Water-based coating for electric power equipment and preparation method thereof

A water-based technology for power equipment, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of easy cracking and poor compatibility of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

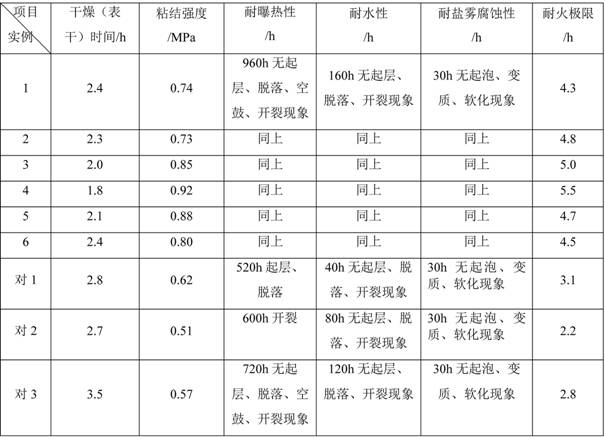

Examples

Embodiment 1

[0027] A water-based paint for electric equipment is made of the following raw materials in parts by weight:

[0028] 25 parts of silicone modified acrylate emulsion, 20 parts of phenolic resin, 15 parts of ammonium polyphosphate, 10 parts of zinc borate, 5 parts of pentaerythritol, 10 parts of diatomaceous earth, 7 parts of expanded perlite, γ-Al 2 o 3 0.1 part, 5 parts of graphene oxide, 1 part of film former, 0.01 part of defoamer and 40 parts of water.

[0029] The preparation method of organosilicon-modified acrylate emulsion comprises the following steps:

[0030] First, mix 0.4 parts of sodium lauryl sulfate, 0.6 parts of OP-10, 0.05 parts of sodium bicarbonate and 25 parts of water, stir for 5 minutes, and then dropwise add 10 parts by weight of octamethylcyclotetrasiloxane, 2 parts of methyl methacrylate and 6 parts of butyl acrylate are dropped within 3 hours, then add 0.6 parts of dodecylbenzenesulfonic acid and 0.4 parts of ammonium persulfate, heat up to 75°C, ...

Embodiment 2

[0043] A water-based paint for electric equipment is made of the following raw materials in parts by weight:

[0044] 28 parts of silicone modified acrylate emulsion, 22 parts of phenolic resin, 18 parts of ammonium polyphosphate, 11 parts of zinc borate, 6 parts of pentaerythritol, 12 parts of diatomaceous earth, 8 parts of expanded perlite, γ-Al 2 o 3 0.2 parts, 6 parts of graphene oxide, 1.2 parts of film forming agent, 0.02 parts of defoamer and 42 parts of water.

[0045]The preparation method of organosilicon-modified acrylate emulsion comprises the following steps:

[0046] First, mix 0.5 parts of sodium lauryl sulfate, 0.5 parts of OP-10, 0.06 parts of sodium bicarbonate and 20 parts of water, stir for 6 minutes, then add 12 parts by weight of octamethylcyclotetrasiloxane dropwise under stirring conditions, 3 parts of methyl methacrylate and 7 parts of butyl acrylate were dropped within 2.5 hours, then 0.8 parts of dodecylbenzenesulfonic acid and 0.5 parts of ammoni...

Embodiment 3

[0059] A water-based paint for electric equipment is made of the following raw materials in parts by weight:

[0060] 30 parts of silicone modified acrylate emulsion, 24 parts of phenolic resin, 20 parts of ammonium polyphosphate, 12 parts of zinc borate, 7 parts of pentaerythritol, 14 parts of diatomaceous earth, 10 parts of expanded perlite, γ-Al 2 o 3 0.3 parts, 7 parts of graphene oxide, 1.5 parts of film forming agent, 0.02 parts of defoamer and 45 parts of water.

[0061] The preparation method of organosilicon-modified acrylate emulsion comprises the following steps:

[0062] First, mix 0.6 parts of sodium lauryl sulfate, 1.0 parts of OP-10, 0.08 parts of sodium bicarbonate and 30 parts of water, stir for 7 minutes, and then add dropwise 14 parts by weight of octamethylcyclotetrasiloxane, 3 parts of methyl methacrylate and 8 parts of butyl acrylate are dropped within 3.5 hours, then 1.0 parts of dodecylbenzenesulfonic acid and 0.5 parts of ammonium persulfate are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com