Bio-based amphoteric composite water purifying agent as well as preparation method and application thereof

A water purifier, bio-based technology, applied in chemical instruments and methods, plant fibers, textiles and papermaking, etc., can solve the problems of low pollutant selectivity and weak adsorption capacity, and achieve good oil removal effect and easy operation. , the effect of promoting the coalescence of oil droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

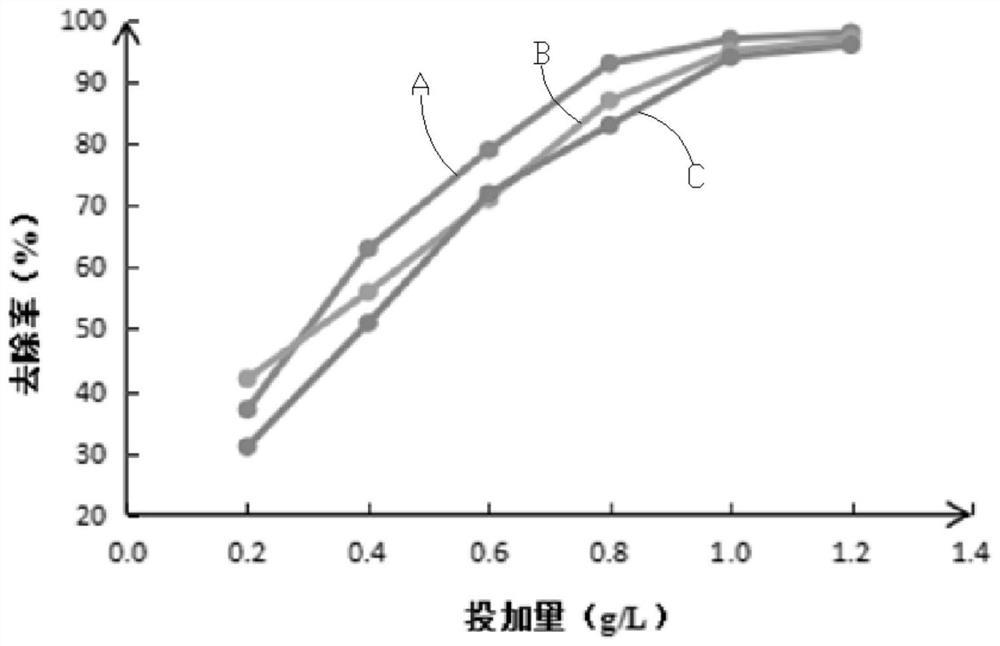

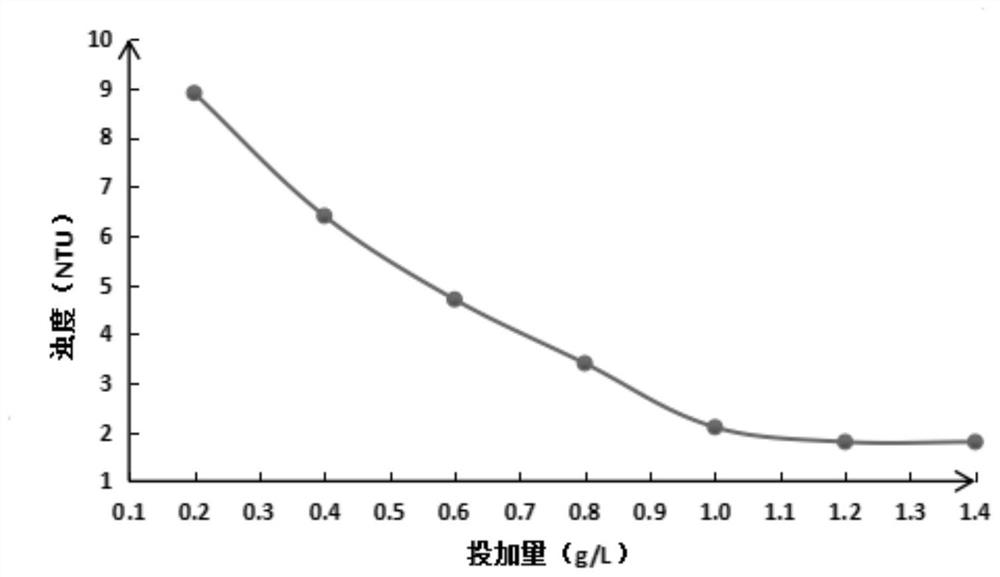

[0041] A bio-based amphoteric composite water purifier is obtained by grafting and modifying kapok fiber with reactive polyamide chitosan thiocarbamate, and the grafting rate is 58%.

[0042] The specific preparation steps of the bio-based amphoteric composite water purifier are:

[0043] S1, Preparation of reactive polyamide chitosan thiocarbamate:

[0044] 1) Carboxymethyl reaction: Suspend 8 g of pulverized chitosan in 100 mL of isopropanol, swell at room temperature for 3 h to obtain a mixture; add 100 mL of 30% NaOH solution dropwise to the above mixture, stir evenly, freeze and alkalize for 8 h , then slowly add 100g of chloroacetic acid solution dropwise, after the dropwise addition, carry out water bath insulation at 50°C for 4h, finally adjust the pH to neutral, wash and dry with ethanol to obtain O-carboxymethyl chitosan;

[0045] 2) Polycondensation reaction: Add the above-mentioned O-carboxymethyl chitosan, organic amine diethylenetriamine, water-carrying agent xy...

Embodiment 2

[0054] A bio-based amphoteric composite water purifier is obtained by grafting and modifying kapok fiber with reactive polyamide chitosan thiocarbamate, and the grafting rate is 65%.

[0055] The specific preparation steps of the bio-based amphoteric composite water purifier are:

[0056] S1, Preparation of reactive polyamide chitosan thiocarbamate:

[0057] 1) Carboxymethyl reaction: Suspend 8 g of pulverized chitosan in 100 mL of isopropanol, swell at room temperature for 3 h to obtain a mixture; add 100 mL of 30% NaOH solution dropwise to the above mixture, stir evenly, freeze and alkalize for 8 h , then slowly add 100g of chloroacetic acid solution dropwise, after the dropwise addition, carry out water bath insulation at 50°C for 4h, finally adjust the pH to neutral, wash and dry with ethanol to obtain O-carboxymethyl chitosan;

[0058] 2) polycondensation reaction: add the above-mentioned O-carboxymethyl chitosan, organic amine polyethylene polyamine, water-carrying agen...

Embodiment 3

[0067] A bio-based amphoteric composite water purifier is obtained by grafting and modifying kapok fiber with reactive polyamide chitosan thiocarbamate, and the grafting rate is 40%.

[0068] The specific preparation steps of the bio-based amphoteric composite water purifier are:

[0069] S1, Preparation of reactive polyamide chitosan thiocarbamate:

[0070] 1) Carboxymethyl reaction: Suspend 8 g of pulverized chitosan in 100 mL of isopropanol, swell at room temperature for 3 h to obtain a mixture; add 100 mL of 30% NaOH solution dropwise to the above mixture, stir evenly, freeze and alkalize for 8 h , then slowly add 100g of chloroacetic acid solution dropwise, after the dropwise addition, carry out water bath insulation at 50°C for 4h, finally adjust the pH to neutral, wash and dry with ethanol to obtain O-carboxymethyl chitosan;

[0071] 2) polycondensation reaction: add the above-mentioned O-carboxymethyl chitosan, organic amine triethylenetetramine, water-carrying agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com