Film coating composition for silicification-free rubber plug, coating liquid for silicification-free rubber plug, preparation method of coating liquid and method for preparing silicification-free rubber plug

A technology of composition and siliconized rubber, which is applied in the field of preparation of coating liquid for siliconized rubber plugs, preparation of siliconized rubber plugs, and coating liquids for siliconized rubber plugs, which can solve the problem of weak adhesion of film materials and problems with film coating Rubber stoppers are hard, difficult to recycle and reuse, etc., to achieve reliable biological safety and biological stability, avoid mutual diffusion and penetration, and protect drug stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

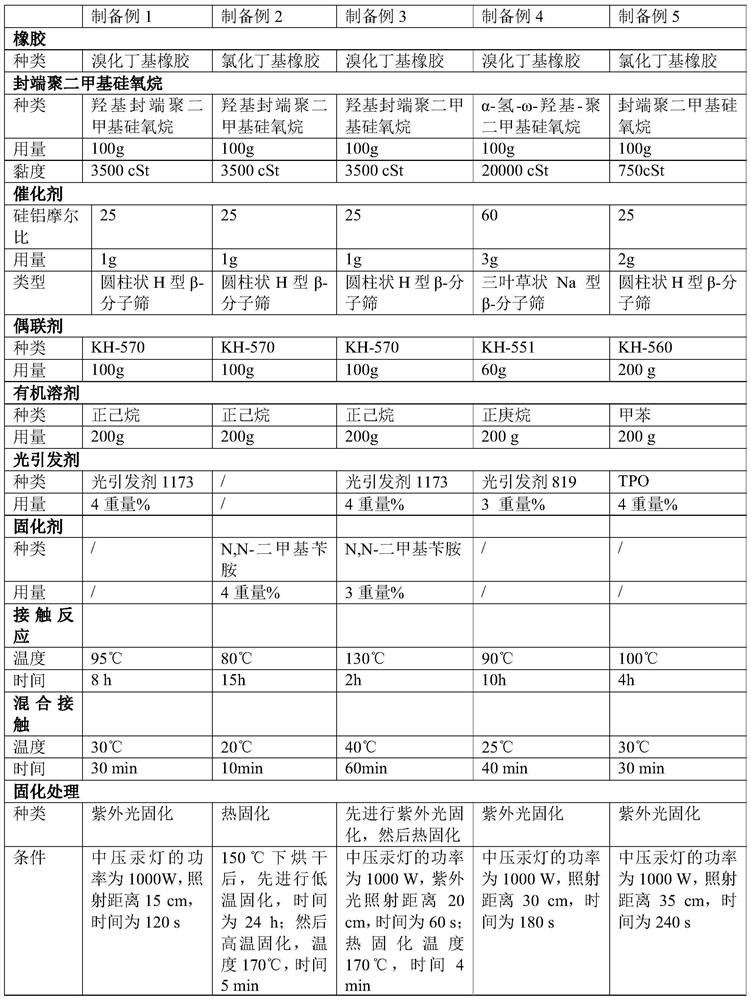

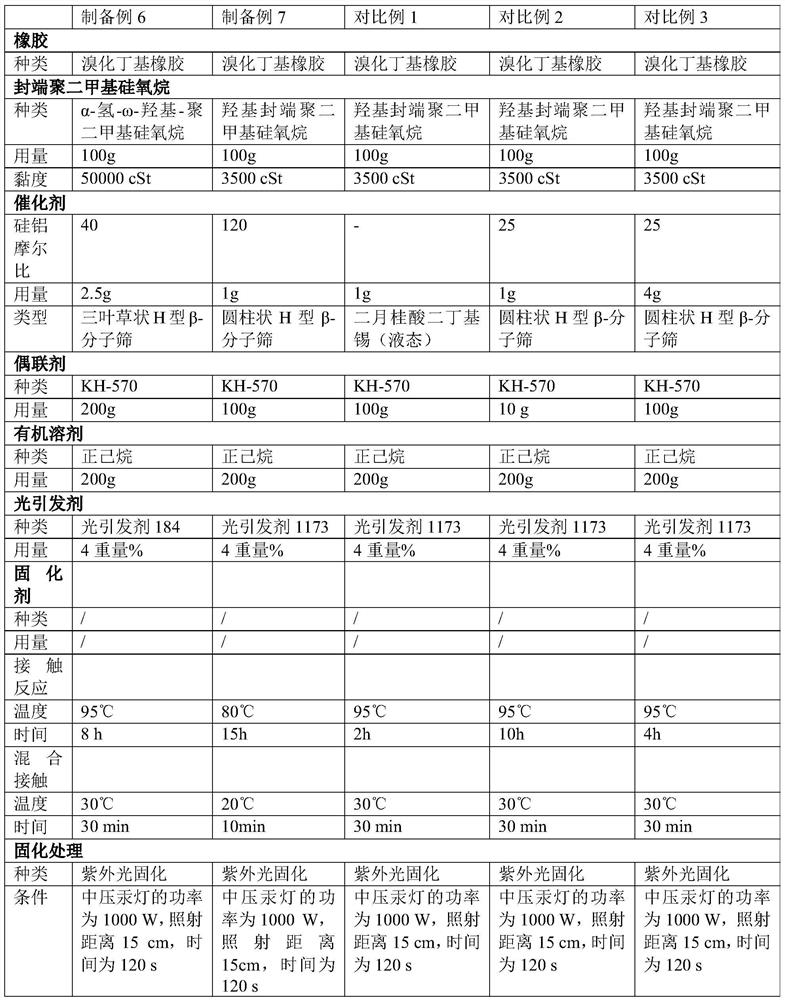

[0033] According to a preferred embodiment of the present invention, the silicon-aluminum molar ratio of the H-type β-molecular sieve catalyst is 20-60. In such an embodiment, the preparation of the coating composition for silicone-free rubber stoppers with the catalyst containing the silicon-aluminum molar ratio is more conducive to the preparation of rubber stoppers with a low surface friction coefficient.

[0034] Preferably, the end-blocked polydimethylsiloxane is selected from amino-blocked polydimethylsiloxane, hydroxyl-blocked polydimethylsiloxane, α-hydrogen-ω-hydroxyl-polydimethylsiloxane at least one of siloxane and alkoxy-terminated polydimethylsiloxane. In the end-capped polydimethylsiloxane of the present invention, the alkoxy group includes a straight-chain alkoxy group, a branched-chain alkoxy group or a cycloalkoxy group, and the total number of carbon atoms in the alkoxy group is 1 -20.

[0035] According to a preferred embodiment of the present invention, t...

specific Embodiment approach

[0058] According to a preferred embodiment of the present invention, the method further includes: before performing the thermal curing, first drying the sprayed rubber plug; preferably, the drying temperature is 100-160°C .

[0059] The thermal curing, for example, can be carried out at a constant temperature, such as curing at a temperature of 100-250°C; it can also be carried out at different temperatures in stages, for example, first curing at 0-90°C, and then curing at 90-250°C Next solidify.

[0060] According to a preferred embodiment of the present invention, the thermal curing includes sequentially performing low-temperature curing at a temperature of 20-40°C and high-temperature curing at a temperature of 150-200°C. In this preferred embodiment, the rubber stopper cured in stages has a lower surface friction coefficient and better UV resistance, chemical resistance and aging resistance.

[0061] Preferably, the low temperature curing time is 12-36 hours, and the hig...

preparation example 1

[0082] The material of the non-siliconization rubber stopper in this embodiment is brominated butyl rubber, including preparing a coating solution from the coating composition, coating the coating solution on the surface of the cleaned and dried rubber stopper and curing the coating. step.

[0083] Among them, the composition of the coating composition is: 100g of hydroxyl-terminated polydimethylsiloxane (viscosity of 3500cSt at 20°C), 1g of H-type β-molecular sieve catalyst (silica-aluminum molar ratio is 25, cylindrical) 1g, Joint agent (KH-570) 100g, organic solvent (n-hexane) 200g.

[0084] The preparation process of the silicone-free rubber plug of the present embodiment, the specific steps are as follows:

[0085] (1) According to the above weight ratio, dissolve the blocked polydimethylsiloxane, coupling agent and catalyst in an organic solvent for contact reaction (contact reaction conditions include: temperature is 95°C, time is 8h), and obtained mixture solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com