Method for preparing ceramic particle reinforced aluminum-based composite coating through plasma transferred arc wire spraying

A ceramic particle and reinforced aluminum-based technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problem of low flying speed of arc spraying particles, poor bonding strength between coating and substrate, and reduced service life of coating and other problems, to achieve the effect of improving bonding strength and compactness, excellent corrosion resistance and wear resistance, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

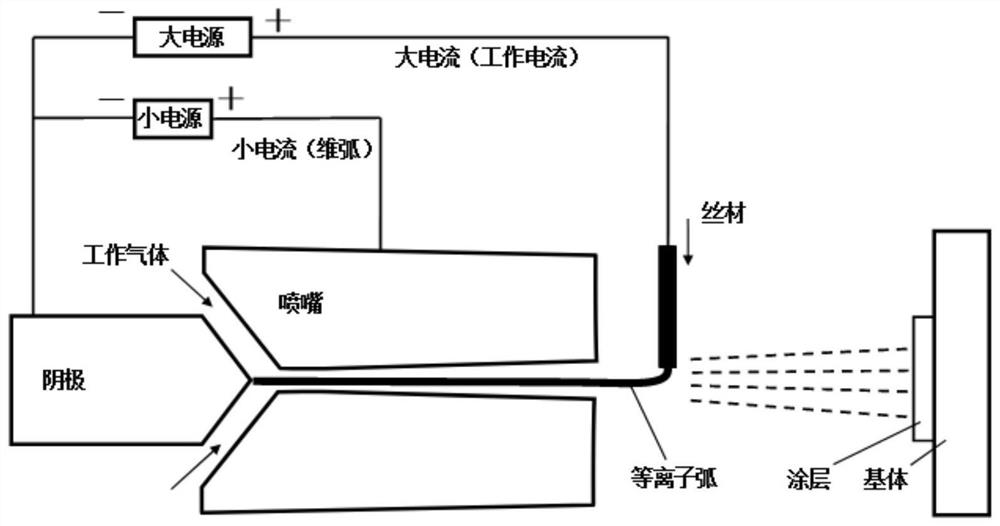

Method used

Image

Examples

Embodiment 1

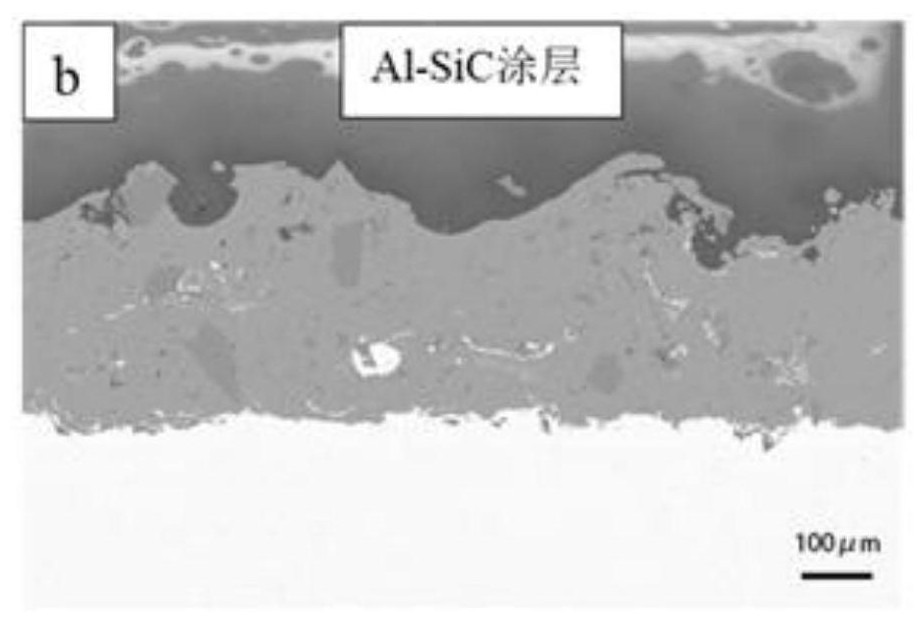

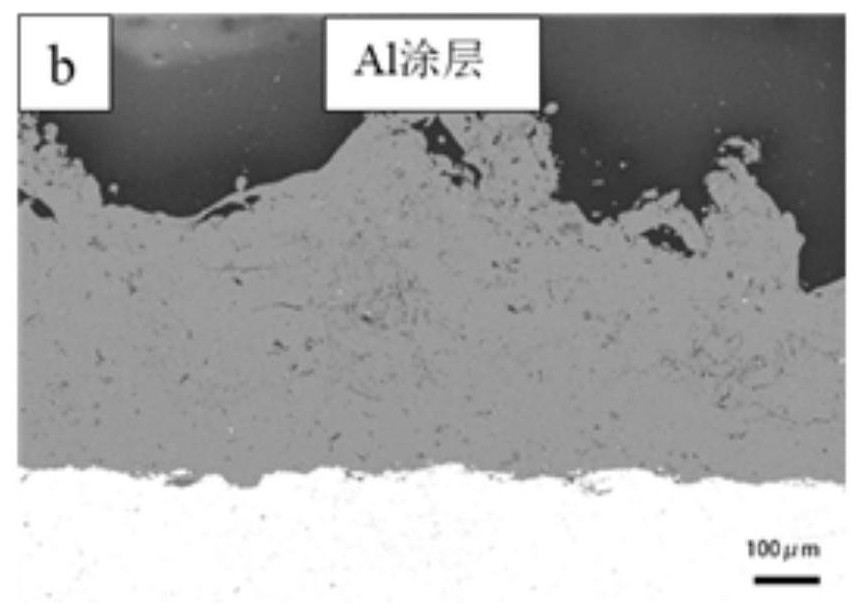

[0050] Using a rectangular 316 stainless steel plate of 50×10×1mm as the base material, the surface of the long stainless steel strip used as the base material is first degreased, decontaminated, polished and derusted, then ultrasonically cleaned with acetone, and then put into a drying oven for drying , and then perform sandblasting on the surface, and then use compressed air to blow off the sandblasted substrate. The plasma transfer arc wire material spraying process is adopted, and the Al-based powder core wire material (filled with 27% SiC powder) with a diameter of 2mm is used as the spraying raw material, and the aluminum-based ceramic composite coating is sprayed on the surface of the substrate of the above-mentioned pretreated surface. The specific process parameters are: the sum of the working current and the maintenance arc current is 150-160A, the flow rate of the main gas (argon gas) is 115-120L / min, the flow rate of the auxiliary gas (hydrogen gas) is 6L / min, the p...

Embodiment 2

[0052] Using a 10×10×1mm square 316 stainless steel plate as the substrate, the surface of the stainless steel as the substrate is first degreased, decontaminated, polished and derusted, and then ultrasonically cleaned with acetone. After cleaning, it is placed in a drying oven to dry, and then Sandblast the surface, and then use compressed air to blow off the sandblasted substrate. The plasma transfer arc wire spraying process is adopted, and the Al-based powder core wire material (filled with 27% SiC powder) with a diameter of 2mm is used as the spraying raw material, and the aluminum-based ceramic composite coating is sprayed on the surface of the substrate of the above-mentioned pretreated surface. The specific process parameters are: the sum of the working current and the maintenance arc current is 150-160A, the flow rate of the main gas (argon gas) is 115-120L / min, the flow rate of the auxiliary gas (hydrogen gas) is 6L / min, the powder core wire and the nozzle The distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average binding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com