Hydrogen sulfide corrosion resistant low alloy material as well as preparation method and application thereof

A hydrogen sulfide-resistant, low-alloy technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as poor performance, and achieve the effect of improving corrosion resistance, low production cost, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

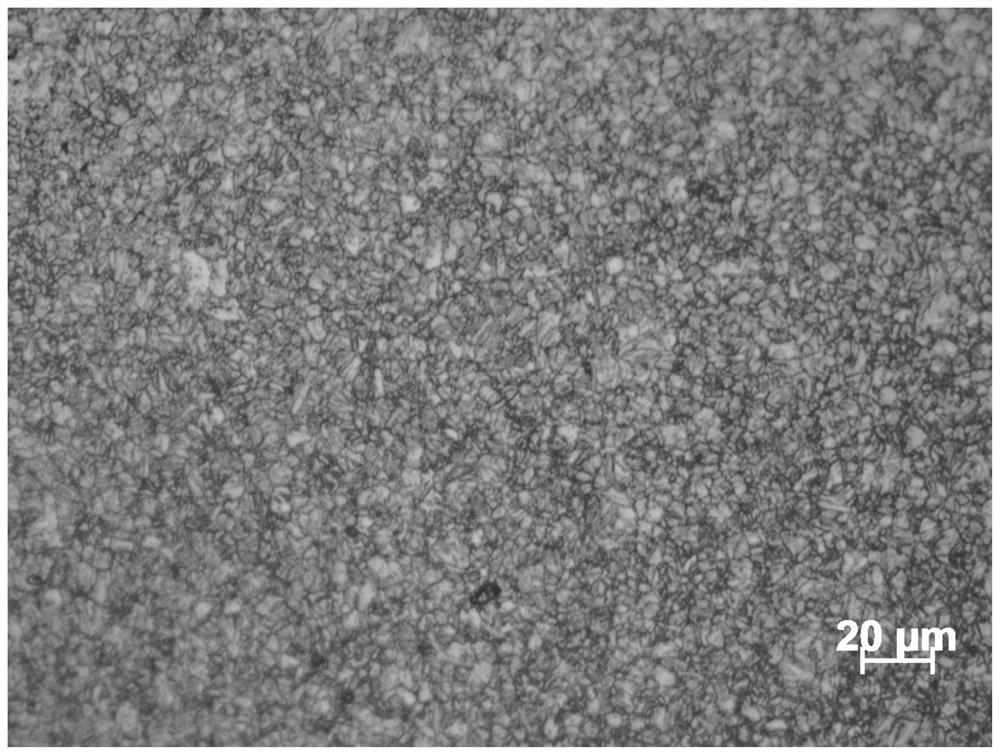

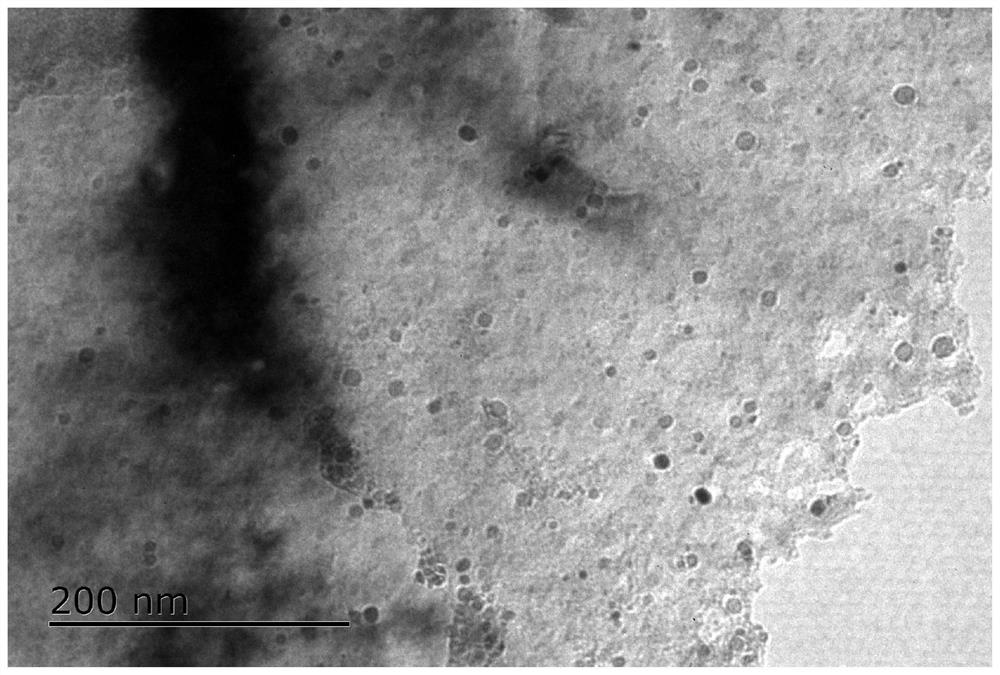

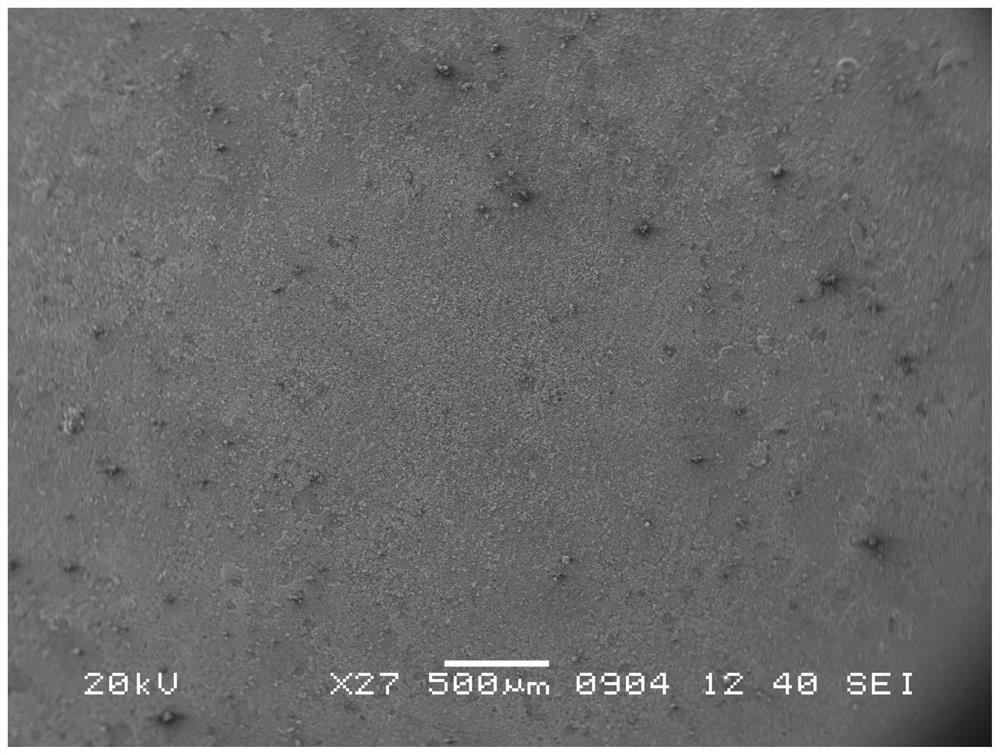

Image

Examples

Embodiment 1

[0032] an anti-H 2 Low-alloy material corroded by S surface, the composition by mass percentage is: C 0.05%, Si0.22%, Mn 0.9%, Mo 0.22%, Al 0.02%, P 0.004, S 0.002%, Ti 0.03, Nb 0.03 , W0.03, the rest is Fe.

[0033] The continuous casting slab smelted in the blast furnace is transported to the heating furnace by means of hot charging and hot delivery for reheating. The heating temperature is 1160°C, and the temperature is kept at this temperature for 65 minutes. After heating, the continuously cast slab is transported to the high-speed wire rod rolling unit for hot rolling experiment by conveying rollers, and finally rolled into an intermediate billet with a circular cross section. The initial rolling temperature is 1120°C, and the final rolling temperature is 854°C. The wire rod coming out of the high-speed wire rod rolling mill is accelerated cooling with high-speed water, and the final water cooling temperature is 805°C. Subsequently, accelerated air is used for cooling,...

Embodiment 2

[0038] an anti-H 2 Low-alloy material corroded by S surface, the composition by mass percentage is: C 0.06%, Si0.23%, Mn 0.9%, Mo 0.22%, Al 0.02%, P 0.004, S 0.002%, Ti 0.07, Nb 0.05 , W0.05, the rest is Fe.

[0039]The continuous casting slab smelted in the blast furnace is transported to the heating furnace by means of hot charging and hot delivery for reheating. The heating temperature is 1178°C, and the temperature is kept at this temperature for 70 minutes. After heating, the continuous casting slab is transported to the high-speed wire rod rolling unit for hot rolling experiment by conveying rollers, and finally rolled into an intermediate billet with a circular cross section. The initial rolling temperature is 1130°C, and the final rolling temperature is 860°C. The wire rod coming out of the high-speed wire rod rolling mill is accelerated cooling with high-speed water, and the final water cooling temperature is 810°C. Subsequently, accelerated air is used for cooling,...

Embodiment 3

[0044] an anti-H 2 Low-alloy material corroded by S surface, the composition by mass percentage is: C 0.08%, Si0.25%, Mn 1%, Mo 0.25%, Al 0.02%, P 0.005, S 0.002%, Ti 0.09, Nb 0.07 , W 0.05, the rest is Fe.

[0045] The continuous casting slab smelted in the blast furnace is transported to the heating furnace for reheating by means of hot charging and hot delivery. The heating temperature is 1190 ° C, and the temperature is kept at this temperature for 72 minutes. After heating, the continuously cast slab is transported to the high-speed wire rod rolling unit for hot rolling experiment by conveying rollers, and finally rolled into an intermediate billet with a circular cross section. The initial rolling temperature is 1160°C, and the final rolling temperature is 875°C. The wire rod coming out of the high-speed wire rod rolling mill is accelerated cooling with high-speed water, and the final water cooling temperature is 815°C. Subsequently, accelerated air is used for cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com