Method for preparing concrete block by utilizing composite silicon material and autoclaved aerated concrete block prepared by using method

A technology of concrete block and autoclaved aeration, which is applied in the field of building materials, can solve the problems of easy rupture of bubbles, etc., and achieve the effects of improving the mechanical strength of the product, improving the compressive performance of the product, and improving the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of method utilizing composite silicon material to prepare concrete block, comprises the following steps:

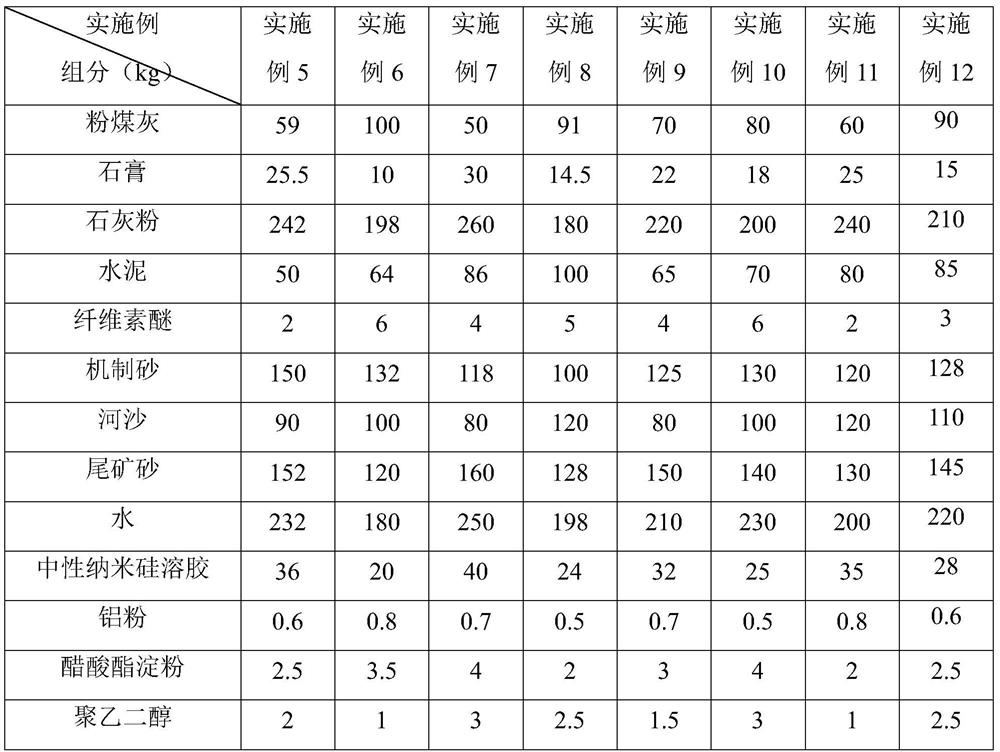

[0038] S1 Mixing: Sieve the machine-made sand with a sieve with a pore size of 250 μm, and select machine-made sand particles with a particle size not greater than 250 μm; sieve the river sand with a sieve with a pore size of 120 μm, and select river sand with a particle size not greater than 120 μm Particles: Screen the tailings sand with a sieve with a pore size of 200 μm, and select tailings sand particles with a particle size not greater than 200 μm. Weigh 125 kg of machine-made sand with a particle size of no more than 250 μm, add 100 kg of river sand with a particle size of no more than 120 μm and 140 kg of tailings sand with a particle size of no more than 200 μm, and mix evenly to obtain a composite silicon material. Weigh 20kg of gypsum, add 220kg of lime powder, 75kg of cement, 4kg of cellulose ether, 3kg of acetate starch and 2kg of ...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that the specifications and models of the neutral nano-silica sol used in embodiment 2 are different, and the neutral nano-silica sol used in embodiment 2 is the silica sol aqueous solution (Shandong Baite Co., Ltd.) that the model is LS30C40 New Materials Co., Ltd., the mass concentration of silicon dioxide is 40%, the median particle size is 30nm) and others are consistent with Example 1.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that embodiment 3 does not add starch acetate, and others are all consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com