Photocuring 3D printing silicon-based ceramic core and preparation method thereof

A 3D printing, ceramic core technology, applied in ceramic products, ceramic molding machines, cores, etc., can solve the problems of high core open porosity, poor process stability, difficult operation, etc., to improve the strength and open pores. The effect of increasing the open porosity and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

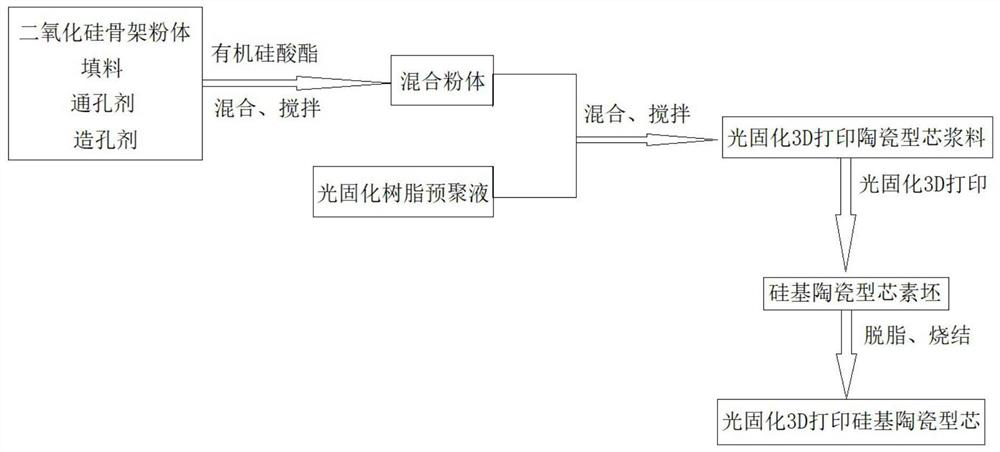

[0052] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a light-cured 3D printing silicon-based ceramic core, which mainly includes the following steps:

[0053] Step 1) Prepare photocurable 3D printing ceramic core slurry; wherein, in parts by weight, the photocurable 3D printing ceramic core slurry includes: 30-50 parts by weight of silica skeleton powder, 20-50 parts by weight Parts by weight of filler, 10-15 parts by weight of a through-hole agent, and 15-30 parts by weight of a photocurable resin premix; wherein, the through-hole agent is an organic fiber coated with organosiloxane.

[0054] In this step: in the embodiment of the present invention, 10-15 parts by weight of a through-hole agent is added to the photocured 3D printing ceramic core slurry, and the through-hole agent is an organosiloxane-coated organic fiber; here, On the one hand, the organic fibers in the organosiloxane-coated organic fibers will be oxidized...

Embodiment 1

[0071] This example prepares a light-cured 3D printing silicon-based ceramic core, wherein the raw materials and mass fractions used in this example are: 30 parts by weight of silica skeleton powder, 35 parts by weight of filler, and 10 parts by weight of through-hole agent. parts by weight, 10 parts by weight of the pore-forming agent, and 15 parts by weight of the photocurable resin premix (the volume ratio of the photosensitive resin to the second diluent is 12:3). Among them, the silica skeleton powder is SiO with a particle size of 80 μm 2 Powder, the filler is Al with a particle size of 80nm 2 o 3 Powder and ZrO with a particle size of 20nm 2 powder (among them, Al 2 o 3 Powder and ZrO 2 The mass ratio of powder is 1:3). The through-hole agent is selected from organosiloxane-coated organic fibers with a length of 1 mm and a diameter of 10 μm. The pore forming agent is silicone fiber. The photosensitive resin is methacrylate and urethane acrylate with a volume rat...

Embodiment 2

[0083] This example prepares a light-cured 3D printing silicon-based ceramic core, wherein the raw materials and mass fractions used in this example are: 40 parts by weight of silica skeleton powder, 20 parts by weight of filler, and 10 parts by weight of through-hole agent. parts by weight, 10 parts by weight of the pore-forming agent, and 20 parts by weight of the photocurable resin premix (the volume ratio of the photosensitive resin to the second diluent is 16:4). Among them, the silica skeleton powder is SiO with a particle size of 100 μm 2 Powder, the filler is Na with a particle size of 50nm 2 O powder and K with a particle size of 30nm 2 O powder (and Na 2 O powder and K 2 The mass ratio of O powder is 2:1). The through-hole agent is selected from organosiloxane-coated organic fibers with a length of 15 mm and a diameter of 20 μm. The pore forming agent is silicone fiber. The photosensitive resin is polyurethane acrylate, and the second diluent is 1,6-hexanediol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com