Method for prolonging continuous operation cycle of sludge wet oxidation

A technology of wet oxidation and operation cycle, which is applied in the direction of oxidation treatment of sludge, etc., can solve the problems of oil resources not being recycled, incineration method consumes a lot of energy, and will produce secondary pollution, etc., so as to prolong the continuous operation cycle, control safety, Avoid overheating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

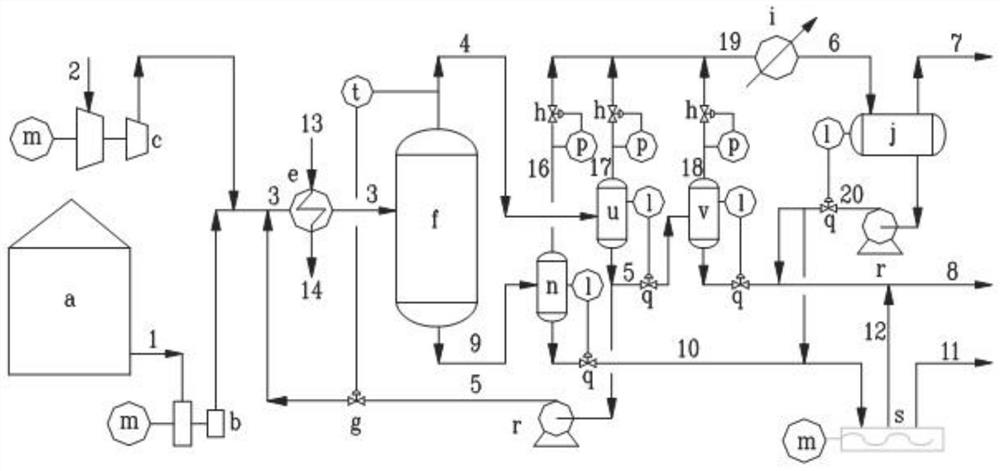

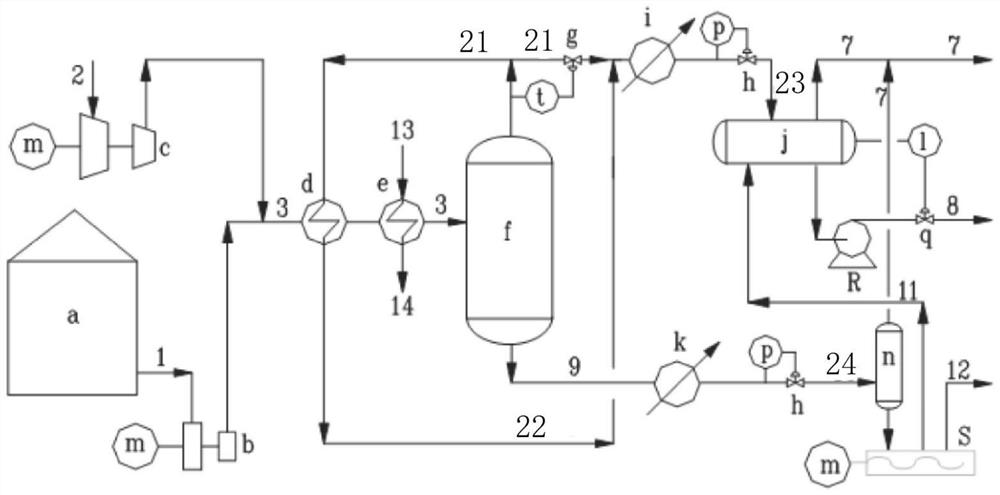

[0022] Such as figure 1 As shown, the present invention provides a technical solution: a method for prolonging the continuous operation period of sludge wet oxidation, characterized in that: comprising the following steps:

[0023] S1. The high-temperature oxidation sludge effluent from the top of the sludge wet oxidation reactor is subjected to high-pressure flash degassing, and the degassed high-temperature oxidation sludge stream is partially circulated back to the reactor inlet pipe and mixed with raw materials to heat the raw materials. Through flexible Control the flow rate of circulating oxidized sludge to adjust the reaction temperature in the reactor;

[0024] S2. Another part of the oxidized sludge after degassing is subjected to low-pressure flash evaporation to reduce the temperature of the oxidized sludge, and the high-temperature sandy sludge at the bottom of the reactor is subjected to low-pressure flash evaporation to reduce the temperature of the sandy sludge;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com