Method for producing furfural from hemicellulose

A technology of hemicellulose and furfural, which is applied in the field of chemical synthesis, can solve the problems of high reuse cost, complicated preparation process, and increased production cost, and achieve the effect of reducing solid residue and increasing the yield of furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

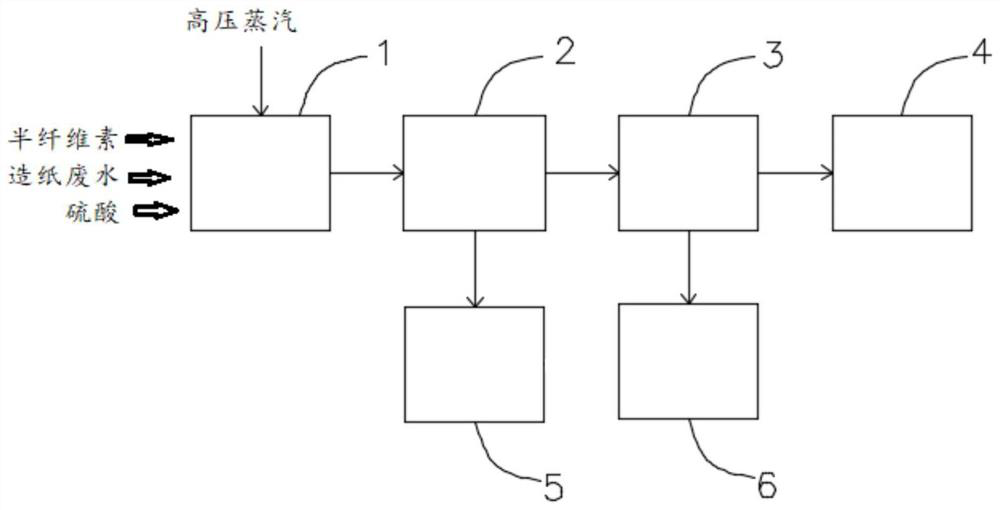

[0031] Present embodiment provides a kind of device that produces furfural by hemicellulose, as figure 1 As shown, the device comprises: reactor 1, liquid separator 2, rectifying tower 3 and finished product tank 4;

[0032] The top of the reactor is provided with a solid feed port for adding hemicellulose, a liquid feed port for adding papermaking wastewater and sulfuric acid, and a high-pressure steam inlet for feeding high-pressure steam; the reactor 1 The bottom of the tank is communicated with the top of the separatory kettle 2;

[0033] The bottom of the liquid separator 2 is communicated with the rectification tower 3;

[0034] The rectification tower 3 communicates with the product tank 4 .

[0035] The separatory tank can also be connected to the waste water recovery tank 5 as required. The rectification tower 3 can also communicate with a residue recovery tank 6 .

[0036] The above-mentioned reactor is provided with a pressure gauge; the rectifying tower is prov...

Embodiment 2

[0038] The present embodiment provides a kind of method that is produced furfural by hemicellulose, uses the device of embodiment 1 to produce, as figure 1 shown, including the following steps:

[0039] Hemicellulose, papermaking wastewater (the main components are water, cellulose, hemicellulose, lignin, soluble salt, xylooligosaccharides and xylose, etc., with a solid content of 5-7%), sulfuric acid (mass fraction of 50 %) into the reaction kettle 1 according to the mass ratio of 1:0.05:0.5, feed high-pressure steam to react, the reaction temperature is 175°C, the reaction pressure is 0.7MPa, and the reaction time is 3h; after the reaction, open the aldehyde valve , obtain gross aldehyde through condensation;

[0040] The gross aldehyde is passed into the separatory kettle 2 containing toluene solution, and the amount of toluene is 50% of the weight of papermaking wastewater. Separation, take the toluene phase of the upper layer; the waste water phase of the lower layer is...

Embodiment 3

[0043] The present embodiment provides a kind of method that is produced furfural by hemicellulose, uses the device of embodiment 1 to produce, as figure 1 shown, including the following steps:

[0044] Hemicellulose, papermaking wastewater (the main components are water, cellulose, hemicellulose, lignin, soluble salt, xylooligosaccharides and xylose, etc., with a solid content of 5-7%), sulfuric acid (mass fraction of 50 %) into the reactor 1 according to the mass ratio of 1:0.1:1, feed high-pressure steam to react, the reaction temperature is 180°C, the reaction pressure is 0.9MPa, and the reaction time is 3h; after the reaction, open the aldehyde valve , obtain gross aldehyde through condensation;

[0045] The gross aldehyde is passed into the separatory kettle 2 containing toluene solution, and the amount of toluene is 100% of the weight of papermaking wastewater. Separation, take the toluene phase of the upper layer; the waste water phase of the lower layer is passed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com