Nano platinum-rare earth alloy as well as preparation method and application thereof

A nano-platinum and nano-technology, applied in the field of electrochemistry, can solve the problems of fixed reduction ability and difficult co-reduction, etc., and achieve the effect of good catalytic activity and stability, uniform size and good crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

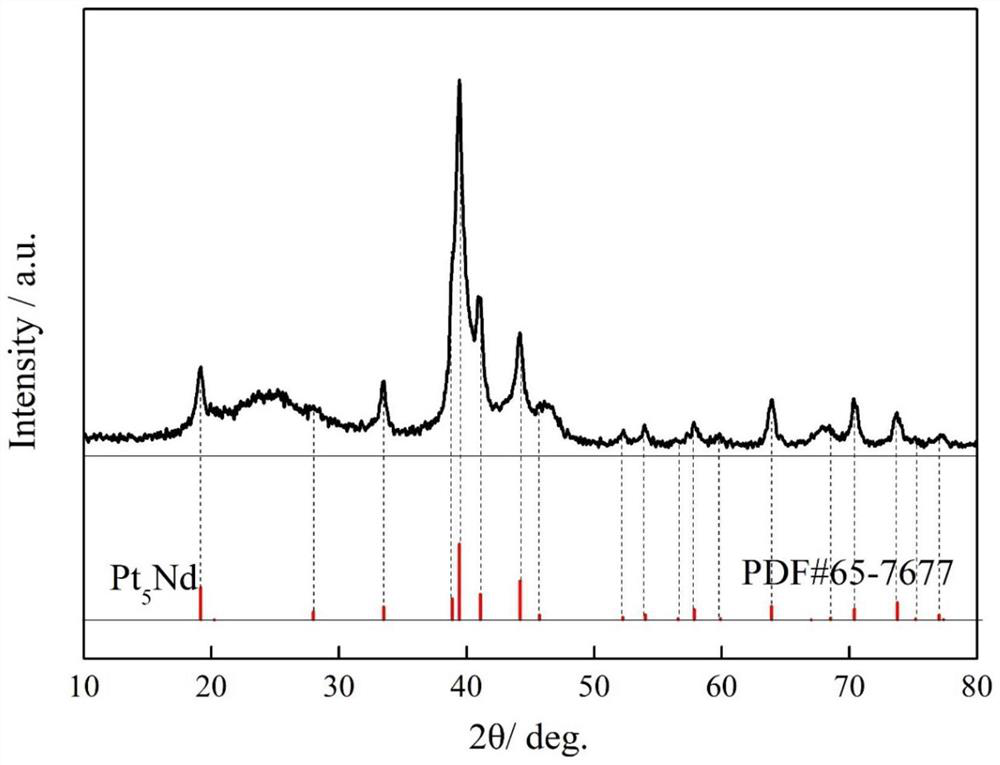

[0051] Example 1: Pt 5 Preparation of Nd / C Nanoalloy

[0052] (1) Preparation of nano-precursor: Weigh carbon black (Vulcan XC-72R) with a mass of 145 mg, 4 The solution (73 mg) was ultrasonically mixed and magnetically stirred for 30 min each. Then Nd(NO 3 ) 3 ·6H 2 O (845mg) and 0.0193mol L -1 H 2 PtCl 6 ·6H 2 O solution 10ml, stirred vigorously for 1h. Ammonia water was added to ensure the pH of the solution was 10, and magnetic stirring was continued for 1 h. Filtrate and wash until the last filtrate is neutral, dry it in vacuum at 80°C, grind it into powder carefully and put it under N 2 Calcined at 700°C for 2 hours in the atmosphere;

[0053] (2) cathode sheet preparation: under 15Mpa pressure, nano-Pt-Nd 2 o 3 / C The powder precursor is pressed into a sheet and connected to a conductor as a cathode;

[0054] (3) Preparation of the electrolysis experiment: The experiment uses a two-electrode system. The distance between electrodes was controlled to be con...

Embodiment 2

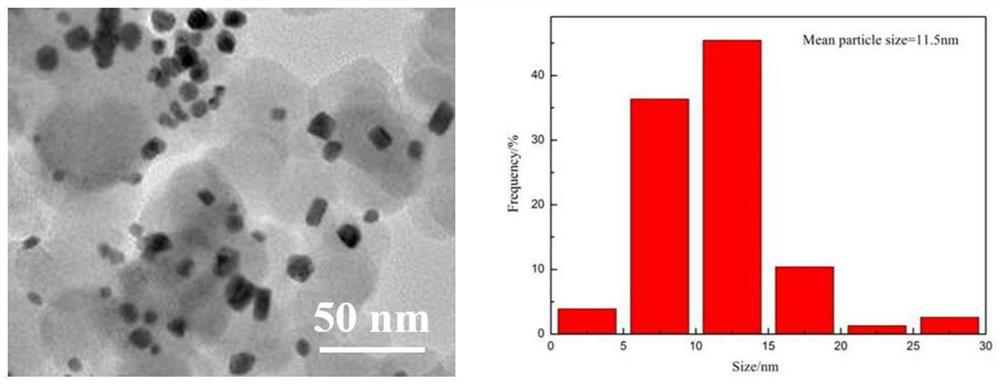

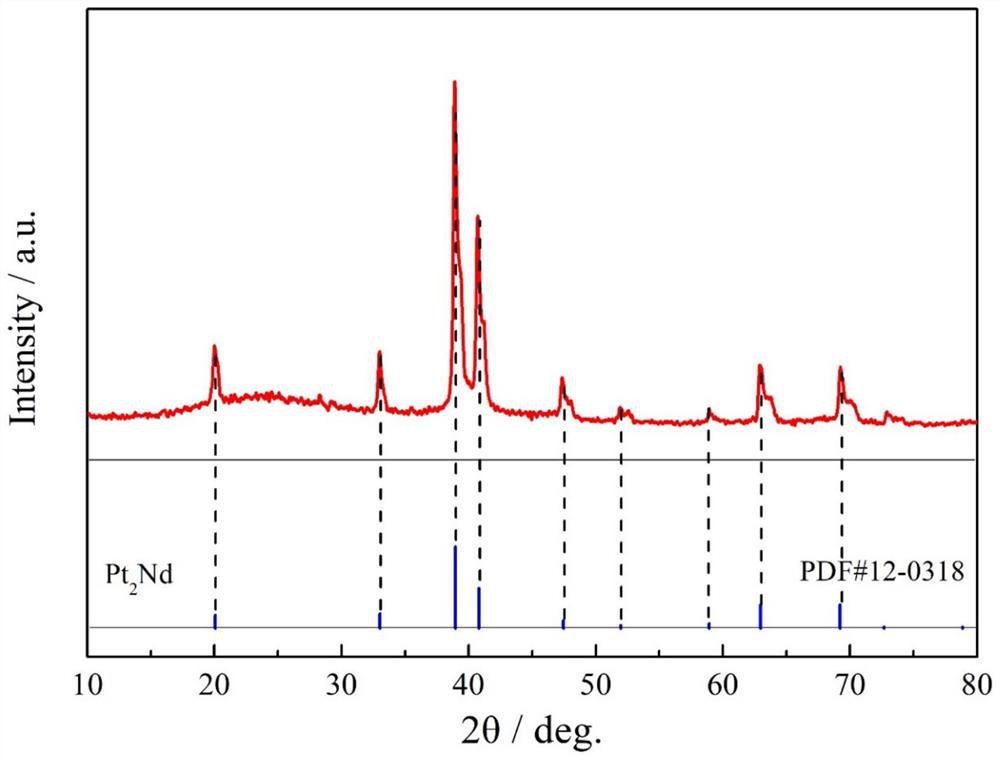

[0058] Example 2: Pt 2 Preparation of Nd / C Nanoalloy

[0059] (1) Preparation of nano-precursor: Weigh 145 mg of carbon black (Ketjen EC 300J) in 100 mL of ethylene glycol (C 2 h 6 o 2 ) in the solution by ultrasonic mixing and magnetic stirring for 30 min each. Then add NdCl to the well mixed slurry 3 (966mg) and 0.0193mol L -1 H 2 PtCl 6 ·6H 2 O solution 10ml, the homogeneously mixed slurry was incubated at 130°C for 3h. Aqueous ammonia was added dropwise to adjust the pH of the slurry to 11, and the stirring was continued for 1 h. Filtrate and wash until the last filtrate is neutral, dry it in vacuum at 90°C, grind it into powder carefully and put it under N 2 Calcined at 500°C for 4h in the atmosphere;

[0060] (2) cathode sheet preparation: under 10Mpa pressure, nano-Pt-Nd 2 o 3 The / C powder precursor is pressed into a cylindrical sheet and connected to a conductor as a cathode;

[0061] (3) Preparation of the electrolysis experiment: The experiment uses a ...

Embodiment 3

[0065] Example 3: Pt 3 Preparation of Dy / C Nanoalloy

[0066] (1) Preparation of nano-precursor: Weigh ordered mesoporous carbon (CMK-5) with a mass of 192 mg, 4 The solution (37 mg) was ultrasonically mixed and magnetically stirred for 30 min each. Then Dy(NO 3 ) 3 ·6H 2 O (88.1mg) and 0.0193mol L -1 H 2 PtCl 6 ·6H 2 O solution 10ml, stirred vigorously for 1h. Ammonia water was added to ensure the pH of the solution was 9, and magnetic stirring was continued for 1 h. Filtrate and wash until the last filtrate is neutral, dry it in vacuum at 80°C, grind it into powder carefully and put it under N 2 Calcination at 900°C for 1h in air;

[0067] (2) Preparation of cathode sheet: Pt-Dy under 20Mpa pressure 2 o 3 / C The powder precursor is pressed into a sheet and connected to a conductor as a cathode;

[0068] (3) Preparation of the electrolysis experiment: The experiment uses a two-electrode system. The distance between electrodes was controlled to be consistent in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com