Methanol recovery method in rectification process for preparing ethylene glycol from synthesis gas and methanol recovery tower

A methanol recovery tower, methanol recovery technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of complex process, large equipment occupation, high energy consumption, optimize process pipelines, reduce The effect of thermal energy consumption and equipment space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

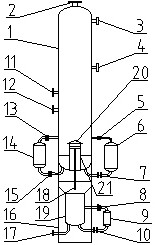

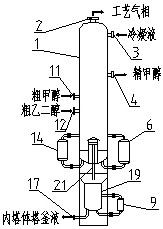

[0029] combine figure 1 , figure 2 The present invention is further described. refer to figure 1 As shown, the present invention provides a methanol recovery tower for methanol recovery in the synthesis gas-to-ethylene glycol rectification process in combination with on-site process conditions and the different characteristics of methanol content in crude methanol and crude ethylene glycol, which includes an outer tower body 1, Inner tower body 19, reboiler a14, reboiler b6 and reboiler c9, the tower diameter of described inner tower body 19 is less than the tower diameter of outer tower body 1, and inner tower body 19 is arranged on the lower end of outer tower body 1 In the skirt 16, the upper end of the inner tower body 19 is fixed on the inner wall of the skirt 16 by reducing the diameter, and the tower still of the outer tower body 1 is communicated with the tower top of the inner tower body 19; the outer tower body 1 is made of carbon steel and Made of composite mate...

Embodiment 2

[0041] (1) Crude methanol with a purity of 90% from the crude methanol storage tank and crude ethylene glycol with a purity of 85% from the crude ethylene glycol storage tank enter the outer tower body 1 from crude methanol inlet 11 and crude ethylene glycol inlet 12 respectively In the process, flow downward from the surface of the packing in the outer tower body 1 and contact the gas phase evaporated in the outer tower body for countercurrent mass transfer and heat transfer, the process gas phase flows out from the gas phase outlet 2 at the top of the outer tower body, and the refined methanol comes from the refined methanol recovery outlet 4 Flow out and enter the refined methanol storage tank;

[0042] (2) The temperature of the process gas phase at the top of the methanol recovery tower is controlled at 57°C, and the process gas phase flows out from the gas phase outlet 2 at the top of the outer tower body 1 and passes through the primary cooler of the methanol recovery to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com