High-temperature-resistant composite coating containing rare earth aluminate and preparation method of high-temperature-resistant composite coating

A composite coating and aluminate technology, which is applied in coatings, surface reaction electrolytic coatings, metal material coating processes, etc., can solve the problems of few research reports on the thermal properties of rare earth aluminates, and achieve excellent high temperature resistance Effects of ablation characteristics, excellent thermal insulation performance, and high roughness factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

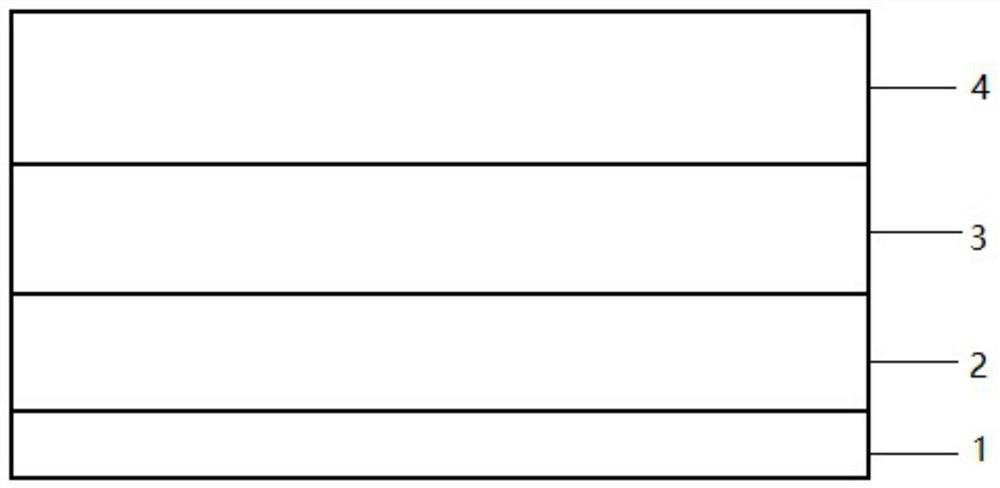

[0047] In another aspect, the present invention provides a method for preparing a high temperature resistant composite coating containing rare earth aluminate, comprising the following steps:

[0048] Step 1: performing micro-arc oxidation treatment on the alloy substrate to obtain a micro-arc oxidation film layer with a film thickness of 10-20 μm;

[0049] Step 2: preparing a layer of metal bonding layer on the micro-arc oxidation film layer;

[0050] Step 3: Using the atmospheric plasma spraying process to deposit the rare earth aluminate spray powder on the surface of the metal bonding layer in step 2 to obtain the atmospheric plasma sprayed rare earth aluminate ceramic layer, and complete the preparation of the high temperature resistant composite coating containing rare earth aluminate .

[0051] Specifically, in the above step 1, the micro-arc oxidation process is as follows: current waveform: one-way pulse or two-way square wave, pulse waveform frequency: 50Hz-1500Hz; ...

Embodiment 1

[0072] This example provides a method for preparing a high-temperature-resistant composite coating containing rare earth aluminates. This method is used to prepare a high-temperature-resistant composite coating containing rare earth aluminates on the surface of an alloy part substrate. The specific details are as follows:

[0073] Step 1: Perform micro-arc oxidation treatment on the alloy part substrate, and the thickness of the film layer is 18 μm;

[0074] The micro-arc oxidation process is: the current waveform is a bidirectional square wave, the pulse waveform frequency is 180Hz; the forward current density is 240A / dm 2 ;Negative current density is 70A / dm 2 ; The positive duty cycle is 35%, the negative duty cycle is 30%; the micro-arc oxidation time is 18 min; the temperature of the micro-arc oxidation bath is 25°C.

[0075] Step 2: using an atmospheric plasma spraying process to prepare a layer of metal bonding layer on the micro-arc oxidation film layer treated in step...

Embodiment 2

[0092] This example provides a method for preparing a high-temperature-resistant composite coating containing rare earth aluminates. This method is used to prepare a high-temperature-resistant composite coating containing rare earth aluminates on the surface of an alloy part substrate. The specific details are as follows:

[0093] Step 1: Perform micro-arc oxidation treatment on the alloy part substrate, and the film thickness is 20 μm;

[0094] The micro-arc oxidation process is: current waveform: bidirectional square wave, pulse waveform frequency 300Hz; forward current density 200A / dm 2 ;The negative current density is 50A / dm 2 ; The positive duty cycle is 35%, and the negative duty cycle is 40%; the micro-arc oxidation time is 18 minutes; the micro-arc oxidation bath temperature: 30°C.

[0095] Step 2: using an atmospheric plasma spraying process to prepare a layer of metal bonding layer on the micro-arc oxidation film layer treated in step 1;

[0096] The composition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com