Core-shell structure photonic crystal electrochromic composite film and preparation method thereof

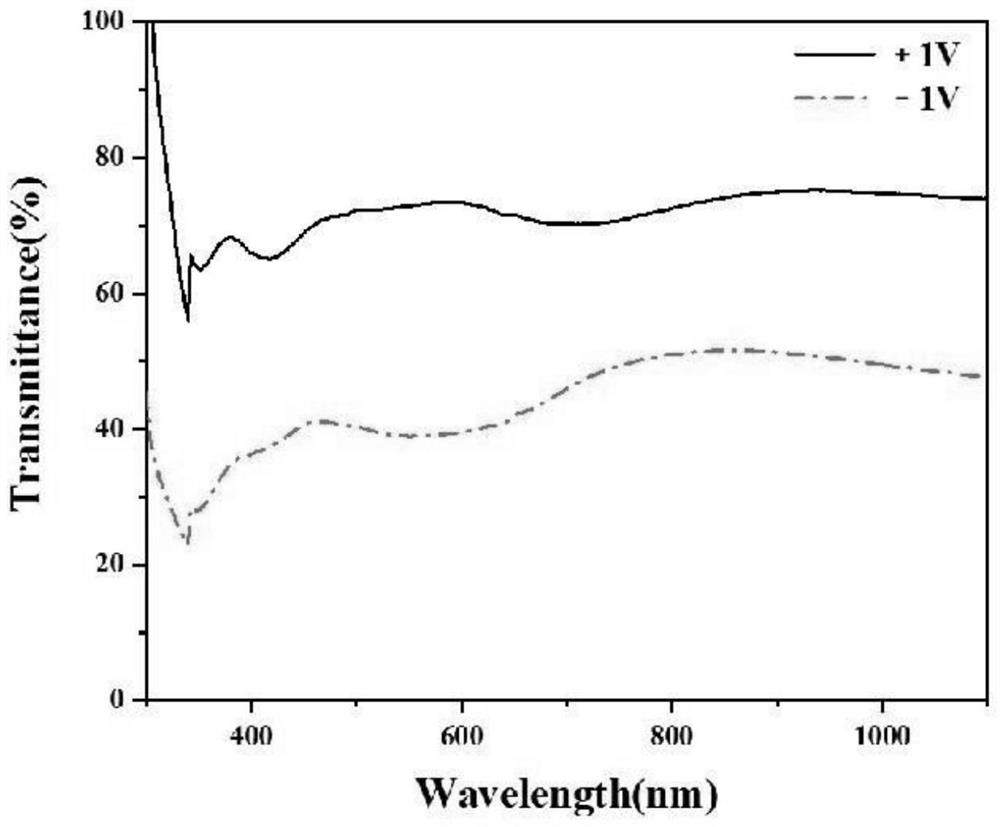

A photonic crystal and electrochromic technology, applied in the coating and other directions, can solve the problems of short life and poor cycle stability of color-changing films, and achieve the effects of low cost, enhanced optical contrast and response rate, and improved conductivity and transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

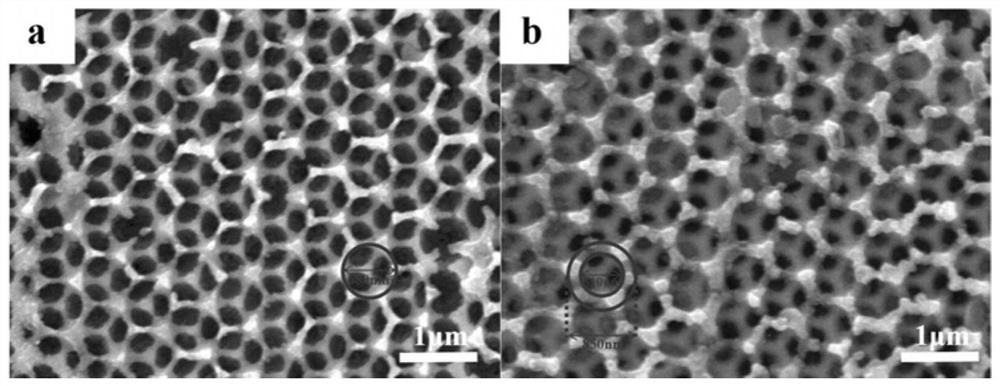

[0033] Step 1: Use the wet-treated FTO glass as the substrate, insert the PS microspheres with a concentration of 0.1wt% vertically at 90°, put them in a 50°C oven for self-assembly until the water evaporates, and obtain a regularly arranged PS colloidal crystal template.

[0034] Step 2: Mix 1.06g sodium tungstate dihydrate, 0.6ml hydrogen peroxide, 16.6ml perchloric acid and 0.22g structure directing agent with 240ml deionized water to prepare WO 3 Precursor, ultrasonically stirred for 18 minutes to obtain the desired electrolyte.

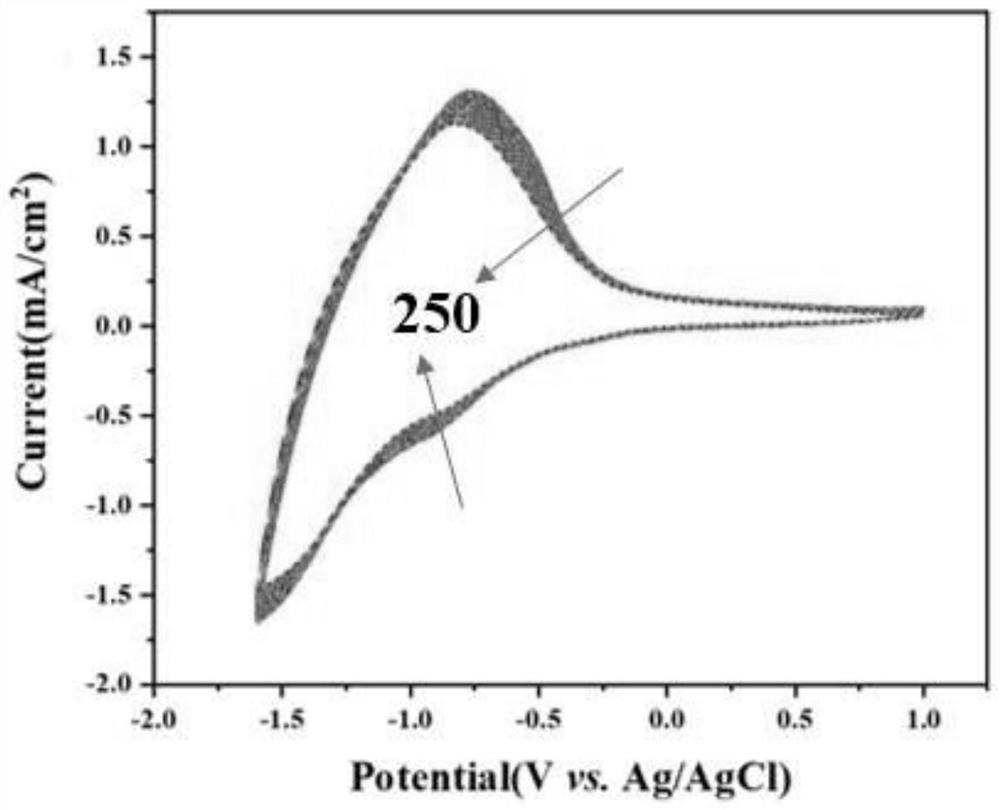

[0035] Step 3, using the PS colloidal crystal template prepared in step 1 as the working electrode, silver / silver chloride as the reference electrode, and platinum sheet as the counter electrode in a three-electrode system to deposit WO in the voids of PS microspheres 3 , Electrodeposition for 300s. After filling, wash 4 times with ethanol and deionized water respectively, N 2 WO obtained after drying in air 3 / PS photonic crystal thin film. ...

Embodiment 2

[0045] Step 1: Use the wet-treated FTO glass as the substrate, insert the PS microspheres with a concentration of 0.14wt% vertically at 90°, put them in a 53°C oven for self-assembly until the water evaporates, and obtain a regularly arranged PS colloidal crystal template.

[0046] Step 2: Mix 1.05g sodium tungstate dihydrate, 0.6ml hydrogen peroxide, 16.7ml perchloric acid and 0.23g structure directing agent with 260ml deionized water to prepare WO 3 Precursor, ultrasonically stirred for 20 minutes to obtain the required electrolyte.

[0047] Step 3, using the PS colloidal crystal template prepared in (1) as the working electrode, silver / silver chloride as the reference electrode, and platinum sheet as the counter electrode in a three-electrode system to deposit WO in the voids of PS microspheres 3 , electrodeposition 270s. After filling, wash 5 times with ethanol and deionized water respectively, N 2 WO obtained after drying in air 3 / PS photonic crystal thin film.

[00...

Embodiment 3

[0052] Step 1: Use the wet-treated FTO glass as the substrate, insert PS microspheres with a concentration of 0.13wt% vertically at 90°, put them in a 55°C oven for self-assembly until the water evaporates, and obtain regularly arranged PS colloidal crystal templates.

[0053] Step 2: Mix 1g of sodium tungstate dihydrate, 0.65ml of hydrogen peroxide, 16.8ml of perchloric acid and 0.23g of structure-directing agent with 260ml of deionized water to prepare WO 3 Precursor, ultrasonically stirred for 25 minutes to obtain the required electrolyte.

[0054] Step 3, using the PS colloidal crystal template prepared in (1) as the working electrode, silver / silver chloride as the reference electrode, and platinum sheet as the counter electrode in a three-electrode system to deposit WO in the voids of PS microspheres 3 , electrodeposition 320s. After filling, wash 4 times with ethanol and deionized water respectively, N 2 WO obtained after drying in air 3 / PS photonic crystal thin film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com