High-speed high-response photoelectric detector and manufacturing method thereof

A technology of photodetector and manufacturing method, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as increasing the difficulty of alignment and packaging, difficult testing and packaging, etc., reducing device capacitance, improving device bandwidth, The effect of efficient optical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

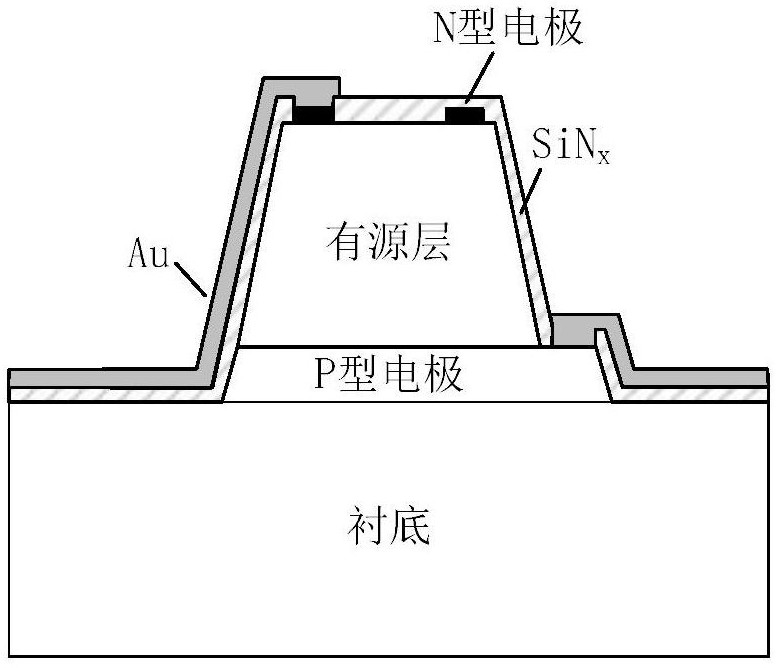

[0033] This embodiment provides a high-speed and high-response photodetector with a structure such as figure 1 As shown, including substrate, P-type electrode, active layer and N-type electrode.

[0034] In the embodiment of the present invention, the substrate is single crystal silicon, the P-type electrode is metal Ti / Pt / Au, and the N-type electrode is metal AuGeNi / Au.

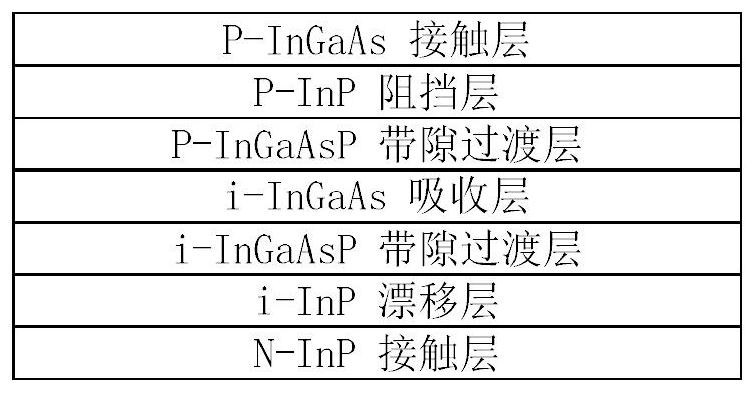

[0035] In the embodiment of the present invention, the active layer of the detector is as follows from bottom to top: P-InGaAs contact layer, P-InP barrier layer, P-InGaAsP band gap transition layer, i-InGaAs absorption layer, i-InGaAsP band gap transition layer , i-InP drift layer and N-InP contact layer.

[0036] Specifically, the i-InGaAs absorption layer has a thickness of 600 nm, and the i-InP drift layer has a thickness of 300 nm.

[0037] In addition, in the embodiment of the present invention, there is a SiNx anti-reflection film on the active layer of the detector with a thickness of 200 nm.

Embodiment 2

[0039] This embodiment provides a method for fabricating a high-speed and high-response photodetector, including the following steps:

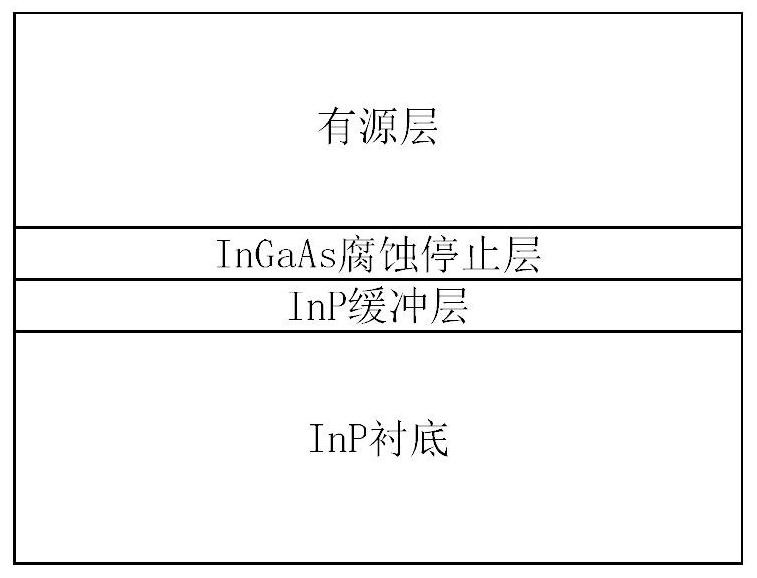

[0040] Step 1, such as figure 2 As shown, an InP buffer layer, an InGaAs etch stop layer and a detector active layer are sequentially grown on an InP substrate, and the detector active layer is as image 3 Shown, from bottom to top are: N-InP contact layer, i-InP drift layer, i-InGaAsP bandgap transition layer, i-InGaAs absorption layer, P-InGaAsP bandgap transition layer, P-InP barrier layer and P -InGaAs contact layer; Specifically, the thickness of the grown InGaAs corrosion stop layer is 500nm, the thickness of the i-InP drift layer is 300nm, and the thickness of the i-InGaAs absorption layer is 600nm;

[0041] Step 2. Evaporate P-type electrode Ti / Pt / Au on the P-InGaAs contact layer, evaporate metal Au on another single crystal silicon wafer, and bond the InP wafer and the silicon substrate wafer together by gold-gold thermocompression ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com