Preparation method and application of porous titanium alloy material modified by plasma spraying composite coating

A composite coating, plasma technology, applied in the coating, metal material coating process, additive manufacturing and other directions, can solve the problems of high cytotoxicity and inconvenience for patients, and achieve the goal of improving biocompatibility and enhancing the ability of the surface to promote osteogenesis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail by specific embodiments:

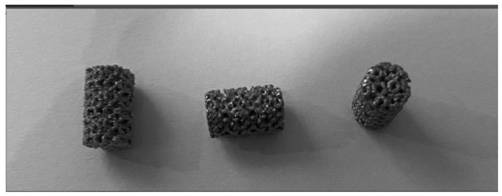

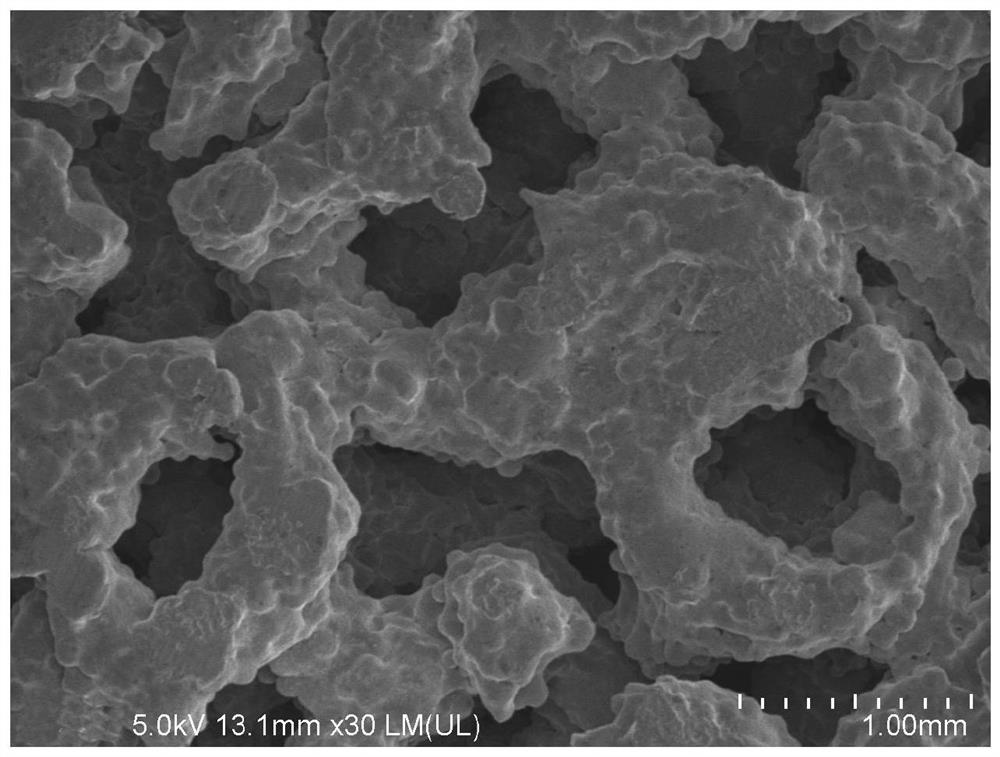

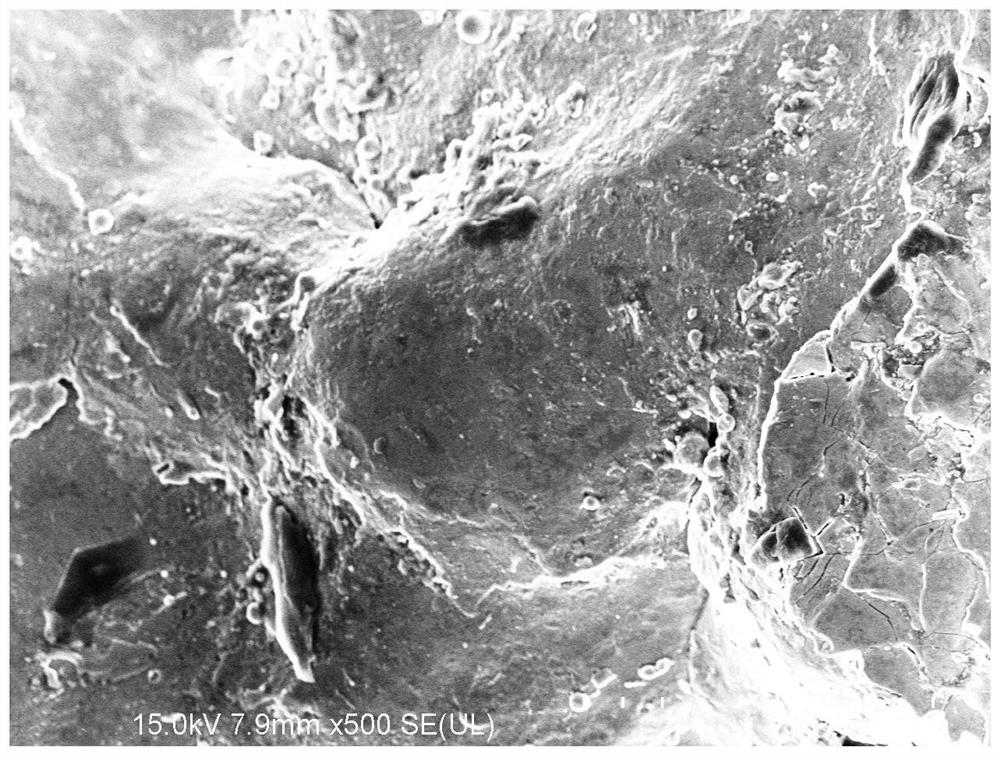

[0026] A preparation method of a porous titanium alloy material modified by a plasma sprayed composite coating, comprising the following steps:

[0027] 1. Pretreatment of titanium alloy material: sand blasting and roughening the titanium alloy sheet for standby (the sand used is 46 mesh brown corundum, Al 2 O 3 );

[0028] 2. Ball milling and granulation: four groups of composite powders were prepared according to the mass ratio of zinc oxide to 5% (group A), 10% (group B), 15% (group C), and 20% (group D). Put 50g of compound powder, 75g of ball mill beads, and dissolve in an appropriate amount of anhydrous ethanol. Large, medium and small balls are milled for 12min, and the speed is 380r / min. Ball milled twice, filtered through a 200-mesh sieve, and dried for later use.

[0029] 3. Preparation of coating by atmospheric plasma spraying: The pretreated titanium sheet is clamped on a metal cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com