Pyrolyzing furnace pyrolysis material discharging device and discharging system

A discharge device, pyrolysis furnace technology, applied in the direction of discharge device, coke oven, coke cooling, etc., can solve the problems of peripheral fire, safety hazards of discharge machine, unable to meet actual needs, etc., to improve heat exchange effect , reduce the cooling water dead zone, increase the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

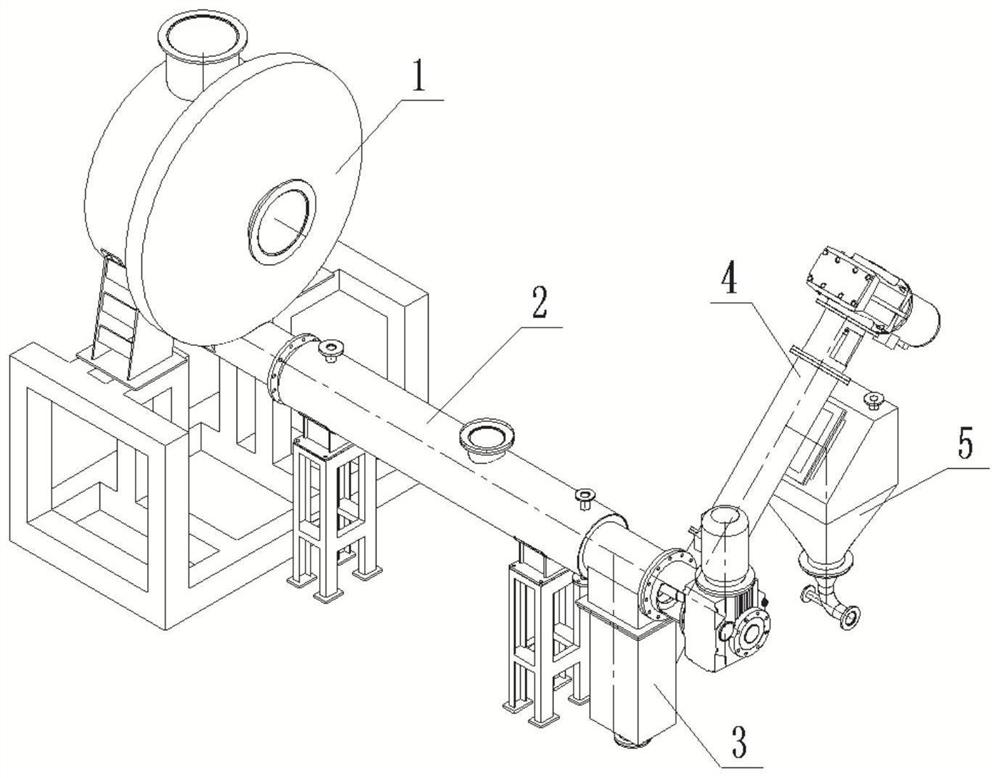

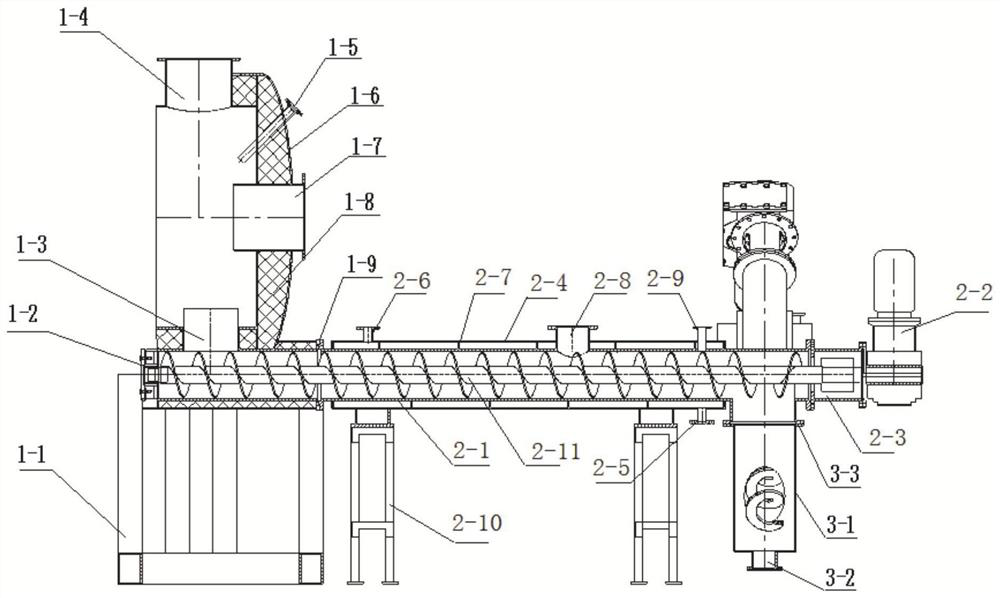

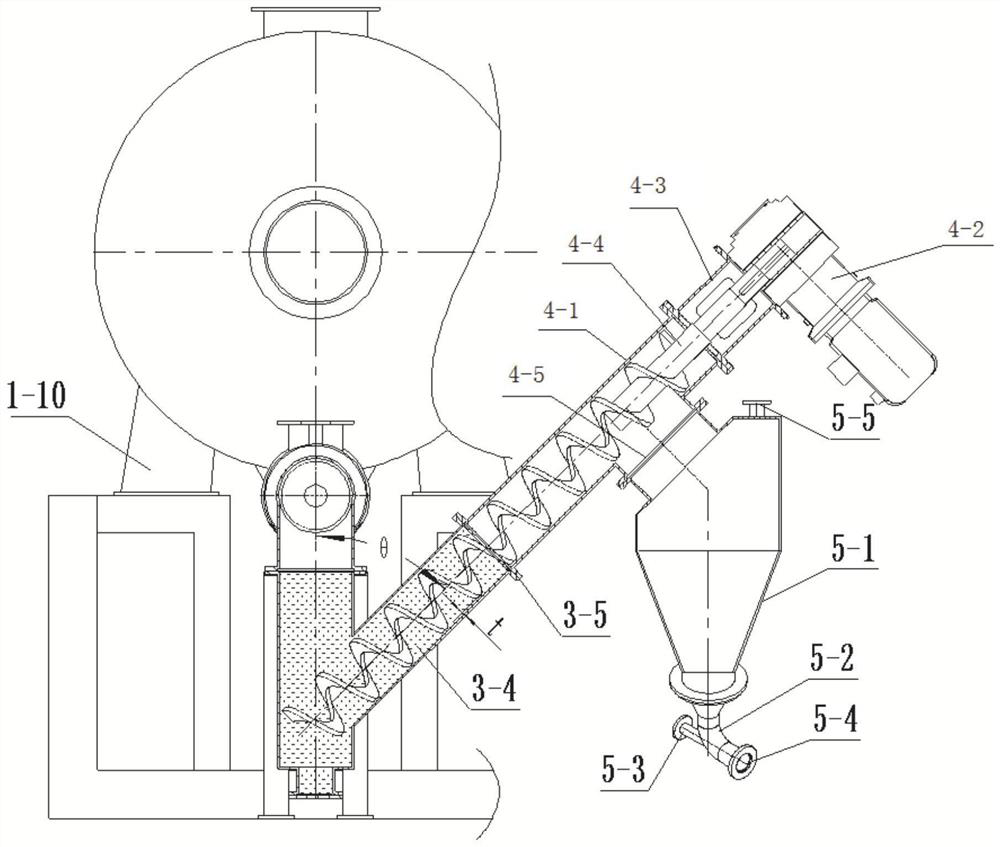

[0033] This embodiment provides a pyrolysis furnace pyrolysis material discharge device, such as Figure 1-Figure 3 As shown, it includes a first screw conveyor 2, a sealed box 3 and a second screw conveyor 4 connected in sequence.

[0034] The first screw conveyor 2 adopts a shaft screw conveyor, including a first shell 2-1, the first shell is supported by a plurality of support frames 2-10, and one end of the first shell 2-1 can It is connected with the pyrolysis furnace discharge end cover shell of the pyrolysis furnace, and the other end of the first shell 2-1 is fixed with a driving element. In order to meet the needs of the working environment, the driving element adopts the first variable frequency explosion-proof motor 2-2 , the output shaft of the first variable frequency explosion-proof motor 2-2 is connected to the first material delivery mechanism through a coupling 2-3, and the first material delivery mechanism includes a main shaft and a helical blade fixed on th...

Embodiment 2

[0052] This embodiment provides a kind of pyrolysis furnace pyrolysis material discharge system, such as Figure 1-Figure 3 As shown, the pyrolysis furnace pyrolysis material discharging device described in embodiment 1 is included.

[0053] The first screw conveyor 2 is connected with the discharge end cover 1 of the pyrolysis furnace, the discharge end cover of the pyrolysis furnace can be connected with the pyrolysis furnace, and the pyrolysis charcoal powder of the pyrolysis furnace can enter the first screw conveyor.

[0054] The discharge end cover of the pyrolysis furnace includes an end cover fixing frame 1-1, and one end of the end cover fixing frame 1-1 is welded and fixed with the end cover bracket 1-10, and the other end of the end cover bracket 1-10 is connected with the heat The discharge end cover housing 1-6 of the pyrolysis furnace is fixed, the discharge end cover housing 1-6 of the pyrolysis furnace is fixed on the end cover fixing frame 1-1, and the first s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com