Negative pole piece capable of improving cycle performance of high-voltage lithium battery and preparation method and application thereof

A technology for negative pole piece and cycle performance, which is applied in the field of negative pole piece and preparation for improving the cycle performance of high-voltage lithium batteries. It can solve problems such as capacity prone to lithium precipitation, large polarization, and short cycle life, and achieve improved capacity. Retention rate, improvement of diffusion resistance, and effect of improving lithium precipitation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

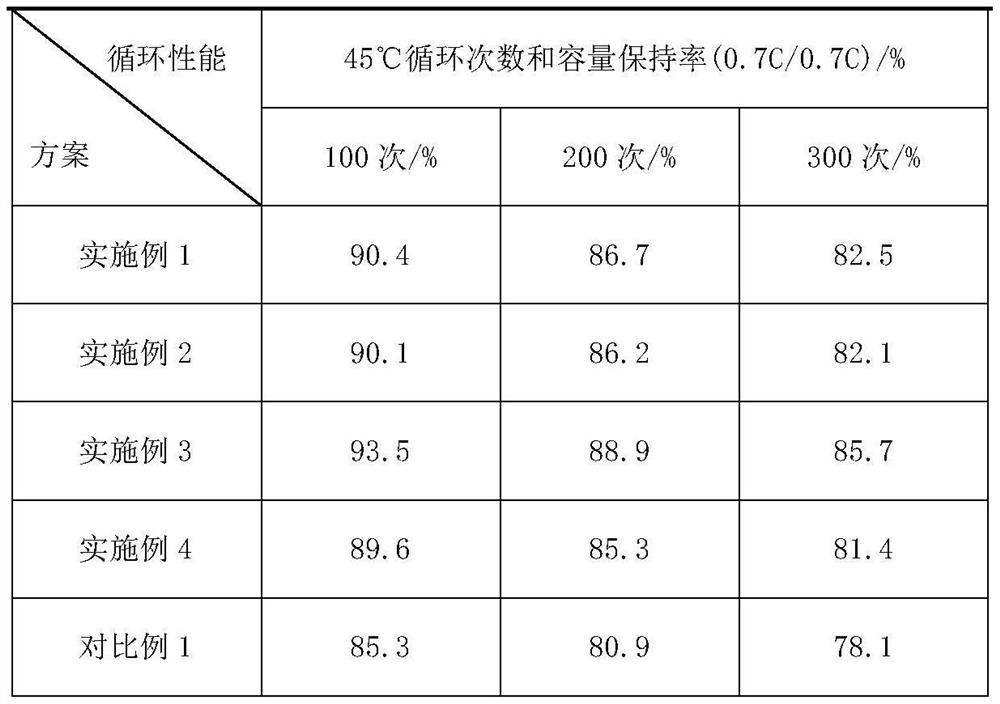

Examples

preparation example Construction

[0027] A method for preparing a negative electrode sheet for improving the cycle performance of a high-voltage lithium battery, comprising the following steps:

[0028] Step 1: Coating coating A on the paste-coated surface of the negative electrode current collector, the slurry of the coating A includes 77.2% to 97.01% silicon carbon negative electrode, 0.48% to 19.5% artificial graphite, 0.5% to 1.0% conductive agent, 1.5% ~ 3.0% binder.

[0029] Step 2: Coating coating B on the short pasted surface of the negative electrode current collector, the slurry of the coating B includes 77.2% to 97.01% silicon carbon negative electrode, 0.48% to 19.5% artificial graphite, 0.5% to 1.0% conductive agent, 1.5% ~ 3.0% binder.

[0030] Preferably, the sum of the mass percentages of silicon carbon negative electrode and artificial graphite in the slurry of coating A is 96.5% to 97.5%; the sum of the mass percentages of silicon carbon negative electrode and artificial graphite in the slur...

Embodiment 1

[0038] A method for preparing a negative electrode sheet for improving the cycle performance of a high-voltage lithium battery, comprising the following steps:

[0039] Step 1: Coating coating A on the paste surface of the negative electrode current collector, the thickness of coating A is 60 μm; the slurry of coating A includes 96% silicon carbon negative electrode, 0.5% artificial graphite, 1.0% by mass percentage % conductive agent (0.1% carbon nanotube + 0.9% conductive carbon black), 2.5% binder (1.2% sodium carboxymethyl cellulose + 1.3% polyacrylic acid); wherein the silicon carbon negative electrode has a gram capacity of 380mAh / g, artificial The gram capacity of graphite is 350mAh / g, and the OI value is 1.0;

[0040]Step 2: Coating coating B on the short pasted surface of the negative electrode current collector, the thickness of coating B is 60 μm; the slurry of coating B includes 96% silicon carbon negative electrode, 0.5% artificial graphite, 1.0% by mass percentag...

Embodiment 2

[0042] A method for preparing a negative electrode sheet for improving the cycle performance of a high-voltage lithium battery, comprising the following steps:

[0043] Step 1: Coating coating A on the long paste surface of the negative electrode collector, the thickness of coating A is 60 μm; the slurry of the coating A includes 96.5% silicon carbon negative electrode, 0.5% artificial graphite, 1.0% by mass percentage % conductive agent (0.1% carbon nanotube + 0.9% conductive carbon black), 2.0% binder (0.9% sodium carboxymethyl cellulose + 1.1% polyacrylic acid); wherein the silicon carbon negative electrode has a gram capacity of 380mAh / g, artificial The gram capacity of graphite is 356mAh / g, and the OI value is 1.5;

[0044] Step 2: Coating coating B on the short pasted surface of the negative electrode current collector, the thickness of coating B is 60 μm; the slurry of coating B includes 96.5% silicon carbon negative electrode, 0.5% artificial graphite, 1.0% by mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com