Iron disulfide resin composite material as well as preparation method and application thereof

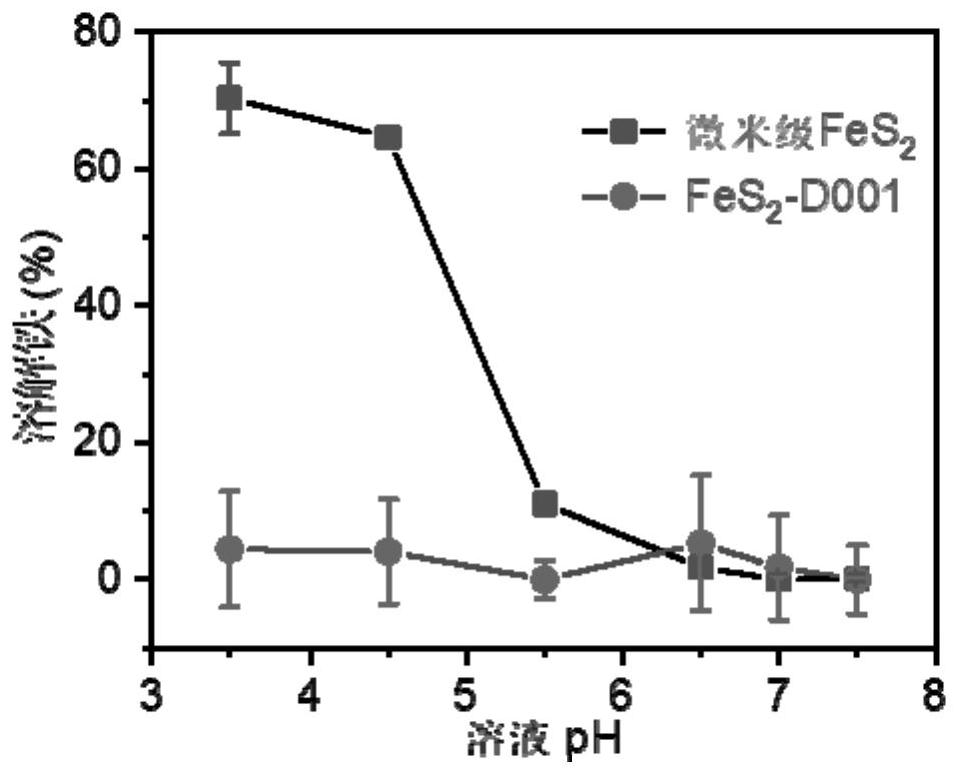

A resin composite material, iron disulfide technology, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problems of high risk of nano-iron disulfide preparation conditions, and achieve easy recycling, The effect of strong selectivity and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

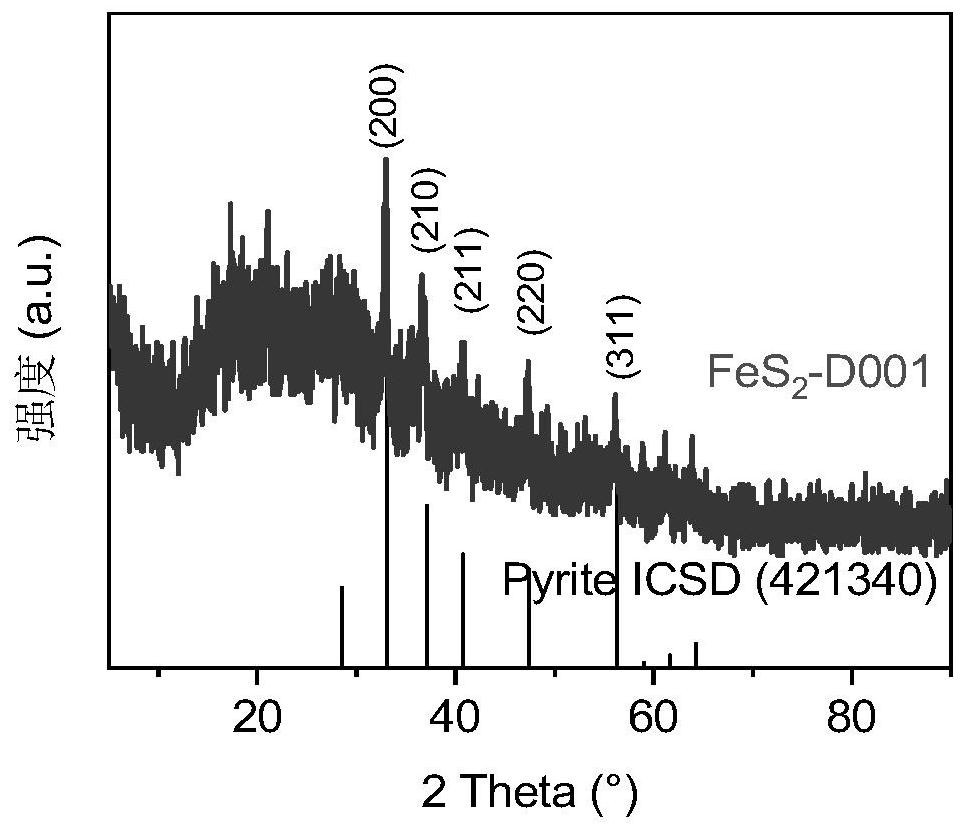

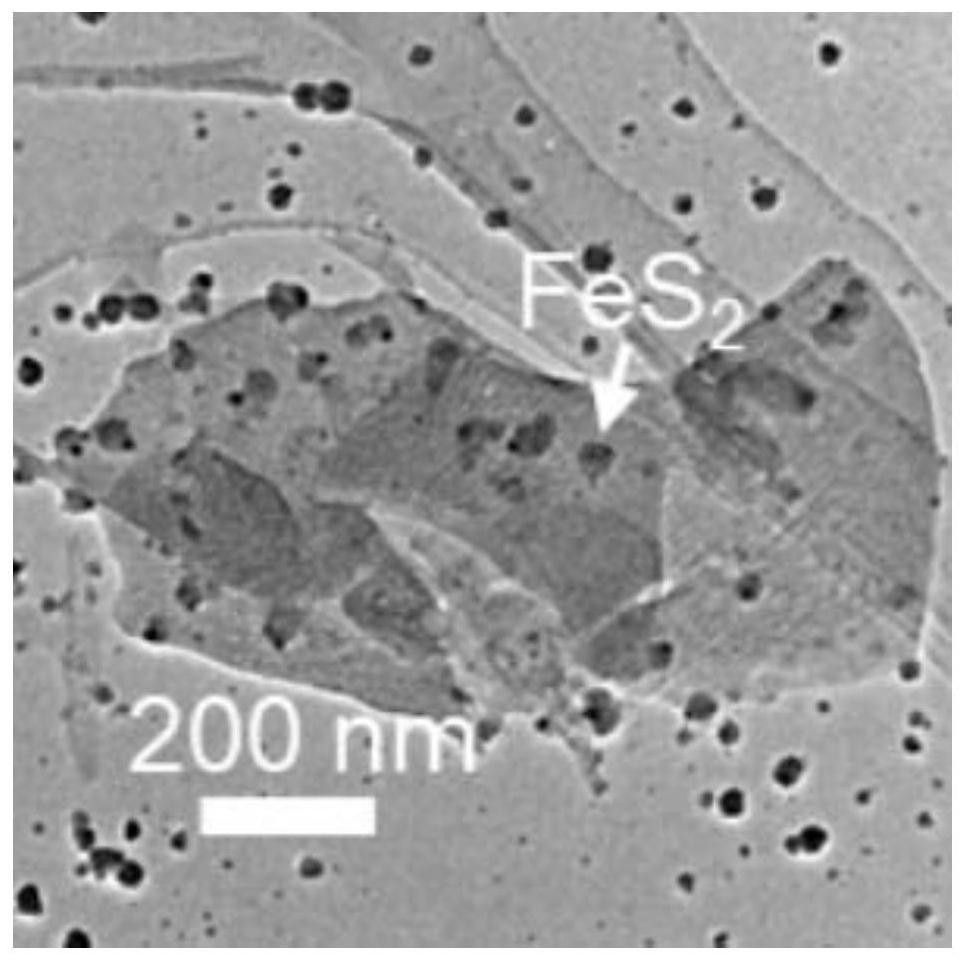

[0054] The present embodiment provides a preparation method of an iron disulfide resin composite material, comprising the following steps:

[0055] 10g of commercial cation exchange resin D001 was rinsed with 100ml of 0.1mol / L hydrochloric acid and 500ml of deionized water, respectively, and extracted with ethanol soxhlet to remove impurities in the resin pores;

[0056] The resin after removal of impurities was placed in 1L containing 0.5mol / LFeCl 3 In the 20% ethanol-water solution of 20%, stirred at room temperature for 24h, then the resin was filtered out and dried at 60°C for 12h;

[0057] Transfer 5g of the dried iron-saturated resin to 0.5mol / L NaHS solution prepared with 0.5L deoxygenated water, adjust the pH of the solution to 4.5 with 0.2mol / L sodium acetate-acetic acid buffer solution, seal the system and place it in a water bath. Incubate at 60°C for 24h;

[0058] The filtered iron disulfide resin was rinsed repeatedly with deionized water until the conductivity ...

Embodiment 2

[0060] The present embodiment provides a preparation method of an iron disulfide resin composite material, comprising the following steps:

[0061] 10g of commercial cation exchange resin 001×7 was rinsed with 200ml of 0.1mol / L hydrochloric acid and 500ml of deionized water, and extracted with ethanol soxhlet to remove impurities in the resin pores;

[0062] The resin after removal of impurities was placed in 0.5L containing 0.3mol / LFe 2 (SO 4 ) 3 50% ethanol-aqueous solution, stirred at room temperature for 18 h, then filtered out the resin and dried at 70 °C;

[0063] Transfer 5g of dried iron-saturated resin to 0.3mol / L NH prepared by 0.5L deoxygenated water 4 In the HS solution, adjust the pH of the solution to 4.5 with 0.1mol / L disodium hydrogen phosphate-citric acid buffer solution, seal the system, and place it in a water bath at 70°C for 12h;

[0064] The filtered iron disulfide resin was rinsed repeatedly with deionized water until the conductivity of the filtrate...

Embodiment 3

[0066] The present embodiment provides a preparation method of an iron disulfide resin composite material, comprising the following steps:

[0067] 10g of commercial cation exchange resin IR120 was rinsed with 200ml of 0.1mol / L hydrochloric acid and 500ml of deionized water, and extracted with ethanol soxhlet to remove impurities in the resin pores;

[0068] The resin after removal of impurities was placed in 0.1L containing 0.1mol / LFe (NO 3 ) 3 20% ethanol-aqueous solution, stirred at room temperature for 24 h, then filtered out the resin and dried at 80 °C;

[0069] Transfer 5g of dried iron-saturated resin to 0.1mol / L NaHS solution prepared with 0.05L deoxygenated water, adjust the pH of the solution to 4.0 with 0.1mol / L citric acid-sodium citrate buffer solution, and place it in a closed system. Keep in a water bath at 70°C for 12h;

[0070] The filtered iron disulfide resin was rinsed repeatedly with deionized water until the conductivity of the filtrate did not change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com