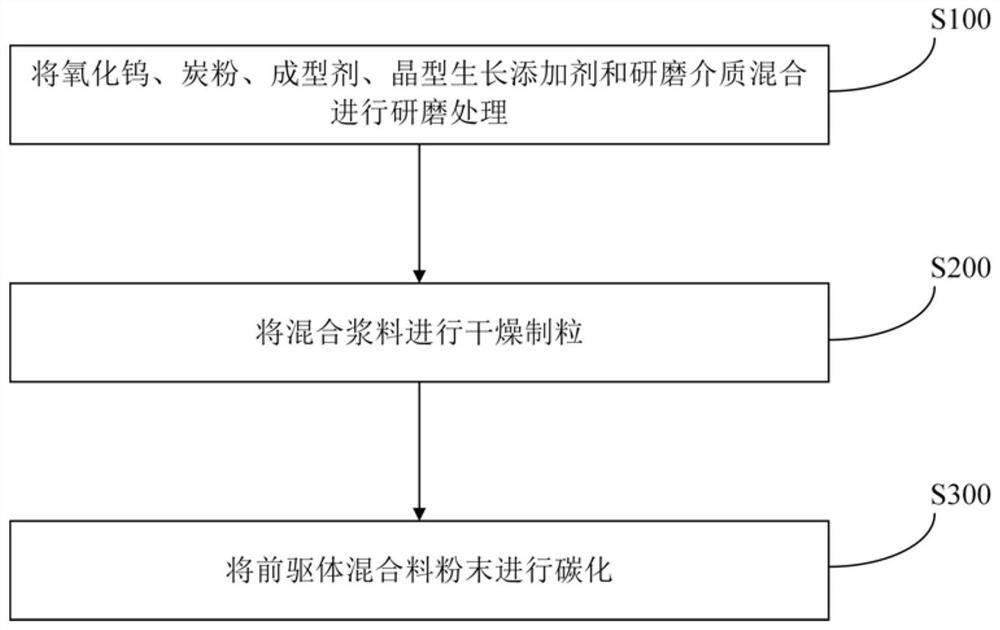

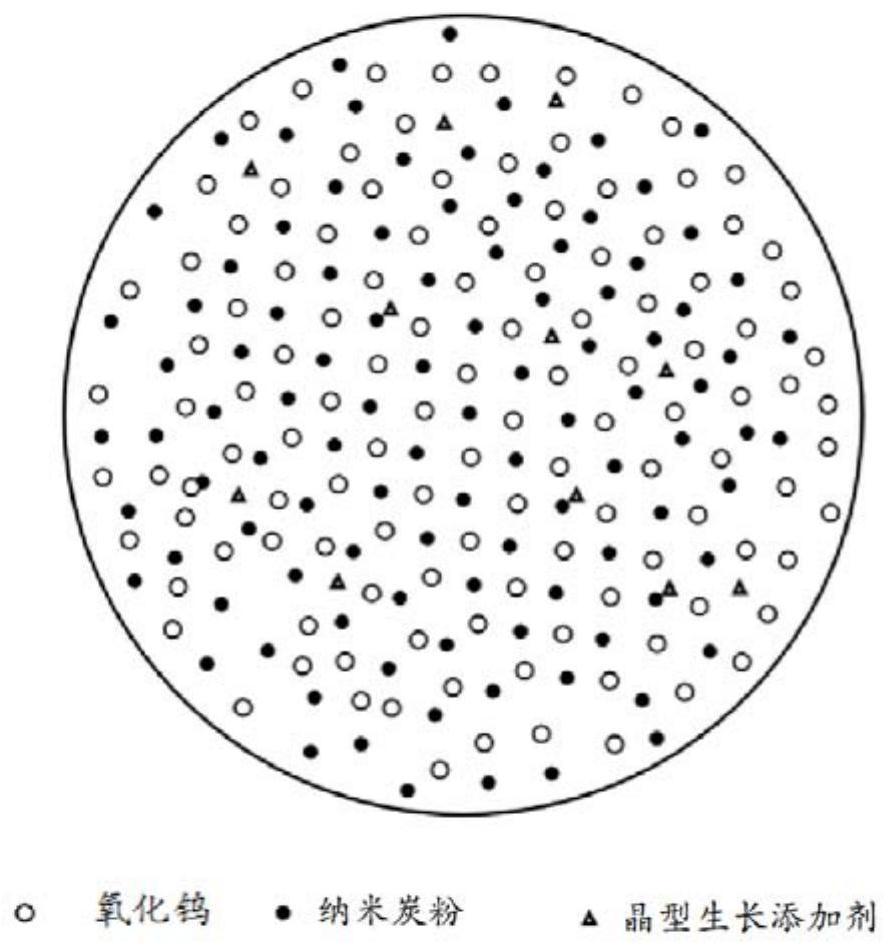

[0055] Step 1: Ingredients WO 3 165.4kg, 27.8kg of natural gas carbon black (particle size is 100-400nm), chromium carbide 1.766kg (1.2% batching mass ratio) of Fibonacci particle size is 0.8 μm, grinds 600kg of alloy balls, and the ball-to-material ratio is 3:1, and then Add 100 liters of grinding medium pure water and 5.0 kg (2.5% batching mass ratio) of forming agent PVA (polyvinyl alcohol) into the wet mill, and grind the alloy balls under cooling water conditions for grinding. The grinding time is as shown in Table 1 , wet mill parameters 300L, speed 37 rpm, after grinding WO 3 The average particle size of carbon black is not greater than 0.2 μm, and the average particle size of carbon black after grinding is not greater than 0.3 μm;

[0056] Step 2: Transfer the homogeneously mixed slurry obtained in step 1 into a stirring container, and dry and granulate in a spray drying tower under hot air. The grain size requires 500-mesh sieving to remove fine powder below 10 μm an...

Embodiment 2

[0063] Step 1: Ingredients WO 3 165.4kg, 27.8kg of natural gas carbon black (particle size is 100-400nm), chromium carbide 1.766kg (1.2% batching mass ratio) of Fibonacci particle size is 0.8 μm, grinds 600kg of alloy balls, and the ball-to-material ratio is 3:1, and then 100 liters of grinding medium pure water and 5.0 kg (2.5% batching mass ratio) of forming agent PVA (polyvinyl alcohol) are added to the wet mill, and the grinding alloy balls are ground under cooling water conditions for 10 hours. Mill parameter 300L, speed 37 rpm, WO after grinding 3 The average particle size of carbon black is not greater than 0.2 μm, and the average particle size of carbon black after grinding is not greater than 0.3 μm;

[0064] Step 2: Transfer the homogeneously mixed slurry obtained in step 1 into a stirring container, and dry and granulate in a spray drying tower under hot air. The grain size requires 500-mesh sieving to remove fine powder below 10 μm and prepare for sintering;

...

Embodiment 3

[0071] Step 1: Ingredients WO 3 : 165.4kg, 27.8kg of natural gas carbon black (particle size 100-400nm), 4.498kg of chromium carbide with a Fischer particle size of 0.8μm (3.0% batching mass ratio), 600kg of grinding alloy balls, the ball-to-material ratio is 3:1, Add 100 liters of grinding medium pure water and 5.0 kg (2.5% batching mass ratio) of forming agent PVA (polyvinyl alcohol) into the wet mill, and grind the alloy balls under cooling water conditions to carry out the grinding process. The grinding time is 10 hours. The parameters of the wet mill are 300L, the speed is 37 rpm, and the WO after grinding 3 The average particle size of carbon black is not greater than 0.2 μm, and the average particle size of carbon black after grinding is not greater than 0.3 μm;

[0072] Step 2: Transfer the homogeneously mixed slurry obtained in step 1 into a stirring container, and dry and granulate in a spray drying tower under hot air. The grain size requires sieving to 625 mesh t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com