Road marking coating suitable for heavy traffic highway and preparation method of road marking coating

A technology for road markings and expressways, which is applied in the field of road marking paint and its preparation for heavy-duty traffic expressways. Anti-friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

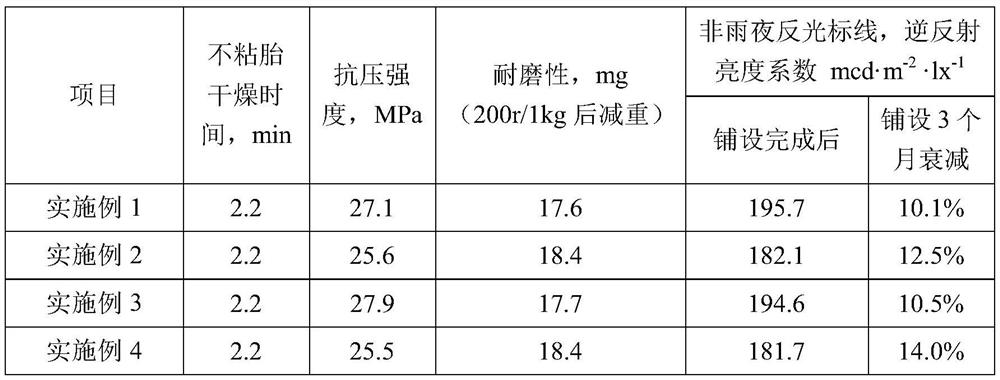

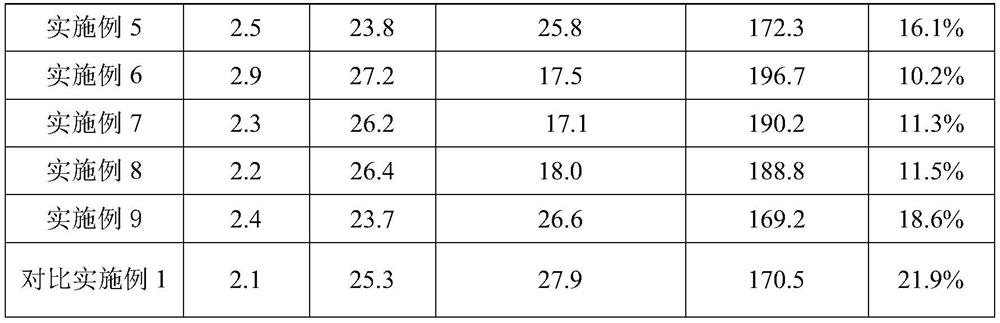

Examples

preparation example 1

[0040] A mixture of 50 parts of C5 resin, 50 parts of C9 resin, 100 parts of SBS, 1 part of 2,3-epoxypropyl methacrylate, 0.6 part of dicumyl peroxide was added to a twin screw with an aspect ratio of 44. Extruder, under the conditions of rotating speed of 85r / min, extrusion temperature of 140℃ / 160℃ / 185℃ / 200℃ / 200℃ / 195℃ / 185℃, and die temperature of 180℃, the extrusion granulation can be improved. Sexual petroleum resin.

preparation example 2

[0042] The rest are the same as in Preparation Example 1, except that the amount of 2,3-epoxypropyl methacrylate used is 0.6 part.

[0043] Preparation of functional fillers

preparation example 3

[0045] A mixed solution was prepared with 37wt% formaldehyde solution, melamine, and deionized water at a constant temperature of 80°C. The molar ratio of formaldehyde and melamine in the mixed solution was 4:1. The pH was adjusted to 8 for the first time, stirred for 1 h, and the pH was adjusted to 4 for the second time. , continue to react for 3h, filter, wash with warm water, and dry to obtain melamine formaldehyde resin microspheres with a particle size of 2.6 μm;

[0046] The melamine formaldehyde resin microspheres were ultrasonically dispersed in water to prepare a 6 wt % dispersion, 10 parts of the dispersion were added to a mixture of 600 parts of ethanol and 600 parts of deionized water, and the pH was adjusted to 7 with 25 wt % of concentrated ammonia. Add 600 parts of tetraethyl orthosilicate dropwise at 40min, keep stirring for 5h, finally centrifuge, wash the separated solid with deionized water 3 times, and finally freeze-dry the dried powder in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com