Magnesium alloy negative electrode plate for seawater battery and preparation method

A seawater battery and magnesium alloy technology, applied in battery electrodes, immersion batteries, circuits, etc., can solve the problems of insufficient discharge activity, serious polarization, and accelerated corrosion speed, and achieve low dislocation density, easy to fall off, and reduce electrical current. The effect of dual corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An embodiment of the present invention provides a method for preparing a magnesium alloy negative electrode plate, the method comprising the following steps:

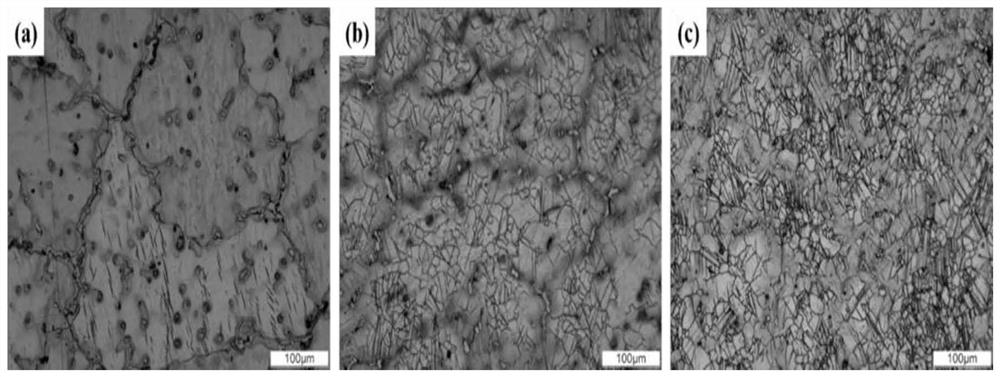

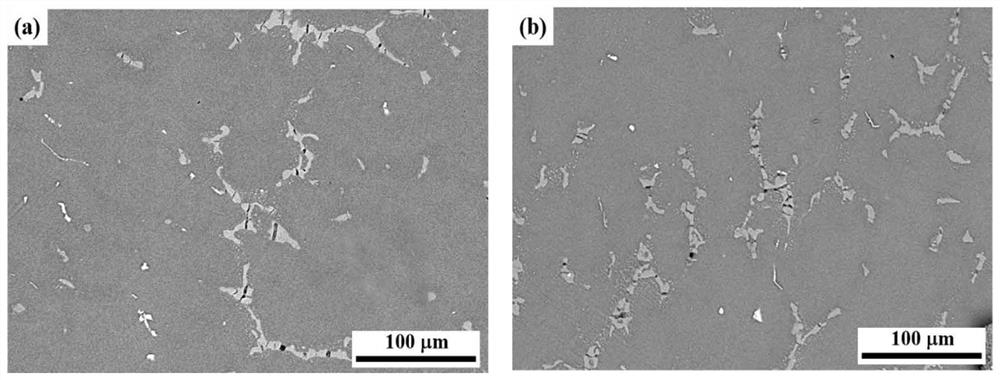

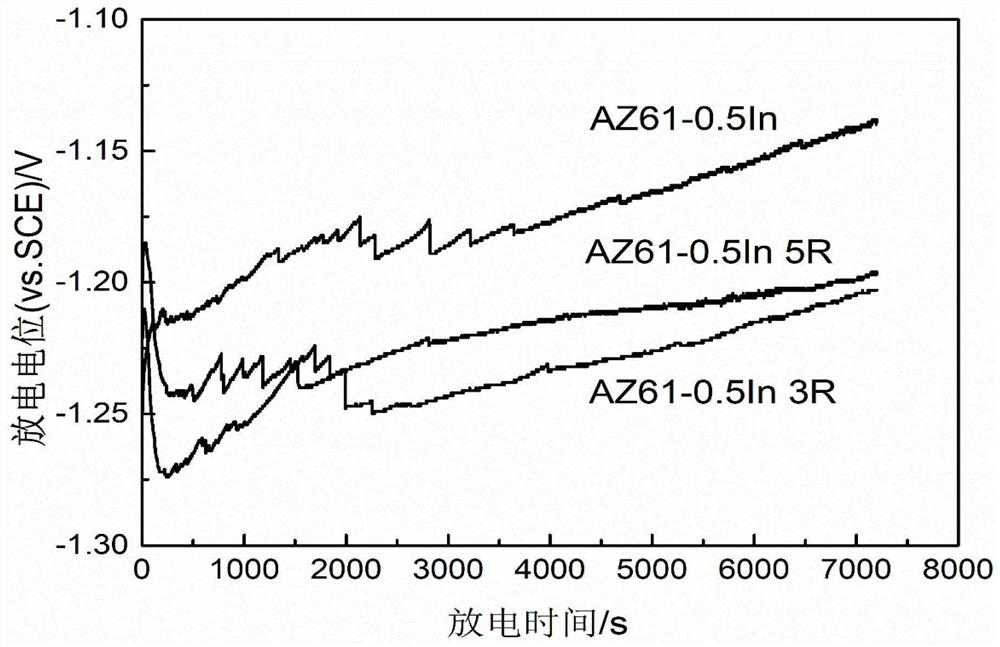

[0028] Taking AZ61 (Mg: 6.1wt.%; Al: 0.93wt.%; Zn: 0.54wt.%; In: 0.2wt.%; Mn: 0.1wt.%), pure Mg (99.95%), pure In (greater than Or equal to 99.99%) as the raw material. Under the mixed atmosphere of CO2 (99vol%) and SF6 (1vol%), the magnesium alloy raw material containing indium element is smelted, specifically, the melting temperature of the magnesium alloy raw material containing indium element is 680°C. The mass percentage of the indium element in the magnesium alloy negative electrode is 0.5%. When the block is completely melted, it is fully stirred for 2 minutes and left to stand for 15 minutes, and then the melt is cast in a steel mold to obtain a block magnesium alloy negative electrode ingot , the magnesium alloy raw material is melted and then cast into shape and water-cooled to obtain a cast magnesium ...

Embodiment 2

[0032] An embodiment of the present invention provides a method for preparing a magnesium alloy negative electrode plate, the method comprising the following steps:

[0033] Taking AZ61 (Mg: 6.1wt.%; Al: 0.93wt.%; Zn: 0.54wt.%; In: 0.2wt.%; Mn: 0.1wt.%), pure Mg (99.95%), pure In (greater than Or equal to 99.99%) as the raw material. in CO 2 (99vol%) and SF 6 (1vol%) under the mixed atmosphere, the magnesium alloy raw material containing indium element is smelted, specifically, the melting temperature of the magnesium alloy raw material containing indium element is 720°C. The mass percentage of the indium element in the magnesium alloy negative electrode is 0.55%. When the block is completely melted, it is fully stirred for 2 minutes and left to stand for 15 minutes, and then the melt is cast in a steel mold to obtain a block magnesium alloy negative electrode ingot , the magnesium alloy raw material is melted and then cast into shape and water-cooled to obtain a cast magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com