Edible seaweed straw and preparation method thereof

A straw and seaweed technology, applied in the field of straws, can solve the problems of ecological environment damage, threats to human health, pollution, etc., and achieve the effects of strong mechanical properties and barrier properties, obvious use value, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

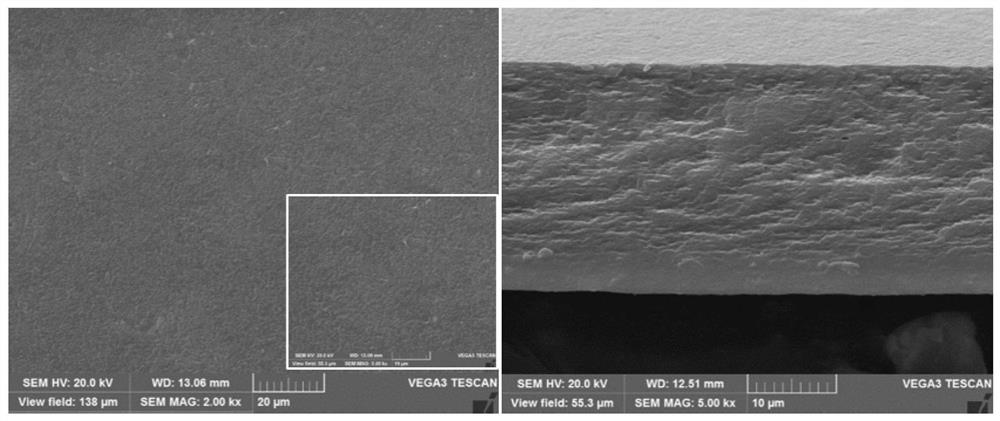

Embodiment 1

[0049] First, weigh 8.0g of sodium alginate with a viscosity of 26MPa·s, 2.0g of squash gum, and 0.1g of propylene glycol alginate, stir, add 100ml of distilled water, and continue stirring at a water temperature of 40°C-60°C until a transparent and uniform solution is formed. Then keep warm and vacuum degas until no bubbles are generated in the solution, and the viscosity of the degassed hot solution is within the range of 8000MPa·s. Use a solid stainless steel mold strip with a length of 200mm and a diameter of 7mm, smear the surface with a small amount of edible oil, then insert the mold strip into the degassed hot mixed glue solution and dip it in glue, pull out the mold strip and rotate it up and down until the glue is uniform Coat it on the stainless steel molding strip, dry it at 60°C, then immerse the dipped molding strip in the mixed solution of 2% calcium lactate and 0.5% citric acid, soak for 8 minutes, take it out with distilled water Rinse, then dry the stainless ...

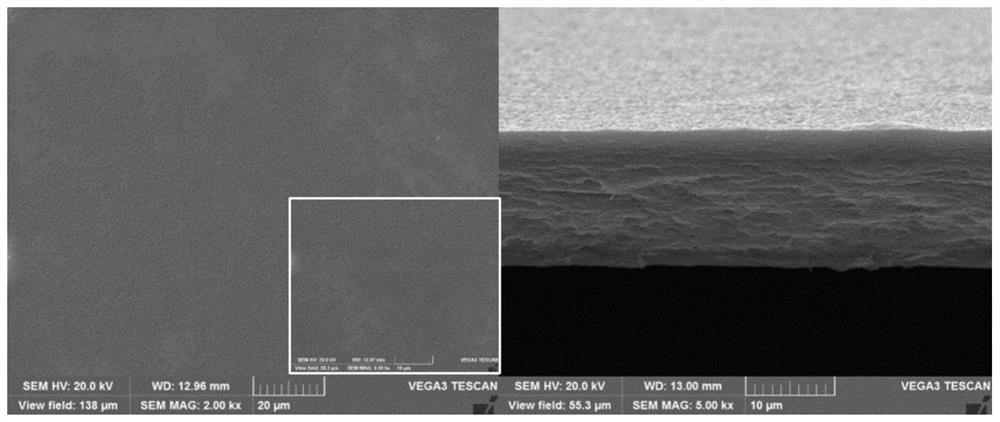

Embodiment 2

[0052] First, weigh 6.0g of sodium alginate with a viscosity of 50MPa·s, 4.0g of squash gum, and 0.15g of propylene glycol alginate, stir, add 100ml of distilled water, and continue stirring at a water temperature of 40°C-60°C until a transparent and uniform solution is formed. Then heat preservation and vacuum degassing until no bubbles are generated in the solution, and the viscosity of the degassed hot solution is within the range of 12000MPa·s. Use a solid stainless steel mold strip with a length of 200mm and a diameter of 7mm, smear the surface with a small amount of edible oil, then insert the mold strip into the degassed hot mixed glue solution and dip it in glue, pull out the mold strip and rotate it up and down until the glue is uniform Coat it on the stainless steel molding strip, dry it at 60°C, then immerse the dipped molding strip in the mixed solution of 2% calcium lactate and 0.5% citric acid, after soaking for 10 minutes, take it out with distilled water Rinse,...

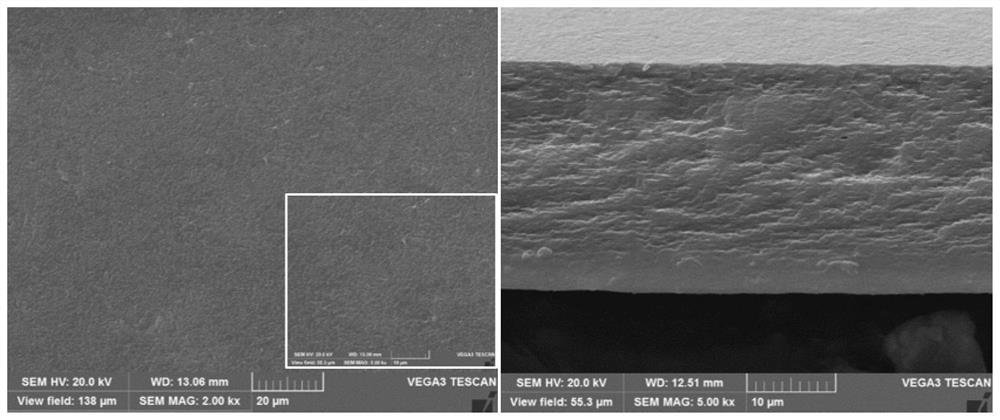

Embodiment 3

[0055] First, weigh 3.5g of sodium alginate with a viscosity of 83MPa s, 1.5g of squash gum, 0.15g of propylene glycol alginate, and 0.1g of carrageenan, stir, add 100ml of distilled water, and continue stirring at a water temperature of 40°C-60°C until Form a transparent homogeneous solution, then keep warm and vacuum degas until no bubbles are generated in the solution, and the viscosity of the degassed hot solution is within the range of 15600MPa·s. Use a solid stainless steel mold strip with a length of 200mm and a diameter of 7mm, smear the surface with a small amount of edible oil, then insert the mold strip into the degassed hot mixed glue solution and dip it in glue, pull out the mold strip and rotate it up and down until the glue is uniform Coat it on the stainless steel molding strip, dry it at 60°C, then immerse the dipped molding strip in the mixed solution of 2% calcium lactate and 0.5% citric acid, after soaking for 10 minutes, take it out with distilled water Ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com