Preparation method of antibacterial and mildew-proof cashmere/cellulosic fiber blended knitted fabric

A cellulose fiber, antibacterial and anti-mildew technology, applied in the direction of enzyme/microbial biochemical treatment, fiber treatment, plant fiber, etc., can solve the problems of fabric fiber strength damage, lack of chemical bonding, and limit the application of chitosan, etc., to achieve The steric hindrance is small, the grafting amount is increased, and the treatment process is green and environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

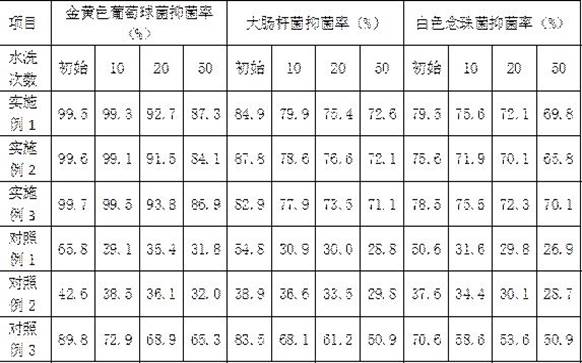

Embodiment 1

[0023] (1) Laccase / TEMPO system catalyzes oxidation of blended knitted fabrics: Cashmere / cellulose fiber blended knitted fabrics are selected from cashmere / cotton fiber blended knitted fabrics, hereinafter referred to as blended knitted fabrics, and the blended knitted fabrics are immersed in 30g / L NaHCO3 solution , heated and maintained at 80°C and stirred for 15 minutes; the blended knitted fabric was taken out and washed until the surface pH was neutral; then the blended knitted fabric was immersed in an acetic acid solution with a mass concentration of 1% for 15 minutes, washed and dried to obtain a pretreated blended knitted fabric; configuration Acetic acid-sodium acetate buffer solution with a pH of 4.6, add TEMPO to make the concentration 10g / L, then add the pretreated blended knitted fabric to infiltrate, then add laccase to make the concentration 100U / mL, blended knitted fabric and laccase / TEMPO The bath ratio of the reaction solution was set to 1:50 (w / v), and the re...

Embodiment 2

[0030] (1) Laccase / TEMPO system catalyzes oxidation of blended knitted fabrics: Cashmere / cellulose fiber blended knitted fabrics are selected from cashmere / cotton fiber blended knitted fabrics, hereinafter referred to as blended knitted fabrics, and the blended knitted fabrics are immersed in 30g / L NaHCO3 solution , heated and maintained at 80°C and stirred for 15 minutes; the blended knitted fabric was taken out and washed until the surface pH was neutral; then the blended knitted fabric was immersed in an acetic acid solution with a mass concentration of 1% for 15 minutes, washed and dried to obtain a pretreated blended knitted fabric; configuration Acetic acid-sodium acetate buffer solution with a pH of 4.6, add TEMPO to make the concentration 10g / L, then add the pretreated blended knitted fabric to infiltrate, then add laccase to make the concentration 250U / mL, blended knitted fabric and laccase / TEMPO The bath ratio of the reaction solution was set to 1:50 (w / v), and the re...

Embodiment 3

[0037] (1) Laccase / TEMPO system catalyzes oxidation of blended knitted fabrics: Cashmere / cellulose fiber blended knitted fabrics are selected from cashmere / cotton fiber blended knitted fabrics, hereinafter referred to as blended knitted fabrics, and the blended knitted fabrics are immersed in 30g / L NaHCO3 solution , heated and maintained at 80°C and stirred for 15 minutes; the blended knitted fabric was taken out and washed until the surface pH was neutral; then the blended knitted fabric was immersed in an acetic acid solution with a mass concentration of 1% for 15 minutes, washed and dried to obtain a pretreated blended knitted fabric; configuration Acetic acid-sodium acetate buffer solution with a pH of 4.6, add TEMPO to make the concentration 20g / L, then add pretreated blended knitted fabric to infiltrate, then add laccase to make the concentration 250U / mL, blended knitted fabric and laccase / TEMPO The bath ratio of the reaction solution was set to 1:50 (w / v), and the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com