Interplanar high-thermal-conductivity composite material and preparation method thereof

A composite material and high thermal conductivity filler technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of destroying the array orientation structure, unable to achieve full infiltration of fillers, etc., and achieve the effect of high thermal conductivity and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

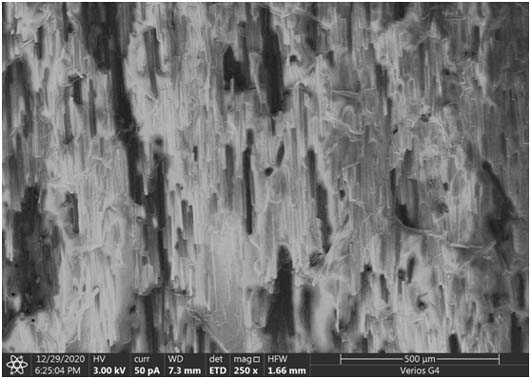

Image

Examples

example 1-4

[0031] (1) Six-water chloride, terephthalic acid, dimethylformamide, vinylsilane, carbon fiber, press 1 mmol: 1 mmol: 10 ml: 0.01 g: 1 g, stirred thoroughly until completely mixed Uniform;

[0032] (2) Transfer the mixture obtained in step (1) to the hydrothermal reaction kettle, reacting 5 h at 125 ° C, filtered, washed, dried, and obtained carbon fibers modified by metal organic frame after drying;

[0033] (3) The carbon fibers obtained in step (2) were calcined at 500 ° C under an inert gas protection for 2 h to obtain magnetic carbon fibers.

[0034] (4) Liquid silicone rubber with a certain amount of magnetic carbon fiber with a viscosity of 300 mPa · s (with methyl vinyl hydrogen: hydrogen-containing silicone oil: platinum catalyst: inhibitor = 100: 10: 1: 0.015 The mixture is mixed than silicon hydrocarbon hydroformation, pouring into the polytetrafluoride mold, and then transferred in a parallel magnetic field having a magnetic field intensity of 3 t, and the magnetic fie...

Embodiment 5

[0037] (1) Six water-chloride, terephthalic acid, dimethylformamide, silane coupling agent, carbon fiber according to 1 mmol: 1 mmol: 10 ml: 0.01 g: 1 g, and stir well until complete The mixing is uniform; wherein the silane coupling agent is composed of a percentage 3: 7 of the aminosilane and the methacryloxysilane.

[0038] (2) Transfer the mixture obtained in step (1) to a hydrothermal reaction kettle, reacted at 100 ° C 10 h, filtered, washed, dried, and obtained carbon fibers modified by metal organic frame after drying.

[0039] (3) The carbon fibers obtained in step (2) are calcined at 1000 ° C under the protection of inert gas to obtain magnetic carbon fibers.

[0040] (4) Liquid silicone rubber (methylvinyl silicone: hydrogen-containing silicone oil) with 30% by weight of magnetic carbon fiber (methylvinyl hydrogen: hydrogen-containing silicone oil: platinum catalyst: inhibitor = 100: 50: 5: 0.005 Will mix evenly, poured into the polytetrafluoride mold, and then transfer...

example 6-9

[0042] (1) Nickel sulfate, 2-methylimidazole, dimethylacetamide, amino silane, and hexagonal boron, boron, boron, boron, 1 mmol: 1 mmol: 20 ml: 0.005 g: 1 g, and stirred with stirring until complete well mixed;

[0043] (2) Transfer the resulting mixture from step (1) to the hydrothermal reaction kettle, at 150 ° C for 10 h, filtered, washed, dried, and obtained hexagonal boron tanks modified by metal organic frame after drying.

[0044] (3) The hexagonal boron obtained in step (2) is calcined with 800 ° C under an inert gas protection for 3 h, and magnetic hexagonal boron is obtained.

[0045] (4) Liquid silicone rubber (methylvinyl silicone: hydrogen-containing silicone oil) with a certain amount of magnetic hexagonal boron and viscosity is 500 mPa · s: Platinum catalyst: inhibitor = 100: 15: 4: 0.05 Number matching reactive reactive reactions) mixed uniform, poured into the polytetrafluoride mold, and then transferred into a parallel magnetic field of 5 t in the magnetic field ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com