Optical touch module based on lattice grating structures in two vector directions

A technology of vector direction and grating structure, which is applied in the coupling of optical waveguide, the input/output process of data processing, instruments, etc., can solve the problems of energy reduction, low efficiency, and affecting touch effect, so as to improve coupling efficiency, Effects of improving output efficiency and reducing waveguide light outcoupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

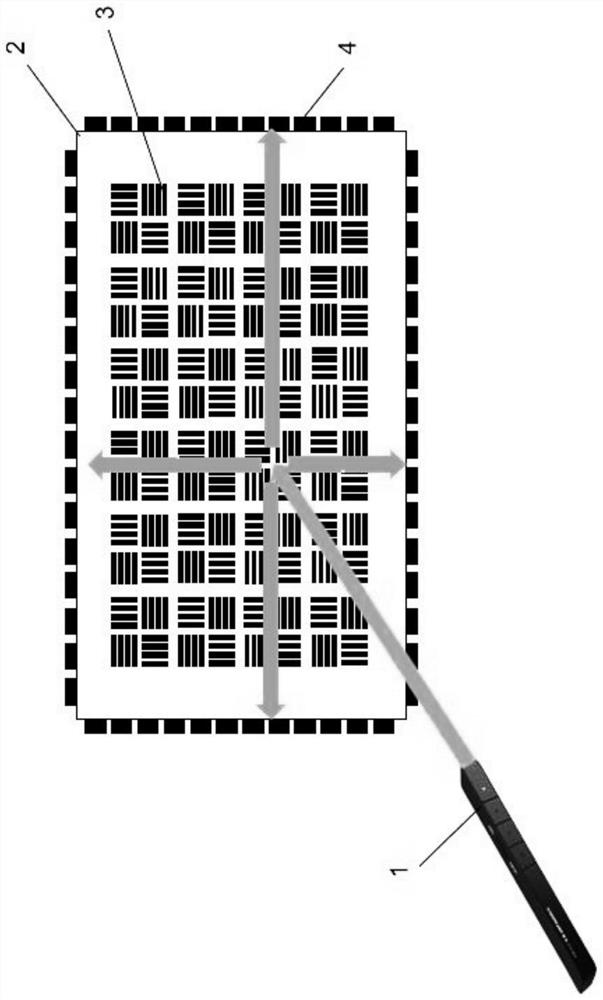

[0049] This embodiment implements an optical touch module based on two types of vector direction lattice grating structures.

[0050] In order to overcome the deficiencies of the prior art, this embodiment is an optical touch module based on two vector direction lattice grating structures, which reduces the thickness of the touch screen, improves the coupling efficiency of incident light and reduces the The transmission loss in the layer, and using the polarization characteristics of the grating, by controlling the grating structure parameters to make the diffraction efficiency of the transverse electric field and transverse magnetic field polarized light relative to the grating unequal, the diffraction efficiency of the coupled light can be improved as much as possible, and the diffraction efficiency of the coupled light can be reduced as much as possible. The outcoupling efficiency of the waveguide light improves the overall output efficiency of the optical touch module.

[...

Embodiment 2

[0070] This embodiment implements an optical touch module based on two types of vector direction lattice grating structures.

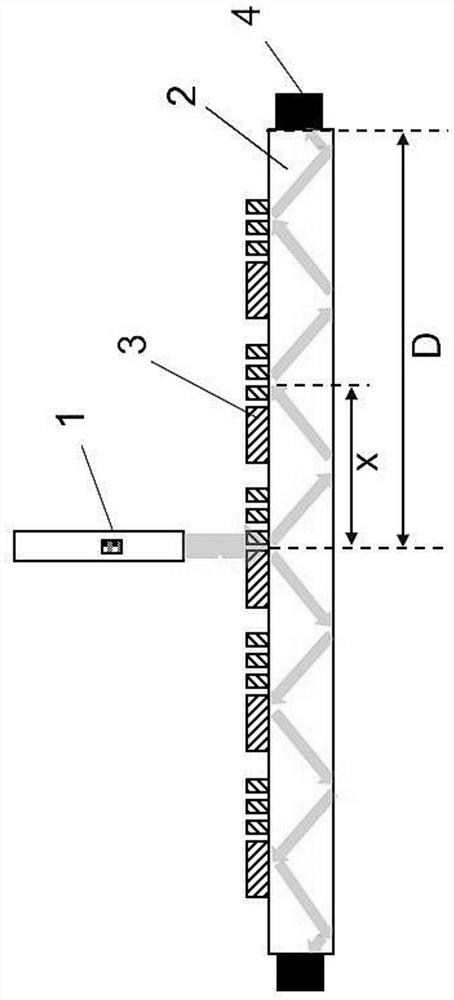

[0071] In this embodiment, an optical touch module based on two kinds of vector direction lattice grating structures is implemented on the basis of Embodiment 1. The laser light source outputs 980nm invisible monochromatic infrared light, and the grating vector directions are x and y. Two directions, two kinds of vector direction lattice gratings are distributed in cross-duty ratio, covering the entire waveguide light-guiding layer, the grating period is 700nm single period, the material of the grating and waveguide light-guiding layer is transparent PC, the refractive index is 1.62, The duty cycle of the grating is 0.5, the height of the grating is 500nm, and the thickness of the waveguide optical layer is 1mm. Figure 14 It is a schematic diagram of the lighttools simulation structure of Embodiment 2 of an optical touch module based on two kinds of v...

Embodiment 3

[0076] This embodiment implements an optical touch module based on two types of vector direction lattice grating structures.

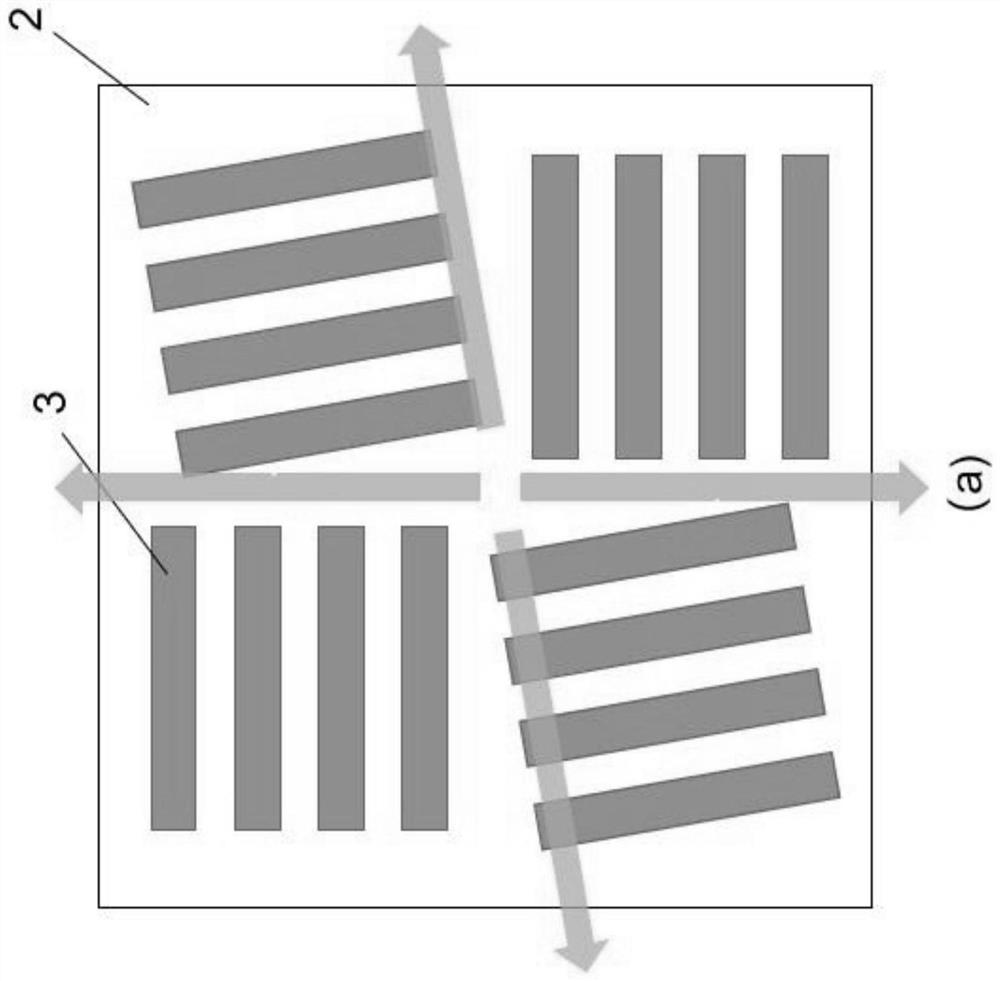

[0077] In this embodiment, an optical touch module based on two kinds of vector direction lattice grating structures is implemented on the basis of Embodiment 1. Figure 15 It is a schematic diagram of two kinds of vector direction lattice grating structures based on the multi-period grating combination of embodiment 3 of an optical touch module based on two kinds of vector direction lattice grating structures. as attached Figure 15 As shown, this embodiment is an optical touch module based on two kinds of vector direction lattice grating structure, the laser light source output is 532nm monochromatic green light, the grating vector direction is two directions of x and y, two sets of direction grating Equal proportions are distributed across the entire waveguide light-guiding layer. The two vector direction lattice gratings are a combination of multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com