Crude tea extract/chitosan oligosaccharide nanoparticle effervescent cream material, preparation method and application

A nanoparticle and extract technology, applied in applications, pharmaceutical formulations, food science, etc., can solve the problems of fast effervescent reaction rate, inability to maintain a mixed state, difficult to form a uniform dispersed self-assembly to create an environment, etc., to reduce Energy consumption, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

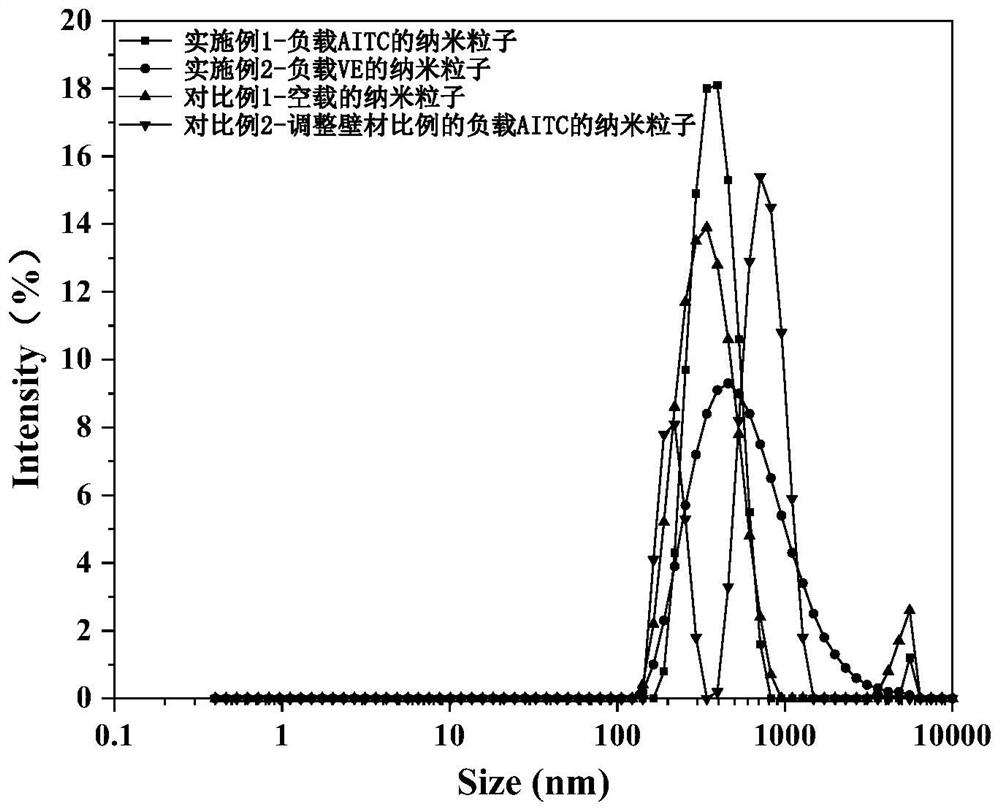

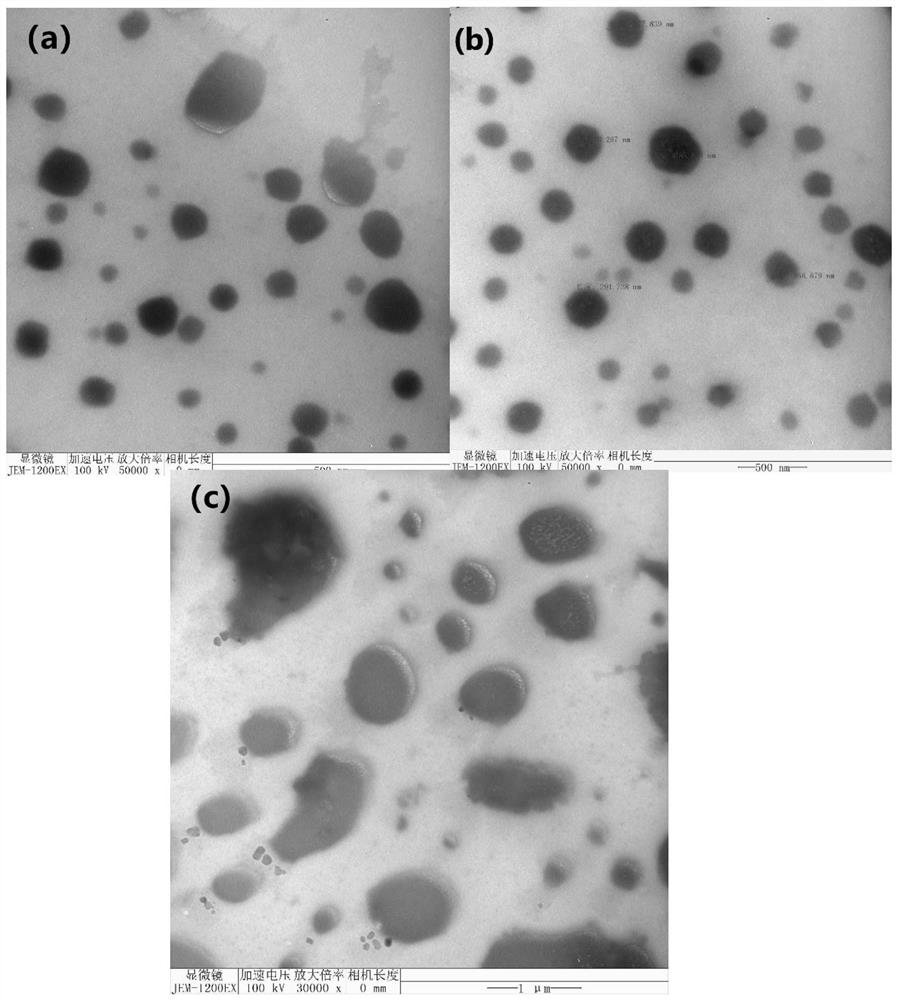

Embodiment 1

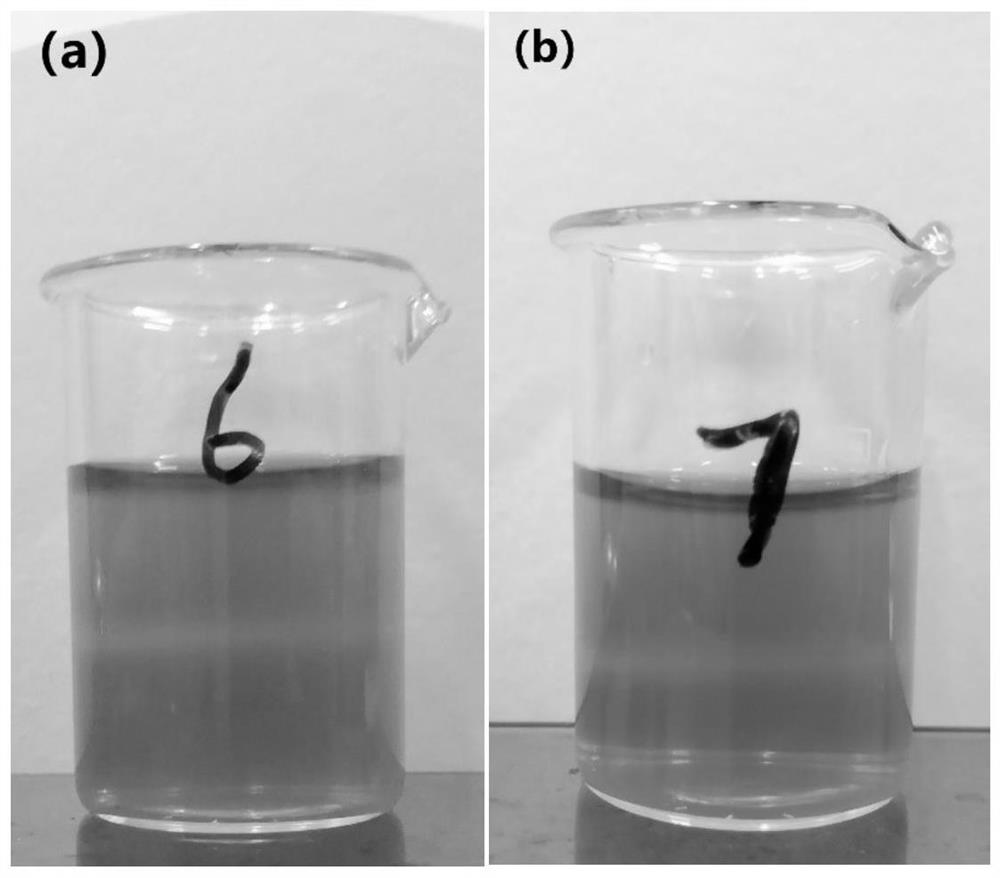

[0051] A kind of preparation of the crude tea extract / chitooligosaccharide nanoparticle effervescent paste of allyl isothiocyanate (AITC), adopts the following steps:

[0052] S1: Take respectively 70 parts of crude tea extract rich in tea polysaccharide as wall material, 30 parts of chitosan oligosaccharide, 180 parts of citric acid and 280 parts of sodium bicarbonate solid as the acid and alkali in the effervescent agent and grind and grind to After there are no obvious large particles, sieve, the mesh should be ≥ 40 mesh, dry and store for later use;

[0053] S2: Put the crude tea extract, chitosan oligosaccharide, citric acid and sodium bicarbonate in the used S1 into the freeze dryer for 24 hours to dry. In order to ensure the stability of the paste during storage, the samples used should be as dry as possible;

[0054] S3: Mix PEG-600, which is liquid at normal temperature, and PEG-800, which is waxy solid at normal temperature, to adjust the appropriate carrier viscosit...

Embodiment 2

[0062] The preparation of a crude tea extract / chitooligosaccharide nanoparticle effervescent cream loaded with vitamin E (Vitamin, VE) adopts the following steps:

[0063] S1: Take respectively 80 parts of crude tea extract rich in tea polysaccharide as wall material, 20 parts of chitosan oligosaccharide, 180 parts of citric acid and 280 parts of sodium bicarbonate solid as acid and alkali in the effervescent agent and grind to After there are no obvious large particles, sieve, the mesh should be ≥ 40 mesh, dry and store for later use;

[0064] S2: Put the crude tea extract, chitosan oligosaccharide, citric acid and sodium bicarbonate in S1 into the freeze dryer for 48 hours to dry. In order to ensure the stability of the paste during storage, the samples used should be as dry as possible;

[0065] S3: Mix PEG-600, which is liquid at normal temperature, and PEG-800, which is waxy solid at normal temperature, to adjust the appropriate carrier viscosity and the amount of co-emul...

Embodiment 3

[0069] A kind of preparation of the crude tea extract / chitooligosaccharide nanoparticle effervescent paste of allyl isothiocyanate (AITC), adopts the following steps:

[0070] S1: Take 50 parts of crude tea extract rich in tea polysaccharide as wall material, 10 parts of chitosan oligosaccharide, 150 parts of tartaric acid as acid and alkali in effervescent agent, and 160 parts of sodium carbonate solid, and grind them until there is no obvious After the large particles are sieved, the mesh should be ≥ 40 mesh, dry and store for later use;

[0071] S2: Put the crude tea extract, chitosan oligosaccharide, tartaric acid and sodium carbonate used in S1 into a freeze dryer for 24 hours to dry. In order to ensure the stability of the paste during storage, the samples used should be as dry as possible;

[0072] S3: 150 parts of glycerin and 100 parts of Tween were mixed and prepared; the mixture was homogenized at 6000 rpm for 4 minutes to prepare an empty paste carrier;

[0073] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com