Hydrophobic decorative base paper and preparation method thereof

A decorative base paper and hydrophobic technology, which is applied in the field of decorative paper, can solve the problems of decorative base paper being prone to moisture and mildew, difficulties in the treatment of papermaking white water, and reduced paper absorption capacity, so as to improve dry and wet tensile strength, antibacterial and mildew resistance, and water solubility. sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

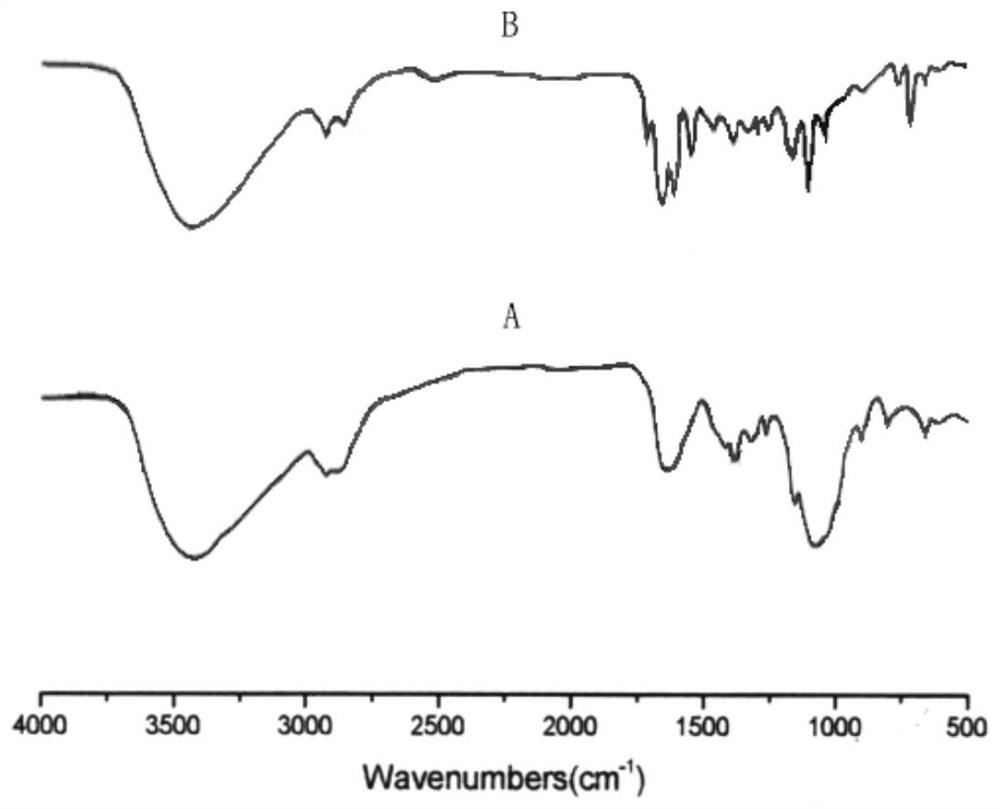

[0055] The preparation method of described chitosan derivative comprises:

[0056] 1) Add 1 part by weight of chitosan (the degree of deacetylation is 60-80%, and the molecular weight is 100,000-300,000) into the hydrochloric acid / oxalic acid mixed solution, stirring and dissolving, and the mass fraction of hydrochloric acid in the mixed solution is 2-5%, The mass fraction of oxalic acid is 1 to 3%, add 3.5 to 5 parts by weight of 4-methacryloxyethyl trimellitic anhydride, stir and react at 50 to 60°C for 2 to 8 hours, cool to room temperature, soak the product in ethanol for dehydration, and precipitate , filter, wash with ethanol, acetone, deionized water successively, dry to obtain 4-methacryloyloxyethyl trimellitic anhydride modified chitosan;

[0057] 2) Add 4-methacryloyloxyethyl trimellitic anhydride modified chitosan into the sodium hydroxide solution, then add 2 to 3 parts by weight of benzyl glycidyl ether, stir and react at 45 to 60°C for 2 to 6 hours, Cool to room...

Embodiment 1

[0073] The present embodiment provides a chitosan derivative, which is prepared by the following method:

[0074] 1) 1 weight part of chitosan (deacetylation degree 72%, molecular weight is 200,000) is added to the hydrochloric acid / oxalic acid mixed solution of 49 weight parts (the massfraction of hydrochloric acid in the mixed solution is 3%, the massfraction of oxalic acid is 2 %), stir to dissolve, add 4.5 parts by weight of 4-methacryloyloxyethyl trimellitic anhydride, stir and react at 55°C for 6h, cool to room temperature, soak the product in ethanol for dehydration, precipitate, filter, and use ethanol, acetone, Washing with deionized water, drying at 50°C to obtain 4-methacryloyloxyethyl trimellitic anhydride modified chitosan;

[0075] 2) Add 4-methacryloyloxyethyl trimellitic anhydride modified chitosan to 50 parts by weight, 2wt% sodium hydroxide solution, add 3 parts by weight benzyl glycidyl ether, and stir for 4 hours at 50°C , cooled to room temperature, adjus...

Embodiment 2

[0077] This embodiment provides another chitosan derivative, which is prepared by the following method:

[0078] 1 weight part chitosan (deacetylation degree 72%, molecular weight is 200,000) is added to the hydrochloric acid / oxalic acid mixed solution of 49 weight parts (the massfraction of hydrochloric acid is 3%, the massfraction of oxalic acid is 2% in the mixed solution) , stir to dissolve, add 0.5 parts by weight of 4-methacryloyloxyethyl trimellitic anhydride, stir and react at 55°C for 6h, cool to room temperature, soak the product in ethanol for dehydration, precipitate, filter, and use ethanol, acetone, deionized Washing with water and drying at 50° C. to obtain 4-methacryloyloxyethyl trimellitic anhydride modified chitosan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com