Adhesive suitable for high-reliability copper-clad plate of Mini LED and preparation method of adhesive

A copper-clad laminate and reliability technology, which is applied in the field of high-reliability copper-clad laminate adhesives and its preparation, can solve problems such as shortening the service life of electronic components, and achieve good machining performance and low water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

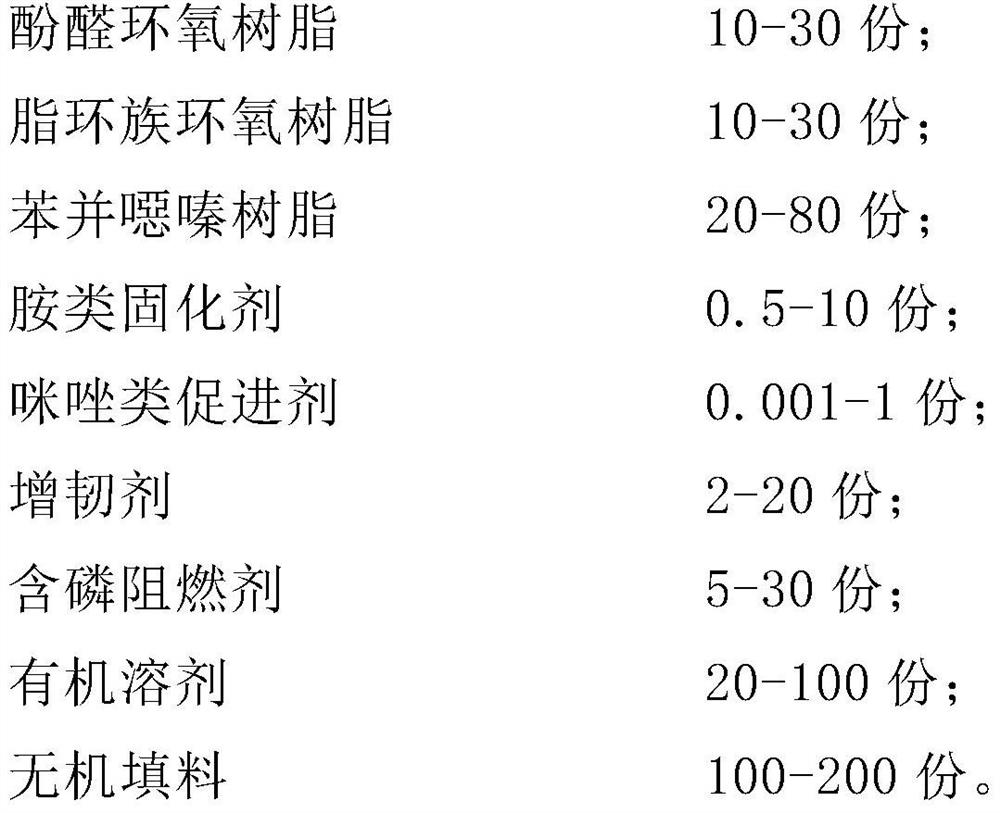

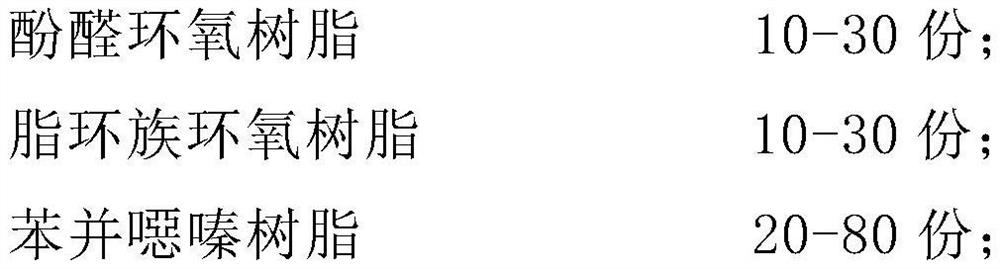

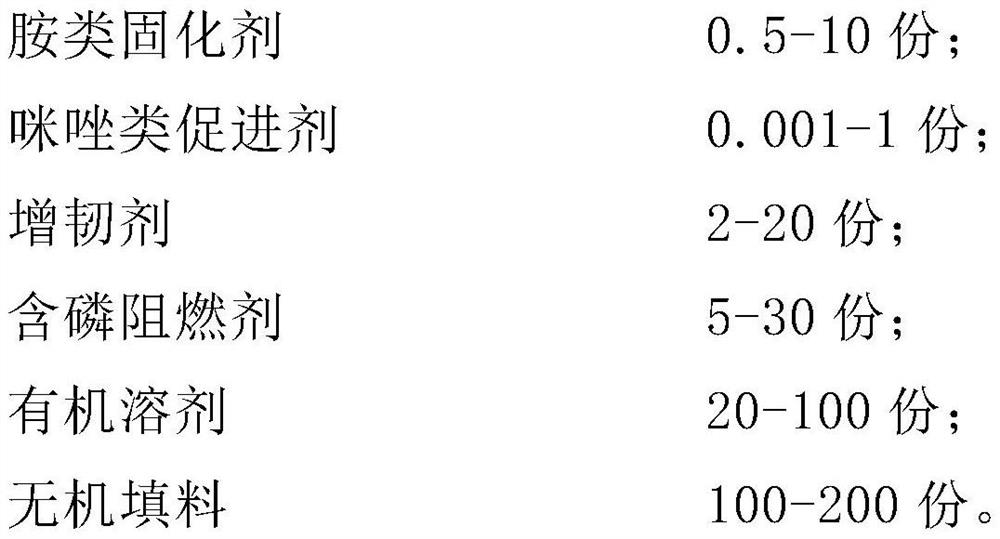

[0071] 1. Prepare materials according to the formula composition shown in Table 2:

[0072] Table 2

[0073] material name Example 1 Bisphenol A benzoxazine 60 Cycloaliphatic Epoxy Resin 10 o-cresol novolac ring 20 Amine curing agent 0.5 imidazole accelerator 0.05 Phosphorous Flame Retardants 10 Toughener 5 Soft silica powder 75 boron nitride 75 Organic solvents 50

[0074] 2. Prepare the adhesive:

[0075] Add organic solvents, flame retardants, amine curing agents, and imidazole accelerators into the mixing tank in sequence according to the formula amount, turn on the high-speed stirrer, rotate at 1000 rpm, and tank temperature at 35°C, and continue stirring for 60 minutes after the addition is completed;

[0076] Add benzoxazine resin, cycloaliphatic epoxy resin, novolac epoxy resin, and toughening agent successively according to the formula amount in the stirring tank and stir for 120 minutes at a ...

Embodiment 2

[0093] 1. Prepare materials according to the formula composition shown in Table 3:

[0094] table 3

[0095]

[0096]

[0097] 2. Glue adjustment:

[0098] Add organic solvents, flame retardants, amine curing agents, and imidazole accelerators into the mixing tank in sequence according to the formula, turn on the high-speed stirrer at a speed of 1200 rpm, and tank temperature of 45°C. After the addition is complete, continue stirring for 80 minutes;

[0099] Add benzoxazine resin, cycloaliphatic epoxy resin, novolac epoxy resin and toughening agent successively according to the formula amount in the stirring tank and stir for 100 minutes at a speed of 1000 rpm;

[0100] Weigh the inorganic filler according to the formula, add it into the stirring tank and stir for 3 hours at the speed of 1200 rpm, and then the adhesive is prepared.

[0101] 3. Glue baking:

[0102] The adhesive made by impregnating 7628 type E-glass glass fiber cloth is selected, and the semi-cured ad...

Embodiment 3

[0116] 1. Prepare materials according to the formula composition shown in Table 4:

[0117] Table 4

[0118] material name Example 3 Bisphenol A benzoxazine 80 Cycloaliphatic Epoxy Resin 25 O-Cresol Novolak Epoxy 15 Amine curing agent 5 imidazole accelerator 0.5 Phosphorous Flame Retardants 10 Toughener 8 Soft silica powder 80 boron nitride 100 Organic solvents 30

[0119] 2. Glue adjustment:

[0120] Add organic solvents, flame retardants, amine curing agents, and imidazole accelerators into the mixing tank in sequence according to the formula, turn on the high-speed stirrer, rotate at 130 rpm, and tank temperature at 40°C, and continue stirring for 120 minutes after the addition is completed;

[0121] Add benzoxazine resin, isocyanate-modified epoxy resin, phenolic novolac resin, and toughening agent successively according to the formula amount in the stirring tank and stir for 180 minutes at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance | aaaaa | aaaaa |

| Solder heat resistance | aaaaa | aaaaa |

| Copper foil peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com