Super capacitor electrode material prepared by doping carbon material and preparation method thereof

A technology of supercapacitors and electrode materials, applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of increased industrialization steps, different quality structures, unstable properties, etc. , to achieve the effect of guarantee and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

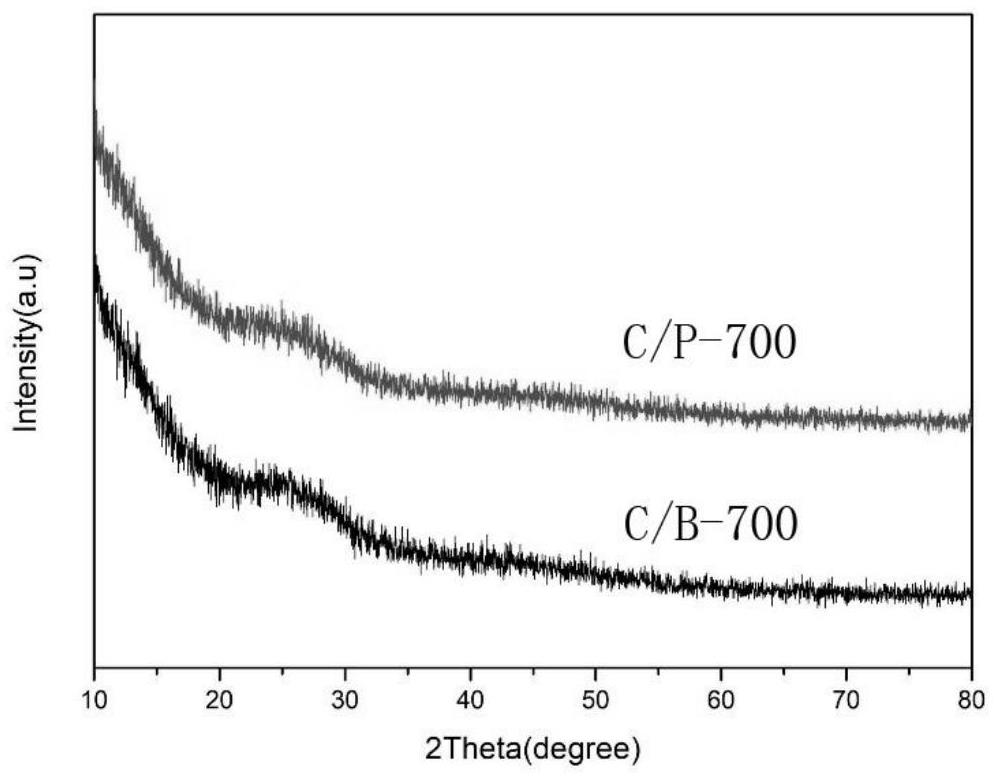

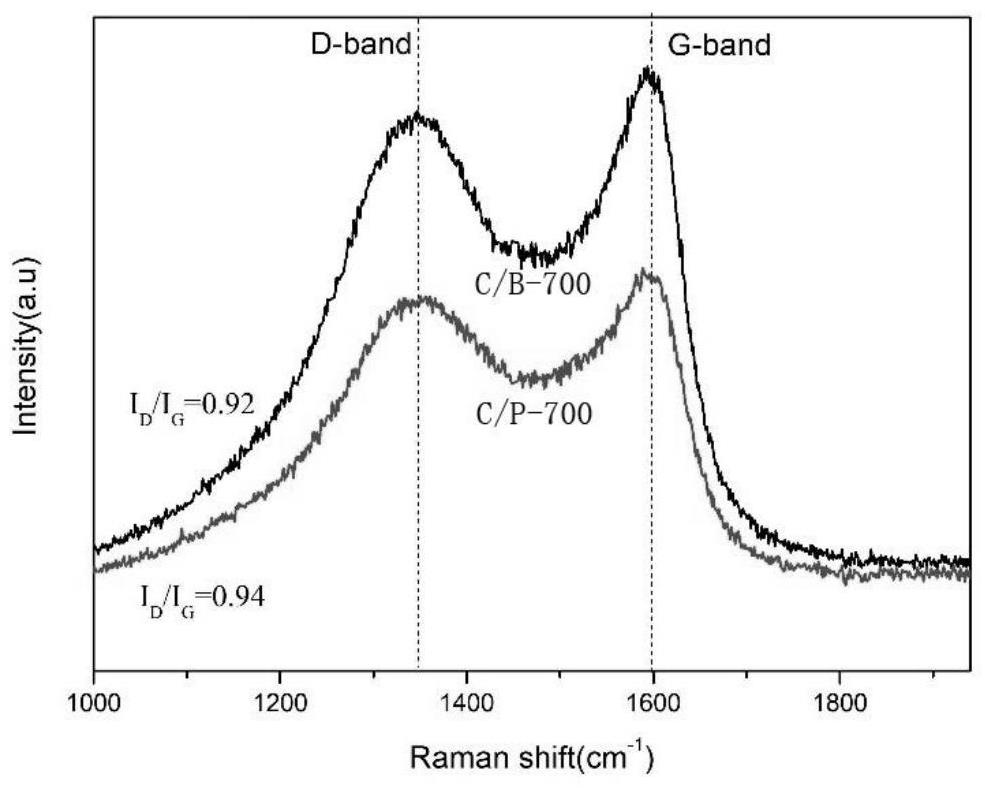

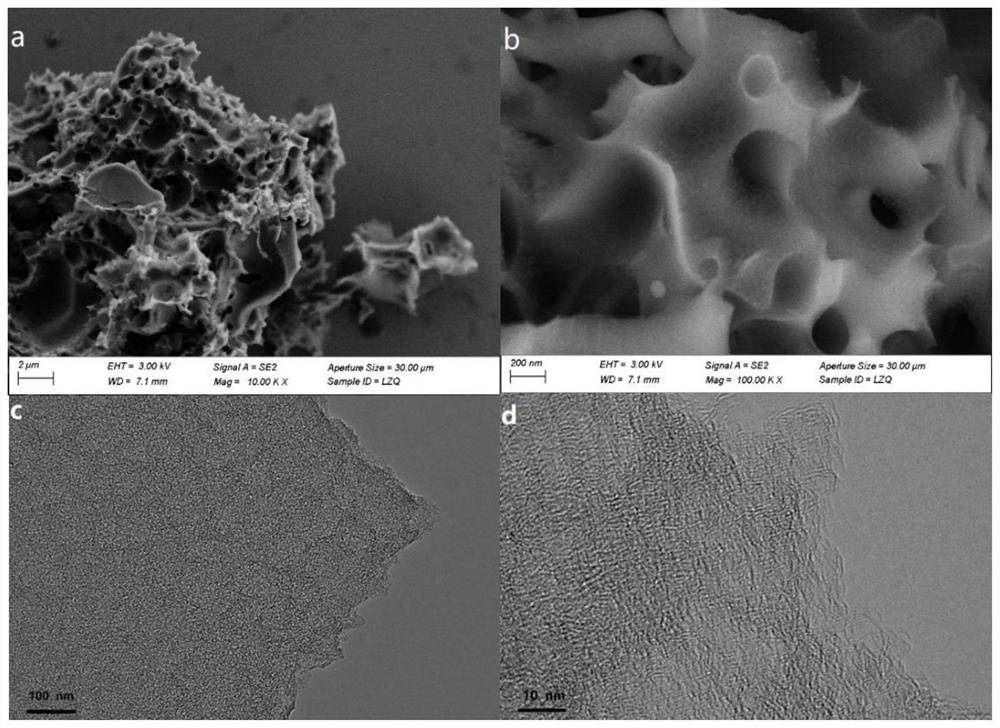

[0050] Embodiment 1: Preparation of boron-doped carbon material C / B-700.

[0051] ① Weigh 0.2294 grams (0.00052mol) of organic ligand

[0052] 4-(2,4,6-tricarboxylphenyl)-2,2':6',2”-terpyridine was placed in a 100ml beaker, and then 12ml of DMF was poured into it, and the beaker containing the mixture was placed on a magnetic stirrer Stir at constant temperature until the organic ligand is completely dissolved (about 0.5 hours) to obtain solution A;

[0053] ②According to the ratio of metal to organic ligand molar ratio of 1:2, weigh 0.0774 g (0.00026 mol) of zinc nitrate hexahydrate, measure 10 ml of deionized water to dissolve it completely, and dissolve the dissolved zinc nitrate hexahydrate solution, all added (slowly added dropwise) to the organic mixed solution A, and continued stirring at constant temperature for 1 hour to obtain solution Ba; weigh an appropriate amount of doping material 0.09642g (0.00156mol) H 3 BO 3 Dissolve it with 5ml of deionized water, then ad...

Embodiment 2

[0057] Example 2: Preparation of phosphorus-doped carbon material C / P-700

[0058] ① Weigh 0.2294 grams (0.00052mol) of organic ligand

[0059] Put 4-(2,4,6-tricarboxylphenyl)-2,2':6',2”-terpyridine in a 100ml beaker, then pour 12ml of DMF into it, and place the beaker containing the mixture on a magnetic stirrer Stir at constant temperature until the organic ligand is completely dissolved (about 0.5 hours) to obtain solution A.

[0060] ②According to the ratio of metal to organic ligand molar ratio of 1:2, weigh 0.0774 g (0.00026 mol) of zinc nitrate hexahydrate, measure 10 ml of deionized water to dissolve it completely, and dissolve the dissolved zinc nitrate hexahydrate solution, all added (slowly added dropwise) to the organic mixed solution A, constant temperature and continued to stir for 1 hour, to obtain solution Ba; 4 ) 2 HPO 4 Dissolve it with 10ml of deionized water, then add it dropwise to solution Ba, and then continue to stir for 1h to obtain solution Bb;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com